Custom Made CNC Machining Turning Spline Tooth Gear

Weifang Karry Plastic Products Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:Internal Gear

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Spur Gear

- Material:Stainless Steel

=== Base Info ===

- Model NO.:WF-JF

- Type:Worm And Wormwheel

- Item:Customized Machining Gears

- Raw Material:Stainless Steel, Carbon Steel

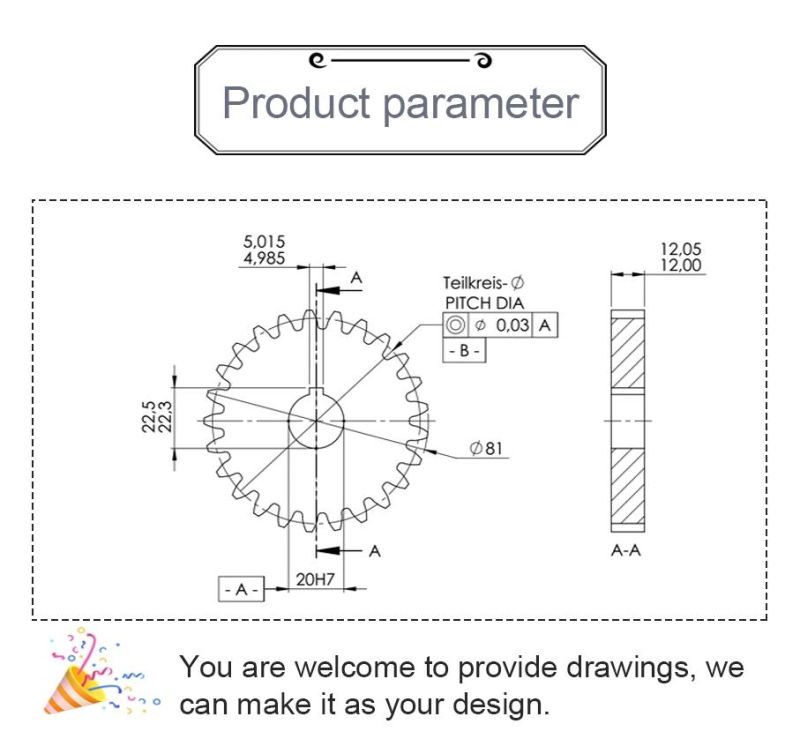

- Size:as Your Requirement

- Techincs:Machining

- Brand Name:Shengao,OEM

- Standard or Nonstandard:Nonstandard

- Factory:Over 15 Years Experience in Producing

- Precisoin:High

- Inspection:Differential Planetary Gear

- Surface Treatment:Hobbing,Shaving,Grinding

- OEM Service:Yes

- Custom Made:Yes

- Logo Printing:Customized

- MOQ:10-1000PCS

- Free Sample:Yes

- Transport Package:Plywood Box

- Specification:SGS, ISO9001: 2008, EN124, ASTM, DIN, GB, CE

- Trademark:Shengao

- Origin:Weifang City, Shandong Province, China

- HS Code:87089910

- Production Capacity:50000PCS,Year

=== Description ===

Capacity

Major Products:

Major Products:spur gear; worm gear; bevel gear; planetary gear; gear; metal gear; cycle gear; pinion gear; gear

manufacturing; helical gear; custom gear; spiral bevel gear; rack and pinion gear; mechanical gears;

transmission gears; rack gear; spiral gear; work gear; gear reducer; richmond gear; hypoid gear; gear

wheels; pulleys and gears; motive gear; gear teeth; truck gear; gear system; involute gear;

PRODUCT DESCRIPOTION

1. Crown wheel and pinion gears and spiral bevel gears for automobile rear axle, truck, tractor

front/rear axle and tool.

2. Raw material: 20CrMni 22CrMo 8620 SCM420

Processing: Forging, normalizing, rough, machining, fine finishi, carburizing, tempering,

annealing, accurate grinding, matching and testing, packing.

3. The tooth surface is finished by lapping machine, the color will be silver gray

4. Hardness about surface: HRC58-62, internal: HRC35-40.

5. We can process gears according to customers drawing and samples.

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues, Thread

and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc.

( Detection accuracy to 0.001 millimetre )

| Mininum of Quantity | 100 Piece/Pieces |

| Unit Weight | 0.5kg~300kg |

| Price | FOB Qingdao,China,USD1.5~1.9 |

| Packing Details | Paper Box in Wooden Pallet |

| Delivery Time | One month |

| Payment Terms | L/C, T/T |

| Machining | CNC or |

| Supply Capacity | 50 Metric Tons per Month |

| Standard | DIN,ASTM,GOST,B |

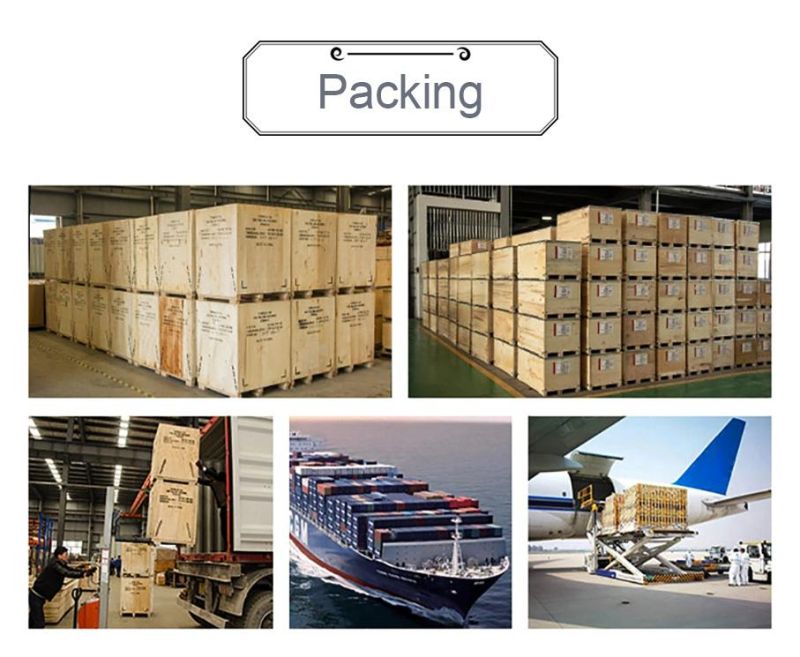

Packing:

Packing:1: Shrink film+ bulk loading

2: Shrink film +Carton box + Pallet/ wooden case

3: PP + Wooden case

4: As per customers' requirements or negotiated

1. Q: Why choose Shengao product?

A: We shengao have our own plant-- Weifang Shengao machinery Co.,Ltd, therefore, we

can surely promise the quality of every product and provide you comparable price.

2. Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

3. Q: Do you provide customized gears?

A: Yes. Customers give us drawings and specifications, and we will manufacture accordingly.

4. Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

You can look through our website to find your interest or email your any questions through

below approach! We will reply to you within 12 hours.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23