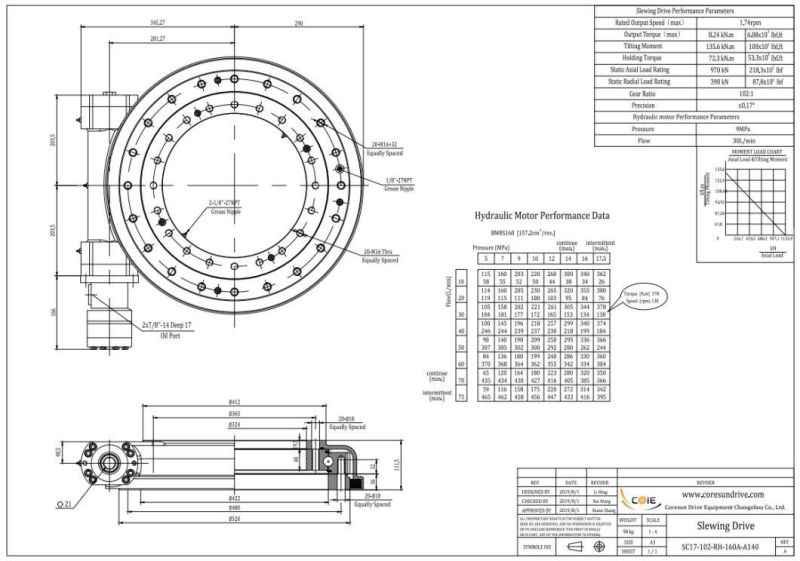

Sc17 Slewing Drive for Rotation Equipment

Jinjiang Huawin Chemical Co., Ltd. / 2022-06-27

- Holding Torque:72.3kn.M

- Tilting Moment Torque:135.6kn.M

- Output Torque:12.24kn.M

- Output Speed:1.47rpm

- Gear Ratio:102:1

- IP Class:IP65

=== Base Info ===

- Model NO.:SC17-102-25RH-160A-REV. A

- Static Axial Load:970kn

- Static Radial Laod:390kn

- Color:Grey

- Transport Package:Wooden Case

- Specification:SC17-102-25RH-160A-REV. A

- Trademark:Coresun Drive

- Origin:Changzhou

- HS Code:8483409000

- Production Capacity:5000PCS,Month

=== Description ===

Coreun Drive slewing drive products are high-quality slewing drive products developed with independent technology and technology to meet market needs. Coresun Drive has a full range of mature slewing drive products with multiple specifications and the ability to custom design and manufacture such products for customer needs. For different applications requiring low-speed heavy loads, high-speed medium loads and high-speed light loads, Khanwang can provide corresponding products or solutions.

Coresun Drive's worm-gear slewing drive includes two categories: cylindrical worms and envelope worms. Cylindrical worms are suitable for medium-speed and heavy-duty applications, and envelope worms are suitable for low-speed, heavy-duty and high-precision applications. The worm-gear slewing drive is self-locking , In the field of power sports, it can provide basic safety guarantee and further simplify the overall design of the equipment. It is a superior industrial accessory.

This increased tooth engagement results in greater strength, efficiency and durability.The slewing drive uses standard worm technology in which the worm on the horizontal The speed ratio of the shaft depends on the relationship between the number of threads on the worm and the number of teeth in the worm gear or gear.The specifications of the drive and gear depend on the material of the gear. However, most of the drives and gears typically used consist of steel and phosphor bronze. According to a wide range of tests,chilled nickel-phosphorus bronze ranks first in terms of Wear resistance and deformability.

The slewing drive is a new type of slewing product, usually called slewing ring, which is usually composed of worm, slewing ring, housing, motor and other components. Since the core components are slewing bearings, they can simultaneously withstand axial forces, radial forces, and overturning moments. Compared with traditional rotary products, the new rotary drive features easy installation, easy maintenance and a greater degree of installation space.

Rotary drive slewing drive worm gear is a perfect combination of turbine worm products, worm ring surface envelope form, its tooth contact area is large, so the transmission torque is large, stable operation.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems (QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Coresun Drive Slewing Bearing Production Photo and Application

Coresun Drive Relevant Certification as following

CONTACT US

It is sincerely looking forward to cooperating with you for and providing you the best quality product & service with all of our heart!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23