Garage Tire Changer with Assist Arm

Tenda Enterprise Holdings Co., Limited / 2022-06-23

- Warranty:14month

- Structure:All Tires

=== Base Info ===

- Model NO.:C9583s

- Power Source:Pneumatic

- Type:All Tires

- Automatic:Automatic

- Standard:All Tires

- Certification:CE

- Condition:Yuanmech

- Product Name:Best Selling Vehicle Equipment Tire Changer with a

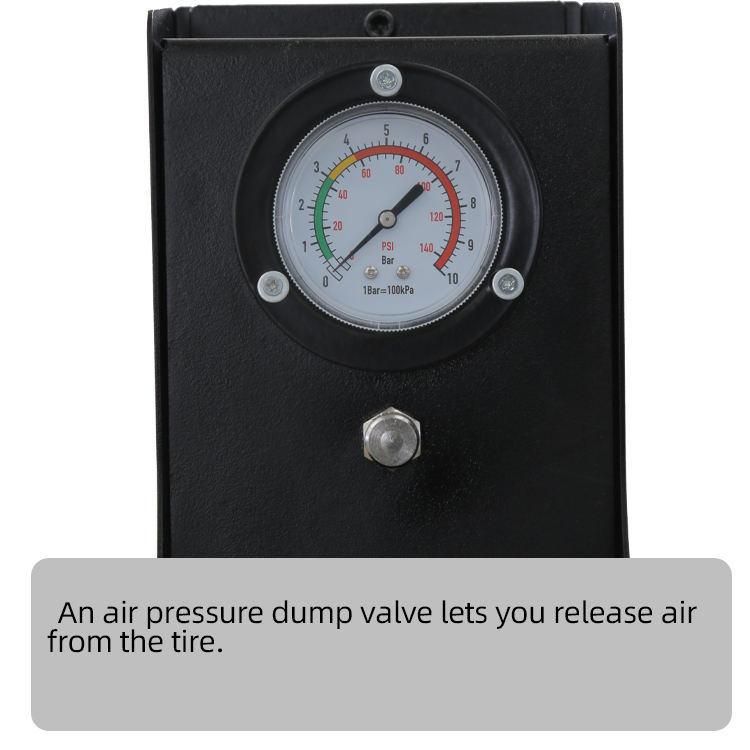

- Working Pressure:8-10 Bar,117-145psi

- Outside Clamping:10-24"

- Inside Clamping:12-26"

- Max. Wheel Width:3-15"

- Max. Wheel Diameter:1100mm

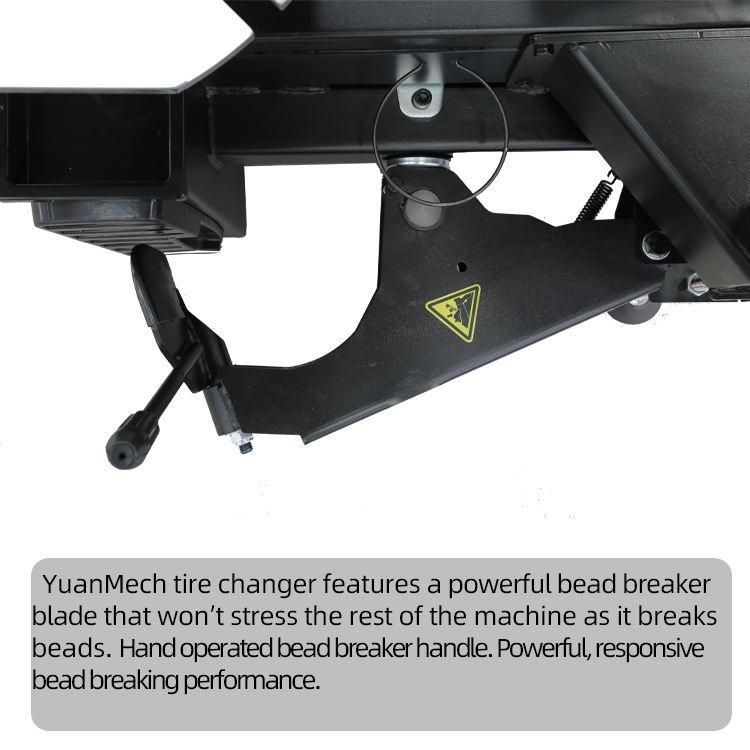

- Bead Breaker Force:2800kg

- Color:Customized Color Acceptable

- Weight Machine:N.W:265kg G.W:280kg

- Transport Package:Plywood

- Specification:100cm*950cm*100cm

- Trademark:YuanMech

- Origin:Yingkou, Liaoning, China

- Production Capacity:3000

- Package size per unit product:100.00cm * 950.00cm * 100.00cm

- Gross weight per unit product:280.000kg

=== Description ===

Why Choose UsProducts Description

Customer Sevice

FAQ

FAQ

1. How to make sure the calibration is performed successfully?

Use a well-balanced calibration wheel. After calibration leave the wheel on, run the wheel in Dynamic mode several times, and apply random weight both inside and outside. Check if the wheel balancer machine show the weight and if the weight is always at 6 o'clock position. (Please contact us if you need operation video)

2. For wheel balancer machine, what are the common causes of chasing weight problem?

The wheel is not centered properly so it wobbles during rotation which cause chasing weight.

The weight is not placed in correct position in Alu mode, especially on the inner plane.

Lost accuracy and require calibration.

3. For wheel balancer machine, what are the difference between static imbalance and dynamic imbalance?

A static imbalance exists when the tire has a heavy part. The dynamic imbalance is different. A dynamic imbalance exists when a tire has two heavy parts which are located diagonally.

4. What are the common test programs inside wheel balancer machine software?

Common tests are: piezoelectric sensor test, Encoder test, Distance/Diameter/Width measurement sensor test, keyboard test, display test, motor test (Please contact us if you have more questions on this topic)

5. What are common problem when using motorcycle adaptor?

The common problem with motorcycle/adaptor is the shaft strength. With heavy or big wheel, the thin shaft jumps during rotation, which cause a bad balancing result. (Please contact us if you have more questions on this topic)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23