Sintered Iron Oil Retaining Cylindrical Bearing

Wenzhou Conlene Bags Co., Ltd. / 2022-06-08

- Bearing Structure:Solid Bearing

- Type of Lubricant:Oil-Lubricated Bearing

- Lubricant & Load:Hydrodynamic Bearing

- Bushing Material:Oil-Impregnated Bearing

- Bearing Direction:Radial

- Lubricating Way:Maintenance-Free Bearing

=== Base Info ===

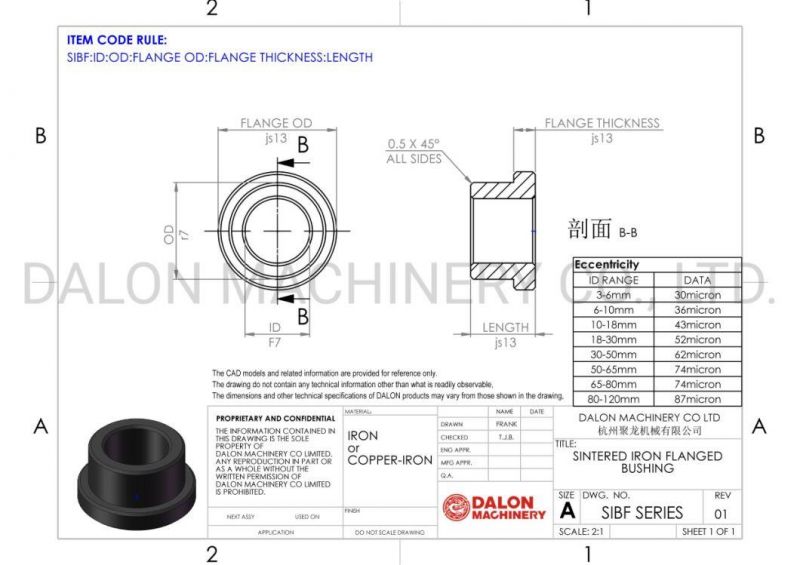

- Model NO.:SIB

- Lubricating Film Thickness:Thin Film Lubrication

- Certification:ISO9001:2015

- Bearing Type:Plain , Spherical

- Tolerance Range:F7r7 Js13 , DIN1494

- for Load Direction:Radial, Thrust, Combined Radial & Thrust

- Shaft Mount Type:Press Fit

- Lubrication:Lubricated

- Material:Cusn663 or SAE841

- Transport Package:Carton , Pallet

- Specification:05mm ~ 150mm

- Trademark:DALON

- Origin:Zhejiang, China

- HS Code:8483300090

- Production Capacity:50tons Monthly

=== Description ===

HB

HB

Standard material specifications include: SAE 841, ASTMB 438 Grade 1 Type II,

CuSn 6-6-3, Sint B 50 & Standard impregnating oil conforms to SAE 30 specifications

Sintered Bronze and iron based self-lubricating bushings are made of two different functions:

The metallic alloy structure which supports and transfers the mechanical loads

The oil lubricant or graphite contents which separates two surfaces in relative motion and to reduce friction.

DALON BUSHING ADVANTAGE:

With no moving parts, sintered bronze bushings are the simplest type of bearing. Compared to ball and roller bearings, they generally handle higher temperatures and perform better in dirty environments. They are also intended by design to be self-lubricating, maintenance free and low cost.

DALON BUSHING APPLICATIONS:

DALON Sintered bronze bushing are recommended for following movements:

- Rotation

- Oscillation

- Linear

- Higher speeds requirement

- Higher loads requirement

- General assembly machinery, industrial vehicles, automation, farm machinery, sewing machines,

- bottling machines, key duplicating machines, electrical switchgears, mobility, toys, etc.

- Washing machines, fans, woodworking machines, vacuum cleaners, extractor fans.

- coffee machines, juicers, rotisseries, hand tools, air conditioning, boilers, etc.

- Lawnmowers, roller shutters, office swivel chairs, locks, garage doors, awnings, sliding windows,

- hinges, furniture, gardening, etc.

DALON BUSHING FAQ:

Q: Bushing type selection?

A: The metallic structure of the self-lubricating bushing can be made from a wide range of bronze or iron based alloys. To select the proper material for a given application, it is necessary to check the maximum values of the material characteristics in comparison with:

- Shaft linear speed - v

- Applied load - p

- pv (load x speed) factor

temperature and type of lubrication, etc.

Q: Lubricant Oil Selection?

A: Standard impregnating oil conforms to SAE 30 specifications

Lubricants are suitable for the temperature range from -40°C to 150°C

Also have option for customer to made special oil impregnation by self

Q: De-impregnation & Re-Impregnation?

A: De-impregnation required Degrease and wash in appropriate solvent

Eliminate the lubricant in a furnace heated around 400°C for 40 minutes under a neutral atmosphere such as N2, or with reducing agent such as N2 + H2

Re-Impregnation need Immerge during one hour the parts in an oil bath heated at a temperature between 60°C and 120°C, depending on oil viscosity .Then cool down in an oil bath back to room temperature. Finally drain and dry the self-lubricating bearings.

Q: Factory or Trading Company?

A: DALON established in 2002 and have two factories under DALON group with shareholders, one workshop specialized in sintered bronze bushing and another handles all sintered filter and silencers.

Q: What is MOQ?

A: We are enjoying to grow up together with all of our clients whatever big or small orders. You will become bigger and bigger to be with DALON.

Q: Can DALON make customized products?

A: Yes, DALON can offer OEM / ODM manufacturing

Q: Will drawing or sample design safe after DALON get it?

A: DALON will NOT release your design to any third parties without your permission. Usually we will sign NDA before all drawing and samples.

Q: Can DALON offer design services?

A: DALON have R&D and can offer special design about your requirements with drawing 3D in format IGES/STEP,PDF/ CAD in DGW/DXF & photos.

Q: How about Quality System?

A: DALON have ISO9002 quality system and in-house inspection by Projector, CMM, Hardness Tester, Roughness Tester, Salt Spray Tester, Tensile Strength Test, Caliper, Micrometer, Height Gauge, Ring and Plug Gauge, Pin Gauge ,etc.

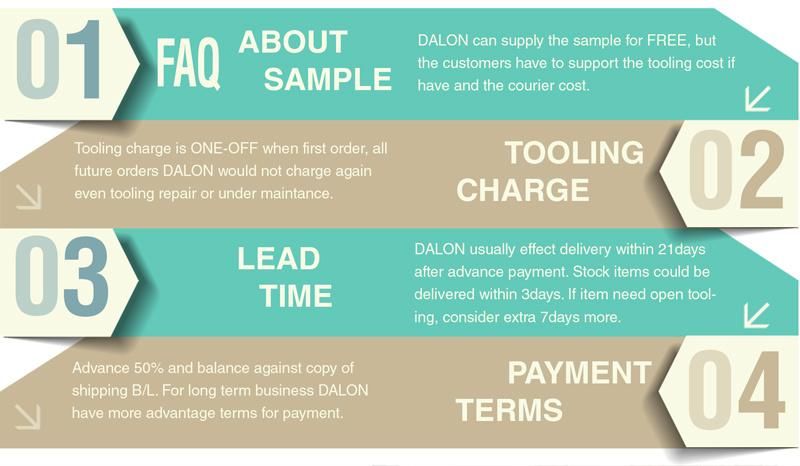

Q: About Sample?

A: DALON can supply the samples for FREE, but the customers have to support the tooling cost if have and the courier cost

Q: Tooling Charge?

A: Tooling charge is one off when first order, all future orders would not charge again even tooling repair or under maintaince.

Q: Lead Time?

A: DALON usually effect delivery within 21days after advance payment. Stock items could be delivered within 3days. If item need open tooling, consider extra 7days.

Q: Payment Terms?

A: Advance 50% and balance against copy of shipping B/L. For long term business DALON have more advantage terms for payment.

Q: How to deal with the complains if happens?

A: In any case of complains, please contact DALON within 30days after receive the goods, DALON will find the root causes and corrective & preventive actions. DALON will take full responsibility for the claims.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23