Car Alloy Wheels 15 16 17 18 19 20inch Alloy Top Quality Custom New Design Aluminium Alloy Wheel for Car

Weifang Leying Trading Co., Ltd / 2022-06-24

- Material:Aluminum

- Type:Rim

- Drive Wheel:FWD

- Wheel Hub Diameter:16-20"

- Finishing:Chrome

- Wheel Accessories:Hub Ring

=== Base Info ===

- Model NO.:AW-003

- Spoke Type:Equal Diameter Spoke

- Certification:ISO, CE

- Wheel Hub Brand:Jz

- PCD:100

- Hole:5

- Et:20

- Width:4.5~11 Inch

- Design:Aftermarket and OEM

- Process:Casting

- Size:18*8.0 Inch,19*8.0 Inch

- C.B:54~76 (mm)

- MOQ:100

- Car Make:for Car

- Transport Package:Carton

- Specification:16 inch

- Trademark:JZ

- Origin:China

- HS Code:7604210000

- Production Capacity:10000PCS,Day

=== Description ===

18*8.0

IF YOU WANT TO SEE MORE WHEEL RIMS, PLEASE CLICK THE PHOTOS

Product Introduction:

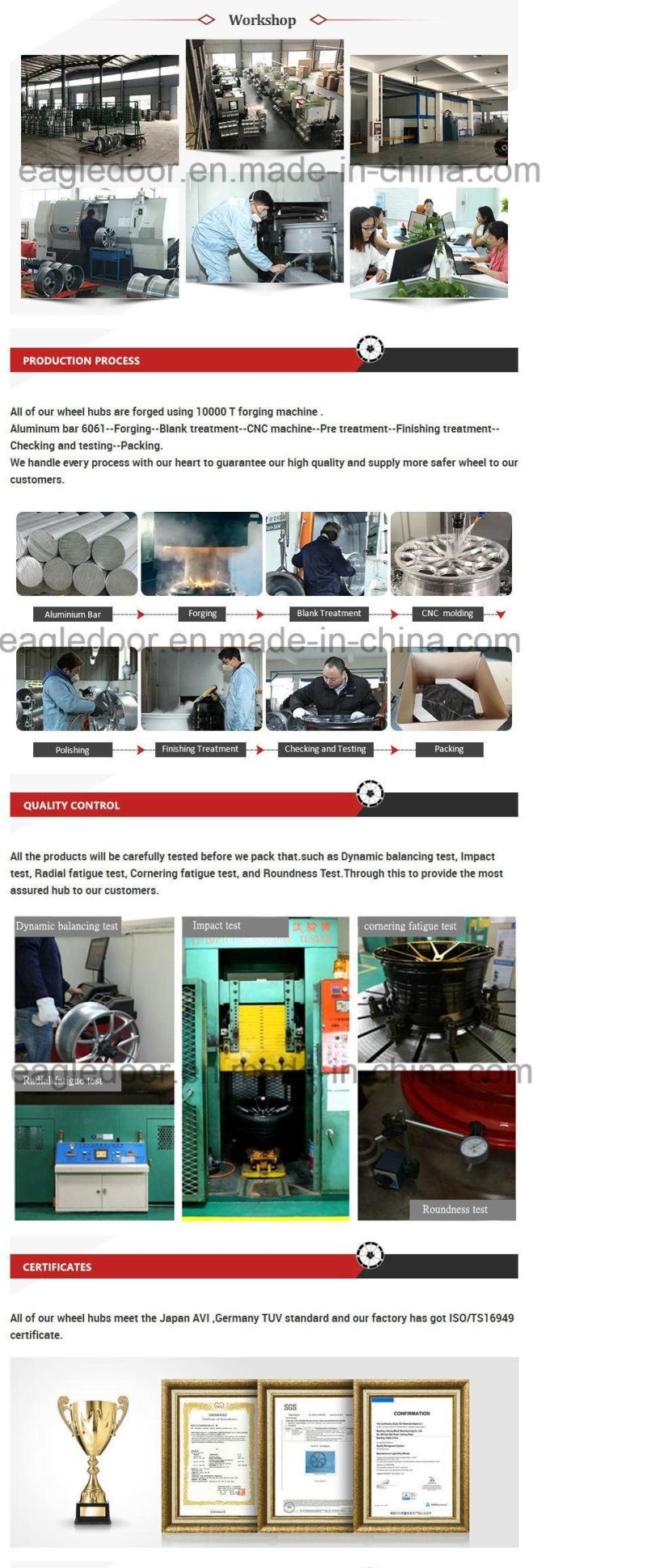

Forcar Aluminum A356.2 Casting & T6 Forged Alloy Wheels from 10inch to 28inch with VIA, JWL, TUV, ISO, DOT certificates;

1. Chemical composition: A356&A356.2 alloy steel(Si 6.5-7.5, Mg 0.30-0.45, Ti<0.2, Fe<0.12 Mn<0.1 Cu<0.05 Zn<0.05 Al)

2. Finishing: Black, silver, gunmetal, matt black, grey, hyper black, hyper silver, machined face, machined lip, color line, chrome, vacuum chrome, anodized, full Polish, milling, sand blast, two colors, etc.

3. Process: Lower pressure, Gravity casting, Forged

4. Quality Guarantee: ISO/TS 16949: 2000quality system, German TUV, America SFI, DOT, Japanese VIA, JWL, ISO 9001: 2008quality system, the national mandatory "C" certification

OEM PROCESS:

1. Design according to customer's sample or photos;

2. Making a new design according to different wheels pattern or concept;

3. Making original design according to customer's sketch or concept drawing;

4. Car Fitment Checking;

5. Strength simulation and optimization before mold development

Wheel Rims Sample or Pictures→Deposits→ Drawings→Mould→Production→Wheel Sample→Testing (strict quality control including X-ray, Air Tightness, Bending, Impact, Blance, CMM, Salt Spray...)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23