Fricwel Auto Parts Clutch Lining Compounded Fiber Clutch Facing High Quality Clutch Facing Factory Price Fw-028

Guangzhou Wangda Co., Ltd. / 2022-06-24

- After-sales Service:Avaliable

- Warranty:One Year

- Part:Clutch Facing

- Material:Compounded Fiber

- Classification:Friction Clutch

- Certification:ISO,TS16949:2002

=== Base Info ===

- Model NO.:FW-028

- Stroke:Other

- Usage:Heavy Duty Trucks, Car, Racing Cars

- Working Mode:Power Combining

- Working State:No linkage

- Voltage:0

- Electromagnetic Clutch:0

- Feature:Low Wearing Rate

- Transport Package:Carton+Pallet

- Specification:GB,T 5764-2018

- Trademark:Fricwel

- Origin:China

- HS Code:8708931

- Production Capacity:400, 000 PCS,Month

=== Description ===

Basic Info.

Model NO. FW-028 Stroke Other Usage Heavy Duty Trucks, Car, Racing Cars Working Mode Power Combining Working State No linkage Voltage 0 Electromagnetic Clutch 0 Feature Low Wearing Rate Transport Package Carton+Pallet Specification GB/T 5764-2018 Trademark Fricwel Origin China HS Code 8708931 Production Capacity 400, 000 PCS/MonthProduct Description

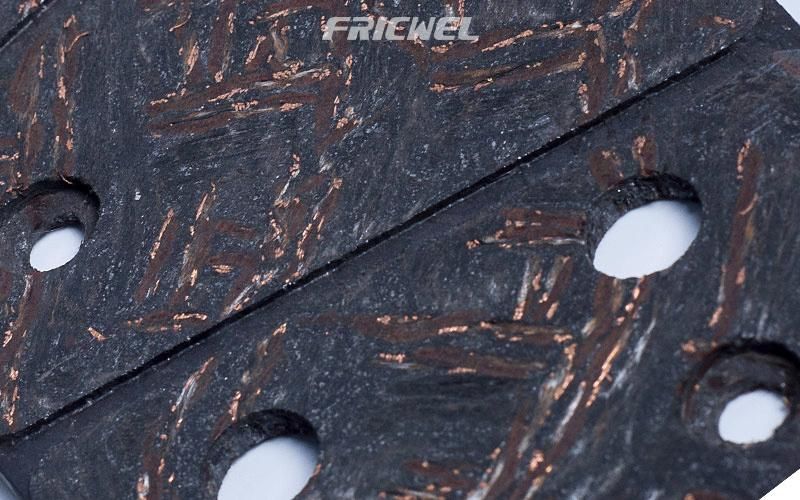

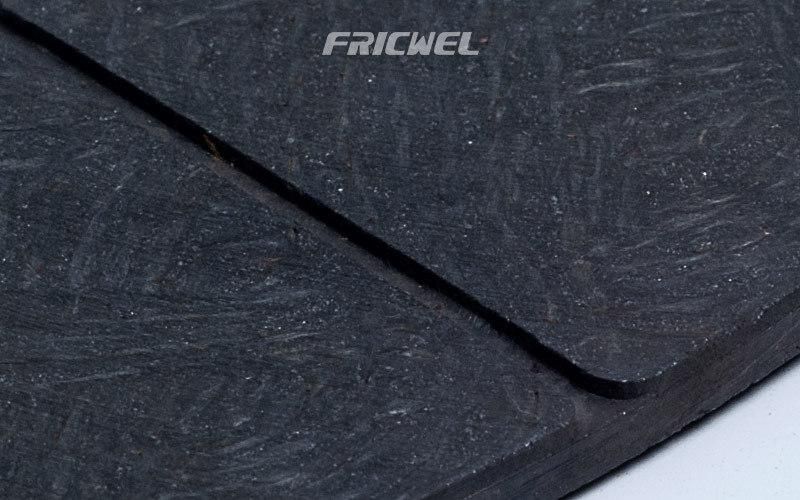

FW-028 Coumpounded fiber material clutch facing.Related Products:

Products Performance And Advantage:

1. Clutch facing average coefficient of friction is 0.45-0.55, excellent anti slippage property.

2. Low wearing rate, average data is 0.05-0.15, longer life time.

3. Theory density for clutch lining is 2.0 g/cm3, actual density is 1.87 g/cm2.

4. Product hardness is HRL 50, suitable hardness and no hurting for the flywheel.

5. Burst strength is 14000 r/m forφ200×130×3.5mm, all materials can pass this standard.

6. Bending test for clutch lining material 40 N/mm2.

7. Wide range of products, size ∅100mm-∅440mm.

8. All kinds of material available: glass fiber, covering yarn, high copper yarn, Kevlar fiber, strong twisting yarn, also round circle appearance and European material appearance.

9. Suitable for clutch disc assembly used in heavy duty truck, light truck, passenger cars, racing cars and tractors.

10. The delivery date will be about 45 days after receiving the advance payment, and the packaging will be in strong export cartons+non-wooden pallets.

Dimensions And Specifications:

| No. | O.D*I.D (MM*MM) | Thickness (MM) | Grooves | No. | O.D*I.D (MM*MM) | Thickness (MM) | Grooves |

| 1 | 141*82 | 3.2-5.0 | NO | 21 | 260*167/170 | 3.2-5.0 | 18/27/30 |

| 2 | 145*105 | 3.2-5.0 | NO | 22 | 270*165/170 | 3.2-5.0 | 18 |

| 3 | 150*110 | 3.2-5.0 | 16 | 23 | 275*170/175/180 | 3.2-5.0 | 18/24/24*3 |

| 4 | 160*110 | 3.2-5.0 | 16-18 | 24 | 280*165/170 | 3.2-5.0 | 18/24 |

| 5 | 165*90 | 3.2-5.0 | 18 | 25 | 295*170/175/180 | 3.2-5.0 | NO/18 |

| 6 | 170*110/120 | 3.2-5.0 | 16-18 | 26 | 300*165/180/190 | 3.2-5.0 | 16/18/200 |

| 7 | 178*100 | 3.2-5.0 | 6 | 27 | 302*165/190/197 | 3.2-5.0 | NO/18/24 |

| 8 | 180*100/125 | 3.2-5.0 | 16-18 | 28 | 310*175/180/190 | 3.2-5.0 | NO/18/20 |

| 9 | 186*126 | 3.2-5.0 | 18 | 29 | 325*180/185/190/200/210 | 3.2-5.0 | NO/18/20 |

| 10 | 190*132/135 | 3.2-5.0 | NO/16-24 | 30 | 330*185 | 3.2-5.0 | 12 |

| 11 | 200*130/135/140 | 3.2-5.0 | NO/24/16*2 | 31 | 340*175 | 3.2-5.0 | 18 |

| 12 | 202*145 | 3.2-5.0 | 24 | 32 | 350*187/195/200/216/220 | 3.2-5.0 | 6/16/18/24 |

| 13 | 210*134/135/141 | 3.2-5.0 | NO/24 | 33 | 352*216/217 | 3.2-5.0 | 22 |

| 14 | 215*130/140/145/155 | 3.2-5.0 | NO/16/24/27 | 34 | 380*200 sector | 4.1/4.4 | 92° |

| 15 | 225*130/140/150/155 | 3.2-5.0 | NO/18/2416*2 | 35 | 380*190/200/206/240/250 | 3.2-5.0 | NO/16/18/24 |

| 16 | 228*150/155 | 3.2-5.0 | NO/16/24 | 36 | 400*220/2308247/249/250 | 3.2-5.0 | NO/13/18/24 |

| 17 | 236*150 | 3.2-5.0 | 24*2/18 | 37 | 410*250/260 | 3.2-5.0 | 18 |

| 18 | 240*150/152/160/185 | 3.2-5.0 | NO/18/24 | 38 | 420*220 | 3.2-5.0/3.6/4.6 | 24/106°/92° |

| 19 | 250*155/160/165 | 3.2-5.0 | NO/24/27 | 39 | 430*230/240/250/261 | 3.2-5.0 | NO/18/24 |

| 20 | 254*150/155 | 3.2-5.0 | 6*2/18/24 | 40 | 440*280 | 3.2-5.0 | 18 |

Production Environment:

Company Profile:

Founded in 1992, our factory covers an area of more than 20,000 square meters, with an annual output of about 1,000 tons. Our main business is the production and sales of auto parts products, such as clutch facings, copper clutch buttons, friction disc and related accessories. We are also one of the earliest friction material manufacturers in China.

Our factory has passed ISO9001 quality system certification. And we have various advanced lathes and processing equipments, as well as various engineering testing instruments,reaching the leading level in the domestic industry. Our products are exported to all over the world and well received by customers.

Why Choose Us?

1. Focus on friction materials production for more than 20 years.

2. Strict quality control system and professional inspection, OEM service avaliable.

3. One year quality gurantee since the date of delivery.

4. The product has passed CE, ISO and TS16949 certificates.

5. Professional online service team, quick response for customer message and question.

6. Sales markets covers North America, South Aemica, Europe,Asia, Middle east and Africa.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23