Slewing Drive Solar Panel Tracking System Solar Energy Tracker

Jinjiang Huawin Chemical Co., Ltd. / 2022-06-27

- Feature:Corrosion-Resistant

- Step:Double-Step

- Openness:Closed

- Installation:Vertical

- Transmission Form:Worm

- Type:Single-Row Ball

=== Base Info ===

- Model NO.:VH8-60S110-RC

- Output Torque:6300n.M

- Output Speed:0.025rpm

- Holding Torque:45kn.M

- Gear Ratio:60:1

- IP:65

- Tilting Moment Torque:10kn.M

- Color:Grey

- Electric Motor:Yes

- Transport Package:Standard Exporting Package

- Specification:VH8-60S110-RC

- Trademark:Coresun Drive

- Origin:Changzhou

- HS Code:8483409000

- Production Capacity:3000PCS,Month

=== Description ===

Model

VH8

IP

IP65

Brand

Coresun Drive

Type

Vertical

Material

42CrMo,50Mn

Output Torque

6.3KN.m

Tilting Moment Torque

10KN.m

Holding Torque

45KN.m

Static Axial Rating

350KN

Static Radial Rating

120KN

Square Tube

Motor

Gear Ratio

60:1

Efficiency

40%

we adhere to "commitment to excellence,continuous improvement,customer's satisfaction"quality concept.Our managerment is in strict accordance with ISO 9001 management system.We aim to always meet our customers'need through our continuous improvement.

Our slewing drive is powered with hourglass worm technology for maximum gear torque and the smoothest rotation. Typical slew drive applications include solar industry, truck cranes, man lifts, and utility equipment, hydraulic attachments, oil tool equipment, marine cranes, tire handlers, digger derricks and automotive lifts, but the slew drives are used in many other applications requiring load holding and rotational capability. We offer different slew drive models with different moment load capacities. The standard slew drives are fitted with an open housing and single self-locking hourglass worm shaft. Once the power source input is returned to neutral, the worm shaft will lock the load into position without requiring any external braking device.

The slew drive can be with worm gear, spur gear, bevel gear. And also for the inside slewing ring, it can be single-row ball slewing ring, and also can be double-row ball slewing ring. The one with double-row can take much more load. It can be chosen depended on your application.

Worm gear slewing drives are the most cost-effective and optimum solutions for single axis PV trackers. They are designed, tested, and guaranteed for accuracy and performance for a 30-year field life time.

Compared with fixed PV trackers which could produce the highest levels of energy only when the sun is at the optimum angle to the panel, the PV trackers could be directly towards the sun from sunrise to sunset.

1. Special design based on different applications and projects

2. Different types of motors could be matched, such as hydraulic motors, stepper motors, electrical motors etc.

3. Different colors are available based on RAL code; our standard color is RAL 9006.

4. Connection of a driving motor from the left or right side

5. During installation, it is not necessary to adjust the gearing clearance; this is already set by the producer before factory

6. Simple installation and low maintenance

7. Rational space utilization

8. The gear is self-locking; therefore a brake is not necessary

9. Easy and fluent method of starting and stopping

Products Application

Coresun Drive slewing drive VH8 is a good solution to 60-96pcs single axis solar tracker design.

The production is widely export to USA,Canada,Germany,Spain,France,Poland,Turkey,Korea,Australia,South Africa,India, Brazil,Chile...

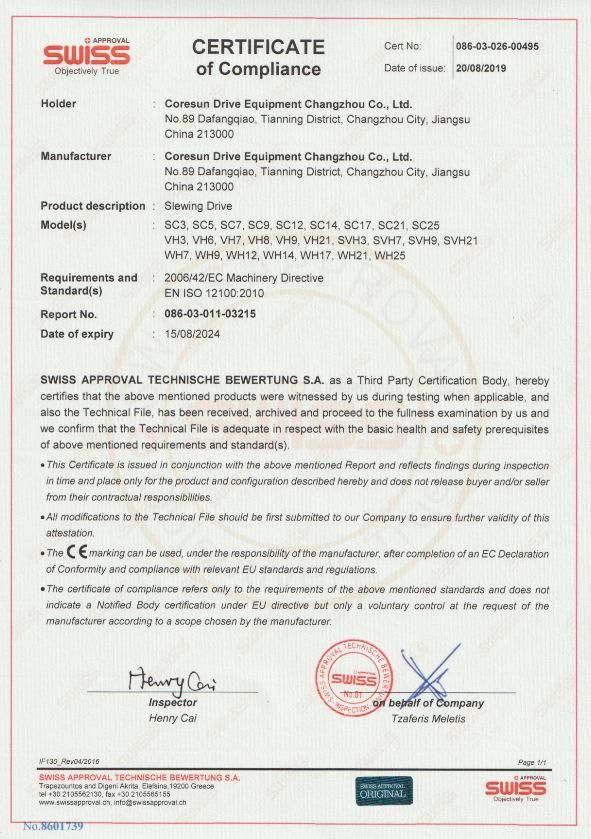

Products Certificate

Our slewing drive gear motor have arroved by CE and ISO2001 certificate.

CONTACT US

It is sincerely looking forward to cooperating with you for and providing you the best quality product & service with all of our heart!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23