Special Timing Belt Pulleys

Guangzhou Shunxu Plastic Packaging Co., Ltd. / 2022-06-27

- Application:Motor, Motorcycle, Machinery, Marine, Agricultural Machinery, Industry

- Hardness:Soft Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Rolling Gear

- Toothed Portion Shape:Spur Gear

- Material:Steel 1045, S45c, C45e

=== Base Info ===

- Model NO.:According to drawing

- Type:Circular Gear

- Black Coated Steel Gear:Black

- Phosphated Cast Iron Gear:Dark Grey

- Manipulate Way:Forced Manipulation

- Changes Way:Mixed

- Transport Package:Blank Carton in Wooden Cases

- Trademark:Ubet Machinery

- Origin:China

- HS Code:8483900000

- Production Capacity:50, 000 Pieces,Month

=== Description ===

Basic Info.

Model NO. According to drawing Type Circular Gear Black Coated Steel Gear Black Phosphated Cast Iron Gear Dark Grey Manipulate Way Forced Manipulation Changes Way Mixed Transport Package Blank Carton in Wooden Cases Trademark Ubet Machinery Origin China HS Code 8483900000 Production Capacity 50, 000 Pieces/MonthProduct Description

Ubet produce types of gears, spur gears are the most commonly used.

Material available in steel and stainless steel

Number of teeth: 10 to 150

Modulus 1 to 5, pressure angle 20°

Advantages of Spur Gear:

- Spur gears have high power transmission efficiency.

- They are compact and easy to install.

- They offer constant velocity ratio.

- Unlike belt drives, spur gear drives have no slip.

- Spur gears are highly reliable.

Applications of Spur Gear:

- Metal cutting machines

- Power plants

- Marine engines

- Mechanical clocks and watches

- Fuel pumps

- Washing Machines

- Gear motors and gear pumps

- Rack and pinion mechanisms

- Material handling equipments

- Steel mills

- Gear boxes

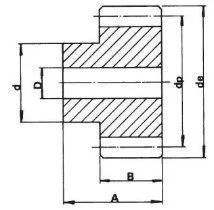

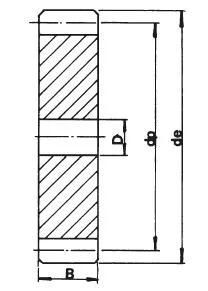

Dimension A as per

Module 1 = 25 mm; Module 1.5 = 30 mm

Module 2 = 35 mm; Module 2.5 = 40 mm

Module 3 = 50 mm; Module 4 = 60 mm

Module 5 = 75 mm; Module 6 = 80 mm

Dimension B as per

Module 1 = 15 mm; Module 1.5 = 17 mm

Module 2 = 20 mm; Module 2.5 = 25 mm

Module 3 = 30 mm; Module 4 = 40 mm

Module 5 = 50 mm; Module 6 = 60 mm

Dimension B as per

Module 1 = 15 mm;

Module 1.5 = 17 mm

Module 2 = 20 mm;

Module 2.5 = 25 mm

Module 3 = 30 mm;

Module 4 = 40 mm

Module 5 = 50 mm;

Module 6 = 60 mm

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23