Long Lift Hb Standard Magnetic Hysteresis Brakes with High Speed Range

Desheng International Industry Co., Ltd. / 2022-06-24

- Type:Brake System

- Material:Steel

- Position:Rear

- Main Market:Western Europe

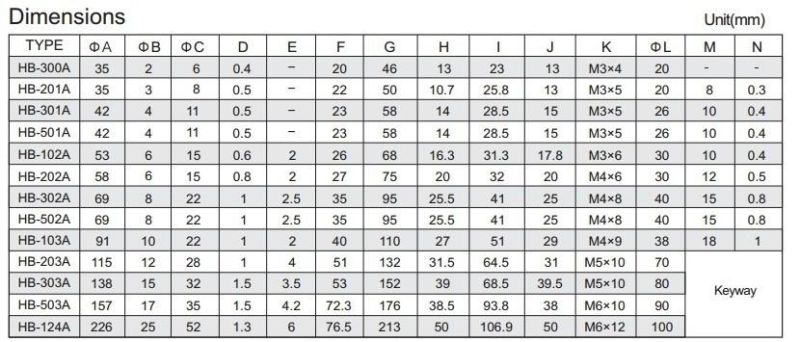

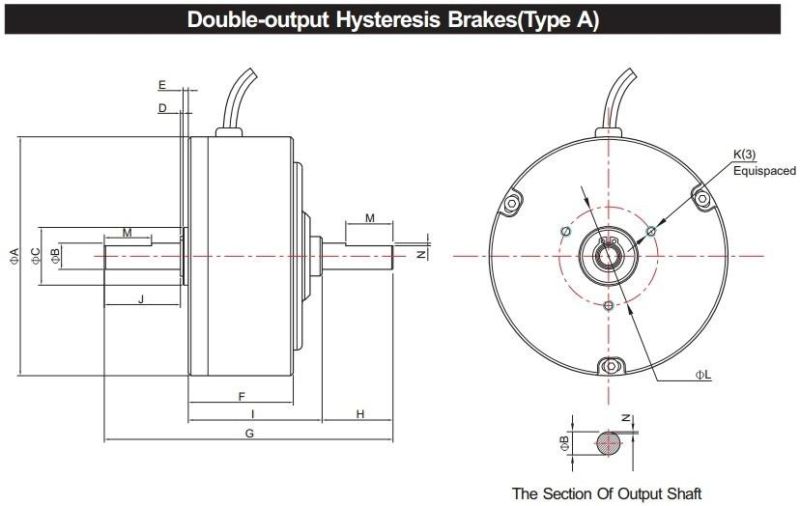

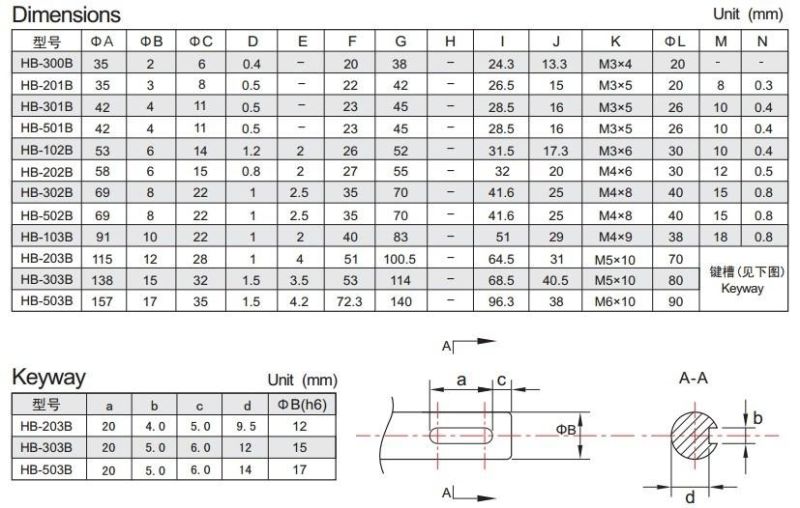

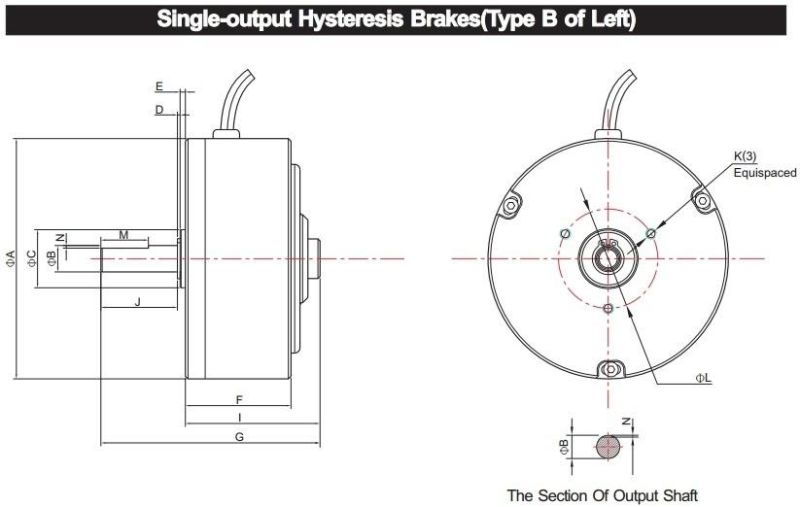

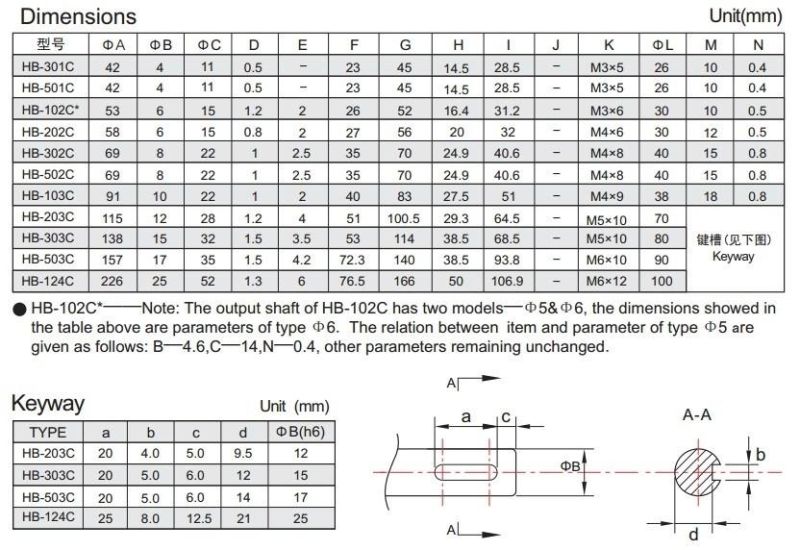

- Size:as Our Catalogue

- Weight:Depends on The Model

=== Base Info ===

- Model NO.:HB-501

- Working Temperature:0~ 40 Centigrade

- Operating Humidity:30%~95%

- Service Life:10000h

- Applicatio:Applied in Various Machine

- Feature:High Speed and Long Service Life

- Export Market:Global

- Transport Package:Carton with Foam

- Specification:ROHS

- Trademark:KIMCHEN

- Origin:China

- Production Capacity:5, 000set,Month

=== Description ===

Basic Info.

Model NO. HB-501 Working Temperature 0~ 40 Centigrade Operating Humidity 30%~95% Service Life 10000h Applicatio Applied in Various Machine Feature High Speed and Long Service Life Export Market Global Transport Package Carton with Foam Specification ROHS Trademark KIMCHEN Origin China Production Capacity 5, 000set/MonthProduct Description

Product Description

Hysteresis Brakes for Coil Winding Machinery(Magnetic brake)

Standard Hysteresis Brakes produce torque strictly through a magnetic air gap without the use of magnetic particles or friction components. This method of braking provides far superior operating characteristics (smoother torque, longer life, superior repeatability, high degree of controllability, and less maintenance and down time) which make them the preferred choice for precise tension control during the processing of nearly any material, web or strand.

Structural Characteristics:

The hysteresis effect in magnetism is applied to torque control by the use of two basic componentsa reticulated pole structure and a specialty steel rotor/shaft assemblyfastened together but not in physical contact. Until the field coil is energized, the drag cup and shaft can spin freely on its bearings. When a magnetizing force from either a field coil or magnet is applied to the pole structure, the air gap becomes a flux field. The rotor is magnetically restrained, providing a braking action between the pole structure and rotor.

Applications

1.KIMCHEN Hysteresis Brakes provide precise control of wire tension during wind, hook and cut operations of high speed automated winding machines.

2.Transformer and coil winding operations employing Hysteresis Brakes in open loop control for maintaining precise tension during winding process.

3.Precision gap control using Hysteresis Brake and photo sensor.

4.Unwind tension control by means of follower arm with potentiometer, Hysteresis Brake and controller.

5.KIMCHEN Hysteresis Brakes offer frictionless, non-breakaway force for tensioning materials during slitting and many other material processing operations.

6.KIMCHEN Hysteresis Brake is used in precision computerized diagnostic equipment, as well as in regular exercise machines.

7.KIMCHEN Hysteresis Brakes are widely used in load simulation applications for life testing on electric motors, actuators, small gas engines, gearboxes, and many other rotating devices and assemblies. The ability of hysteresis devices to withstand high temperatures for prolonged periods of operation without suffering any degradation to their magnetic structures makes them ideal for these applications, as well as environmental testing, and even applications in outer space.

8.Their ability to produce torque independent of speed makes Hysteresis Brakes the preferred method of braking employed in many dynamometers used for performance testing of motors, actuators, gas engines, etc.

9.KIMCHEN Hysteresis Brake used for holding of backdriving load,applying pre-loads for preventing backlash, backdriving loads, and in limiting torque to prevent damage to delicate assemblies.

We offer other specifications and special products as your request.

Contact Information

| Salesperson | Sunny |

| TEL | +86 769 86018114 |

| FAX | +86 769 86015646 |

| Mobile | +86 13480019755 |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23