Hycnc 12.7 mm 1/2 Tungsten Carbide CNC Lathe Milling Cutters Wood Router Bits End Mill for Spindle High Speed Engraving

Xiamen Fuhom Light Industrial Co., Ltd. / 2022-06-09

- Coating:Coating

- Tooth Form:Straight Tooth

- Tooth Space:Extra Dense Tooth

- Structure:Indexable Type

- Material:Boron Nitride

- Type:T Milling Cutter

=== Base Info ===

- Model NO.:12.7 Mm 1,2

- Transport Package:Carton

- Specification:carton

- Trademark:HYCNC

- Origin:China

- HS Code:8467991000

- Production Capacity:100PCS,Day

=== Description ===

Basic Info.

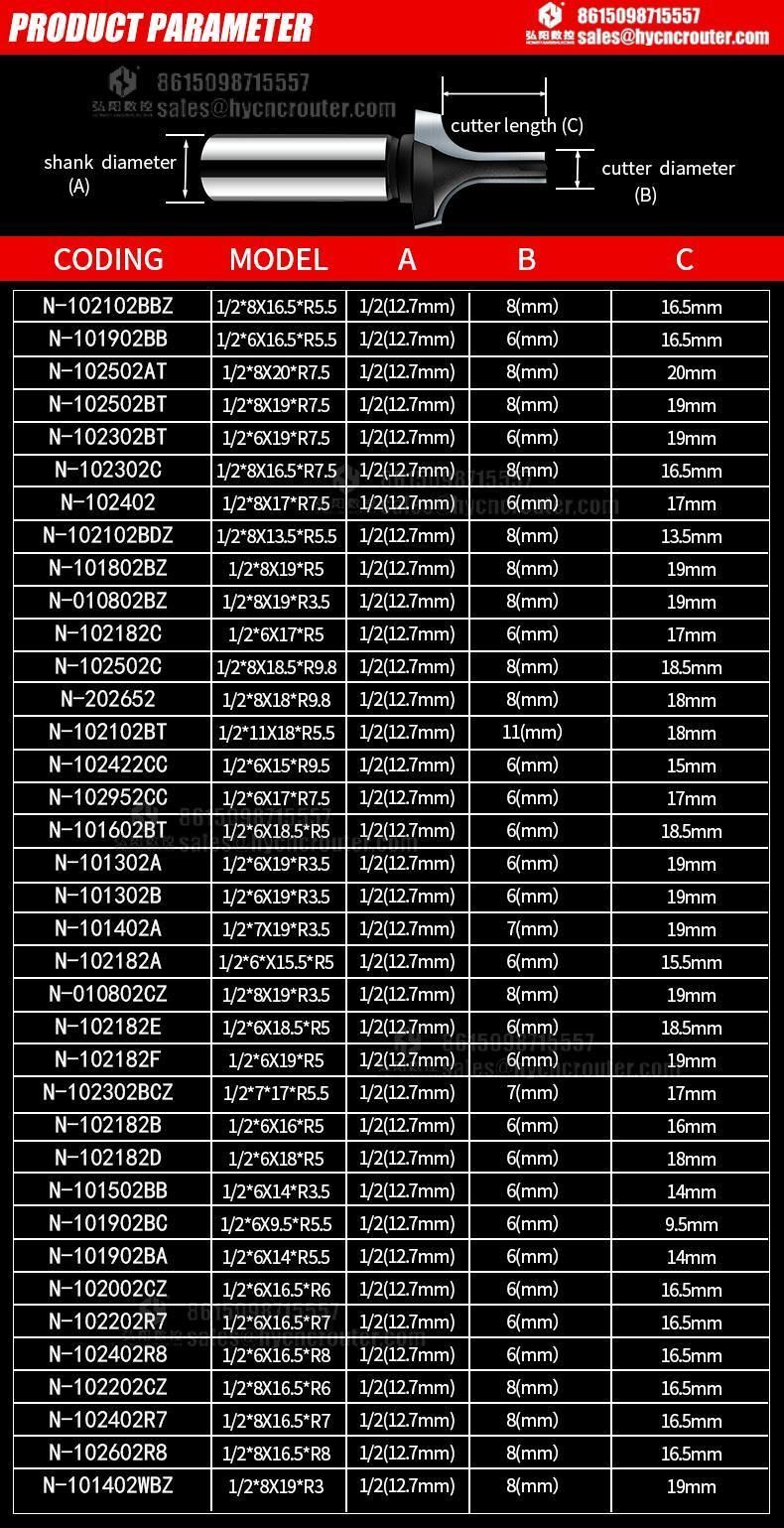

Model NO. 12.7 Mm 1/2 Transport Package Carton Specification carton Trademark HYCNC Origin China HS Code 8467991000 Production Capacity 100PCS/DayProduct Description

Hycnc 12.7 Mm 1/2 Tungsten Carbide Cnc Lathe Milling Cutters Wood Router Bits End Mill For Spindle High Speed Engraving

1.The blade is made of high-hardness tungsten steel material, and the cutting edge is finely ground, which is not only sharp, but also more wear-resistant and not easy to break the blade.2.The cutter head and the cutter handle are welded with high frequency, which is durable and easy to break the cutter, which greatly improves the service life of the cutter.

1.The blade is made of high-hardness tungsten steel material, and the cutting edge is finely ground, which is not only sharp, but also more wear-resistant and not easy to break the blade.2.The cutter head and the cutter handle are welded with high frequency, which is durable and easy to break the cutter, which greatly improves the service life of the cutter.

USE OF KNIVESTool selection

To achieve the purpose you require, be sure to use short-edged tools as much as possible. Too long cutting edge or too long tool body will cause vibration and deflection during machining, which will cause damage to the tool and affect the quality of machining. We recommend using a tool with a larger shank diameter.Tool maintenance

(1) Keep theTool maintenance knives clean, after use, remove the residue of the knives after engraving, and use standard

industrial solvents to clean the knives (2) Applying a small amount of engine oil can prevent the tool surface from rusting and clean up all the stains on the tool handle to prevent slippage during use (3) Do not sharpen the tool and change the shape of the tool without authorization, because each grinding process requires professional grinding equipment and professional grinding skills, otherwise it is easy to cause the cutting edge to break and cause accidents.Packing & Delivery

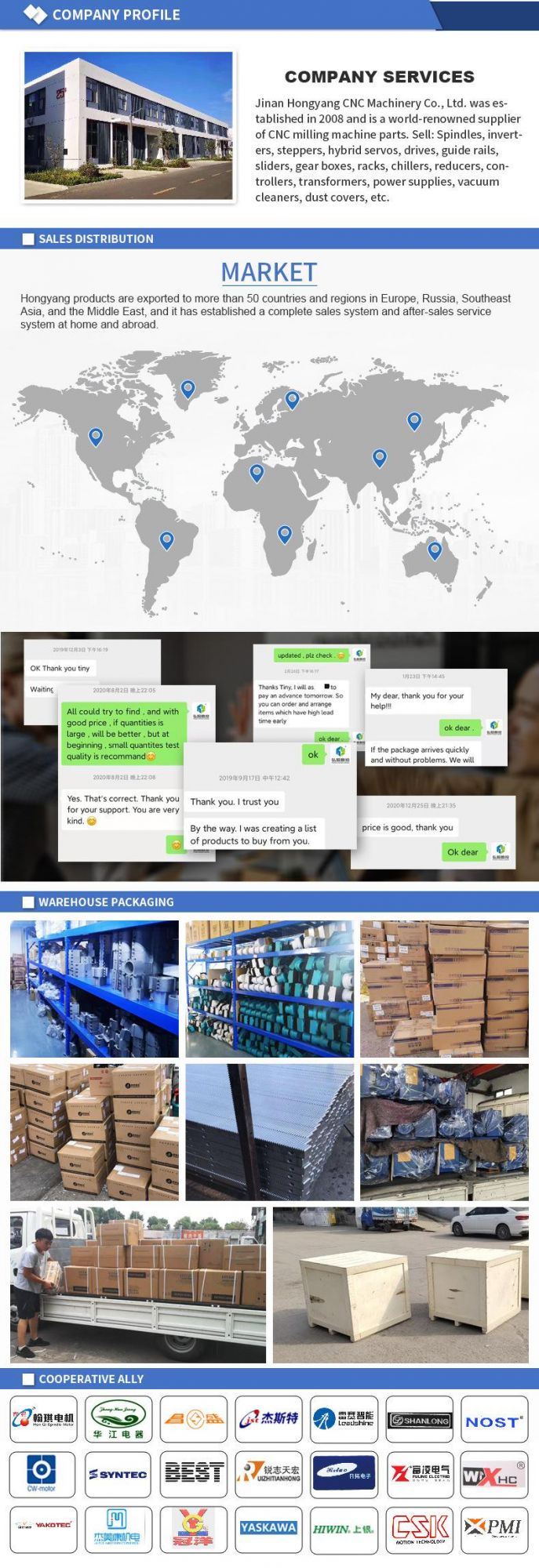

Company Profile

Company Profile

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23