High Quality Precision Grinding Helical Gears

Heavybao Commercial Kitchenware Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Printing

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Bevel Wheel

- Material:Aluminumtiming

=== Base Info ===

- Model NO.:precision grinding gear

- Type:Bevel Gear

- Transport Package:Outer Carton

- Specification:0.8

- Trademark:iHF

- Origin:China

- HS Code:84839000

- Production Capacity:30000,Month

=== Description ===

Basic Info.

Model NO. precision grinding gear Type Bevel Gear Transport Package Outer Carton Specification 0.8 Trademark iHF Origin China HS Code 84839000 Production Capacity 30000/MonthProduct Description

2019 year High quality helical gearsOur company is established 22 years, High quality, very famous in China, the top 3 in the industry.

Main products: synchronous pulleys, Gears, reducers. Over 500 employees.

Advantages

1.Good quality products

2.Competitive prices

3.Fast delivery

4.Best after-sale service

5.Brand: HeFa or OEM & ODM

6.Materials Available: Stainless Steel, Carbon steel, Brass, Bronze, Iron, Aluminum Alloy

7.Bore: Finished Bore, Pilot Bore, Special request

8.Processing method: Molding, shaving, hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc.

9.Pressure Angle: 20 Degree

10.Hardness: 80 HV

11.Size: Customer Drawings & ISO standard

12.Package: Wooden Case/Container and pallet, or made-to-order

13.Certificate: ISO9001:2008

14.Lead Time: Within 35 days after get your payment.

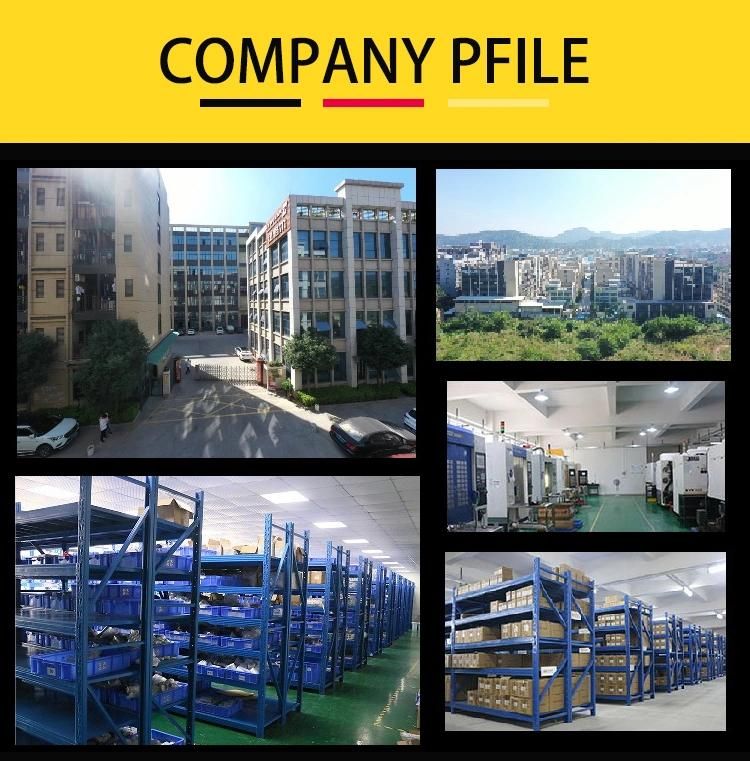

Our company:

Hefa group was born in Shenzhen in 1998. It is a transmission component manufacturer committed to pursuing precision and speed. Hefa group adheres to the German precision planetary transmission design and manufacturing technology, and has more than 20 years of experience in the field of gear manufacturing. It is equipped with processing equipment such as LAISENHAUER gear grinding machine of Switzerland, CNC gear shaper of Mitsubishi Heavy Industry of Japan, CNC helical gear broaching machine of NACHI, hard tooth surface hobbing machine of Hamai and Qinchuan gear grinding machine. At the same time, it is also equipped with a series of precision gear testing equipment such as TTI gear tester of Japan, universal gear measuring instrument of Harbin quantity group and HEXAGON three coordinates, It has strong manufacturing ability and detection control ability, and can quickly provide professional solutions for customers in different fields.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23