Casting Truck Brake Pad 29ad1369 29ad1370 with Hardware Kits

Condon Trading(Shanghai) Co., Ltd. / 2022-06-24

- After-sales Service:18 Months From Purchasing

- Warranty:80, 000-90, 000 Kilometers

- Type:Brake Pads

- Material:Semi-Metal

- Position:Front

- Certification:ISO,TS16949, ISO9001, DOT, ECE

=== Base Info ===

- Model NO.:29AD1369 29AD1370

- Classification:Disc

- Drum Brakes Classification:Brake Pad

- Main Market:Mild East

- Width:247.6 mm

- Height:54.7mm

- Length:146mm

- Thickness:19.8mm

- Certified:Ts16949, Eac, E-MARK

- Transport Package:Neutral Packing or at Buyer′s Request

- Specification:CE, SGS, ISO, TS16949

- Trademark:Pujie

- Origin:Qingdao, China

- HS Code:87083095

- Production Capacity:10, 000 Sets,Month

=== Description ===

Basic Info.

Model NO. 29AD1369 29AD1370 Classification Disc Drum Brakes Classification Brake Pad Main Market Mild East Width 247.6 mm Height 54.7mm Length 146mm Thickness 19.8mm Certified Ts16949, Eac, E-MARK Transport Package Neutral Packing or at Buyer′s Request Specification CE, SGS, ISO, TS16949 Trademark Pujie Origin Qingdao, China HS Code 87083095 Production Capacity 10, 000 Sets/MonthProduct Description

1. Features :Benefits of Galvanized Steel

- Corrosion resistance superior to powder coating

- Longer product life: Galvanized steel will outlast the friction material

- Fit and function is improved, reduced returns, noise benefits

- Premium product that matches OE

- Visually appealing

- Ensures optimal performance over time

- No possibility of damage

- Perfect for harsh environments like braking

- The zinc coating forms its own oxide coating over time, further protecting steel from corrosion

- Environmentally friendly, 100% recyclable

2.The Role of Backing Plates in Brake Pads

our car's braking system is composed of various mechanical parts that work in tandem to bring your vehicle to a halt. Ultimately, friction material presses against the rotor of your wheel and your car stops. This friction material is attached to a steel part known as a backing plate. Friction material and steel backing plates are attached in one of two ways, either through adhesives which can breakdown or through mechanical attachment such as PUJIE™.

The harsh braking climate can lead to brake pad failure as a result of separation between friction material and the backing plate. This can result from adhesive breakdown which leads to a complete separation between friction material and braking plate. Inferior steel can also lead to brake pad failure, highlighting the importance of using steel which is either pickled and oiled or galvanized.

Equally important to attachment, backing plates should fit and function within the brake caliper. PUJIE backing plates meet this requirement.

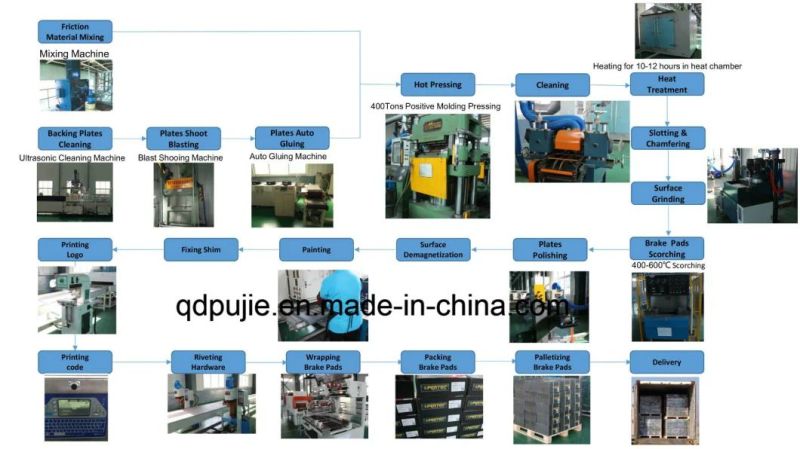

3. Factory show :

PUJIE air disc brake pads are formulated for typical line haul service and can be used on vehicles in combination with 20,000-lb or 23,000-lb rated drum brake materials.

The back plates are blanked from a high grade of hot-rolled, pickled and oiled steel to resist corrosion.

The pad retention system is the long-time proven mechanical attachment method of wire mesh welded to the steel back plate combined with a special, high strength under layer to insure a secure bond for the life of the pad.

The friction material itself is integrally molded to the under layer.

The "FS" formulation has a long history of use in Europe and has been ECE R-90 performance certified.

This material offers consistent service and good wear characteristics.

Each axle set of disc brake pads comes packaged with the hardware needed to complete a first class brake job.

CROSS REFERENCE:

D1369/ 8479-D1369/ Mercedes Benz # 004 420 70 20/ MMD1369AF/ MPBD1369CV/ MPBD1369XT/ 802078/ K054101/ K070796/ S291522/ 03057008500/ BXK070796/ 29158/ 141.D1369FS SAF # 3057008500/ EMD1369AF

Bendix 802078 Air Disc Brake Kit

- Application BENDIX CALIPER APPLICATION ADB22XSB6000 CALIPER FMSI NUMBER 8479-D1369

- Series BENDIX CALIPER APPLICATION ADB22XSB6000 CALIPER FMSI NUMBER 8479-D1369

- Air Disk Brake Kit for Bendix Caliper

- 4 802078 Pad Assemblies, Dayco tagged Hardware Kit:

- 7 springs, 2 pins, 2 washers, 2 split pind, 1 hexagonal adapter, 2 rubber caps

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23