CMP Ds-201kf/Hb88107A Driveshaft Center Support Bearing 35mm for Dodge Ford Gmc Chevy

Xiamen Hongju Industry & Trade Co., Ltd. / 2022-06-24

- Type:Drive Shaft Bearing

- Material:Steel+Rubber

- Certification:ISO9001, VDA6.1

- ABS:Without ABS

- Brand:Morgan

- Transport Package:Box

=== Base Info ===

- Model NO.:HB88107A

- Specification:40*57.15*168.28mm

- Trademark:Morgan

- Origin:China

- HS Code:8708999990

- Production Capacity:100000units,PCS

=== Description ===

Basic Info.

Model NO. HB88107A Specification 40*57.15*168.28mm Trademark Morgan Origin China HS Code 8708999990 Production Capacity 100000units/PCSProduct Description

Description:Center Bearing is installed at the bottom center of vehicle, and used to support the driving shaft, it consists of bearing, bracket, rubber cushion and flingers etc., the good sealing performance of bearing can ensure long working life.

Application:

Item Number | HB88508, 210866-1X(Spincer No.) |

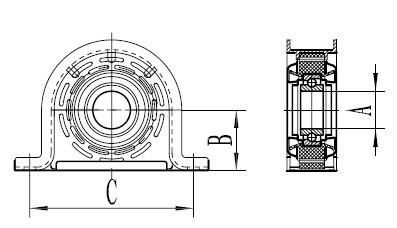

Bearing ID (A) | 35MM 1.3780inch |

Mounting Width (C) | 168.28MM 6.625inch |

Center Line Height (B) | 57.15MM 2.25inch |

Application | Chevrolet, GMC,Ford |

Characteristics:

The main performance of plastic coating:

- Spalling resistance

- Moisture proofing

- Corrosion proof

- Rust proof

- Lubricated for life ball bearing with metal reinforced seals

- Water resistant grease between the bearing and bearing caps providing an additional barrier from moisture and contaminants

- Available for domestic and import automotive and light truck applications

- Components are sample inspected at each process to insure all dimensional and visual specifications are met with 100% final inspection prior to packaging assuring the highest level of quality

How to Replace a Driveshaft Center Support Bearing

Step 1: Remove the front driveshaft. The front driveshaft is attached to the transmission output shaft and connected by four bolts.

On some rear wheel drive vehicles, the bearing block bolts thread into nuts that are solidly mounted or welded onto the frame. On some vehicles, two part nuts and bolts are used to attach the rear of the front driveshaft to the center support bearing.

Step 2: Remove the bolts. Get the correct size end wrench or socket wrench to do this.

Step 3: Remove the front part of the driveshaft. The front driveshaft is going to be attached solid inside the output shaft supports.

In order to remove the driveshaft, you'll need a rubber or plastic tipped hammer. On the front of the driveshaft is a welding mark that is solid and is the best place to hit with the hammer to loosen the driveshaft. Using the hammer and with your other hand supporting the driveshaft from underneath, hit the weld mark solidly. Repeat until the drive shaft is loose and can be removed from the front.

Step 4: Remove the bolts attaching the front driveshaft to the center support bearing. Once the bolts are removed, the front driveshaft will be detached from the center support bearing.

Step 5: Place the front driveshaft in a secure area. This will keep it from being damaged or misplaced.

Step 6: Remove the rear driveshaft. The rear driveshaft is attached to the rear end yoke.

Step 7: Remove the rear driveshaft. Remove the bolts that attach the two components together first; then carefully remove the driveshaft from the yoke using the same method as the front driveshaft.

Step 8: Remove the center clip that attaches the rear driveshaft to the center support bracket. This clip is removed with a straight-edge screwdriver.

Carefully unscrew this and slide behind the rubber boot for future use.

- Warning: If you remove the clamp all the way, it will be very difficult to correctly replace it; which is why it's recommended above to buy a new replacement clamp that you can reinstall to attach the rear driveshaft to the center support bearing.

Step 9: Remove the boot. After you've removed the clamp, slide the boot from the center support bearing.

Step 10: Remove the center support bearing housing. Once you've removed the rear driveshaft, you'll be ready to remove the center housing.

There are two bolts on top of the housing that you'll need to remove. Once both bolts are removed, you'll be able to slide the front driveshaft and rear input shaft easily from the center bearings.

Step 11: Remove the old bearing. The best way to accomplish this step is to have a professional machine shop remove and professionally install the new bearing.

They have access to better tools that allow them to complete this job easily than most DIY mechanics. Listed below are the steps to follow if you don't have access to a machine shop or choose to undertake this step on your own.

Step 12: Remove the bolts. Remove the ones that connect the front portion of the driveshaft to the rear driveshaft.

Step 13: Secure the forward part of the driveshaft. Secure it into a bench vise.

Step 14: Unscrew the center nut. This is the nut that will hold the connecting plate on the shaft where the center bearing is placed.

Step 15: Tap the worn out center support bearing off the driveshaft. Use a hammer and brass center punch.

Step 16: Clean the ends of the driveshaft. Once the center support bearing has been removed, clean all ends of each driveshaft with solvent and prepare to install the new bearing.

- Warning: Improper installation of the center support bearing can lead to serious damage to the transmission, rear gears, and axles. When in doubt, contact a local ASE certified mechanic or machine shop to professionally install the center rear bearing.

Step 17: Install new bearing. This is the most critical part of this job. Again, if you're not 100 percent confident, have a professional machine shop install the new bearing. It can save you a tremendous amount of stress and money.

Step 18: Apply grease. Add a thin layer of recommended grease onto the bearing shaft to ensure proper lubrication and to allow the bearing to slide on much easier.

Step 19: Push the bearing onto the shaft as straight as possible. Utilize a rubber or plastic tipped hammer to guide the bearing onto the driveshaft.

Step 20: Check bearing installation. Verify that the bearing spins easily on the driveshaft without any wobbles or movement.

Step 21: Reinstall center support bearing and driveshaft. This is the easiest part of the job, as all you need to do is reinstall each section in reverse order that you followed with the installation.

First, reattach the center support bearing to the frame.

Second, insert the rear driveshaft into the spline, replace boot over the spline, and reattach the clamp.

Third, reattach the rear driveshaft to the yoke; making sure to align the marks on both the rear driveshaft and the yoke before inserting bolts. Tighten all bolts to manufacturers recommend torque pressure settings. Verify that all bolts and nuts are tight before proceeding.

Fourth, reattach front of driveshaft to the transmission output shaft, again verifying the alignment marks previously made. Tighten all bolts to manufacturers recommend torque pressure settings. Verify that all bolts and nuts are tight before proceeding

Fifth, grab the front driveshaft where it attaches to the center support bearing and verify that it is securely fastened. Complete the same check with the rear driveshaft

Step 22: Remove all tools, used parts and materials from under the vehicle. This includes jack stands from each wheel; place the vehicle back onto the ground.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23