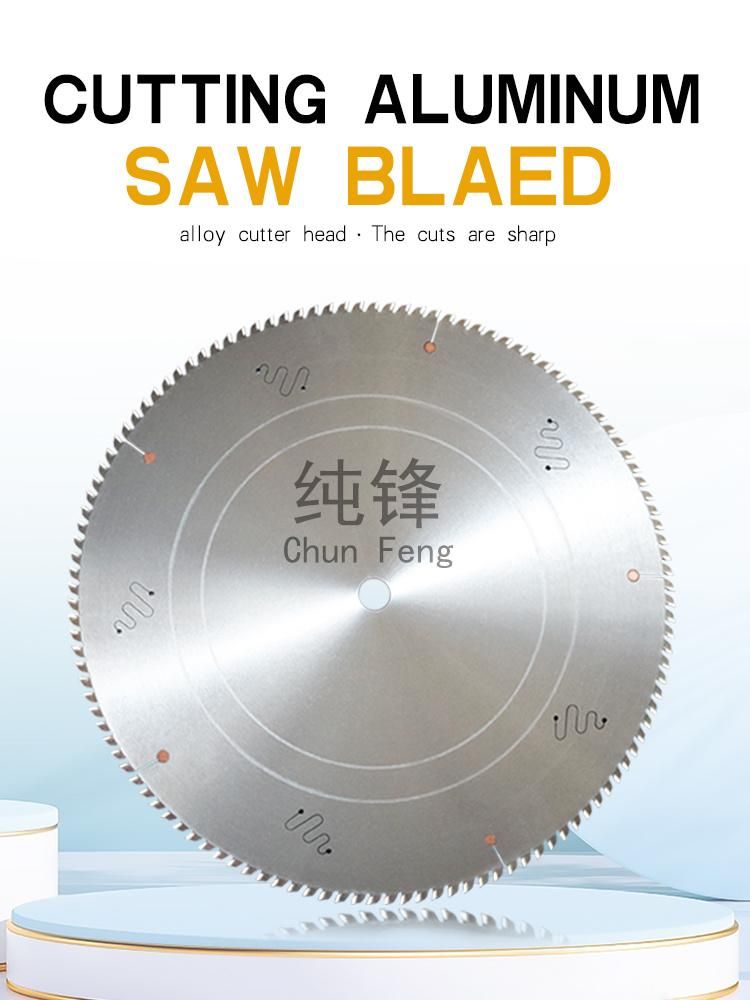

General Use Tungsten Carbide Tipped Tct Aluminum Cutting Circular Saw Blade

UPET GROUP CO., LTD. / 2022-06-09

- Tooth Form:Inverted Trapezoidal Tooth

- Diameter:355mm

- Function:Aluminum,Copper,Iron,Wood,Metal Cutting

- Shape:Circular Saw Blade

- Coating:White Steel Saw Blade

- Type:Carbide Saw Blade

=== Base Info ===

- Model NO.:14inch

- Service:Customized Size

- Blade Diameter:150mm-900mm

- Teeths:40t,48t,60t,72t,80t,96t,100t,120t,140

- Grade:Industrial

- Advantage:Precise Cut, Improved Efficiency,Long Life

- Cutter Head:Carbide Tips

- Product Name:Tct Carbide Aluminum Cutting Circular Saw Blade

- Tooth Type:Ladder Flat Tooth,Left and Right Teeth

- Process Type:Laser Welded

- Sample:Provided Costly

- Application:Machine Tool

- Delivery Time:5-10 Days

- Model Number:355mm

- Experience:More Than Ten Years

- Inner Hole:25.4,32,30,40mm

- Transport Package:Carton Box

- Specification:355-3.0-25.4,32mm-80T

- Trademark:Chunfeng

- Origin:Guangdong, China

- Production Capacity:10000pieces,Month

=== Description ===

Overview

Product Description

Detailed Photos

Company Profile

Our Advantages

After Sales Service

After Sales Service

1.Sawing sticky aluminum?

Whether the installation of the saw blade is accurate and in place, and the tightness is moderate.

2.Aluminum cut card aluminum?

According to the specifications of cutting aluminum, whether the selected saw blade specifications and models are suitable.

3.sawing with burrs?

Saw and cut aluminum specifications, and whether the cutting speed set by the equipment processing is appropriate.

4.saw with scratches?

Whether the lubrication system of the aluminum cutting equipment is reasonable, good and effective.

5.Spray lubrication is not in place?

Whether the design of aluminum cutting equipment is professional and reasonable.

6.saw blade drop?

Adjust the quality of the lubricating oil and the injection position.

7.Saw blades are not durable?

The welding teeth of the saw blade are not strong or the material is not good.

Tips:Saw blade maintenance

If the saw blade is not used immediately, it should be placed flat or suspended using the inner hole. No other items or footsteps can be stacked on the flat saw blade, and attention should be paid to preventing moisture and rust.When the saw blade is no longer sharp and the cutting surface is rough, it must be re-sharpened in time. Grinding can not change the original angle, and destroy the dynamic level. Correction of the inner diameter of the saw blade, processing of positioning holes, etc., must be carried out by the manufacturer. If the processing is not good, it will affect the use effect of the product and may be dangerous. In principle, the reaming should not not exceed the original diameter of 20mm, so as not to affect the balance of stress.

General Use Tungsten Carbide Tipped TCT Aluminum Cutting Circular Saw Blade

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23