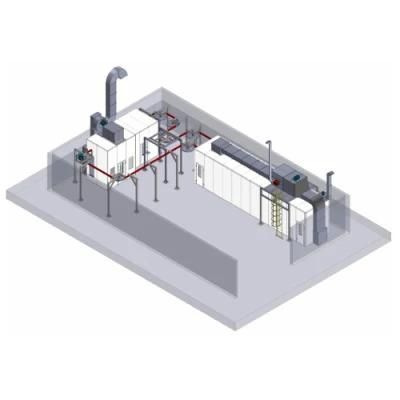

Infitech Customized Spray Booth with Automatic Conveyor Chain

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Fully Undershot-type

- Heating Mode:Gas

=== Base Info ===

- Model NO.:Customized

- Paint Mist Treatment:Wet-type

- Condition:New

- Transport Package:Polyfoam and Metal Frame

- Specification:12000 X 2500 X 3150mm (L X WX H)

- Trademark:INFITECH

- Origin:China

- HS Code:8419899090

- Production Capacity:300 Sets Per Year

=== Description ===

BS EN 60204: 2006 + A1: 2009

BS EN 60204: 2006 + A1: 2009

BS EN 60204: 2006 + A1: 2009

Item D: Automatic conveyor chain

Product details

- Water-curtain booth

- Driving system of the conveyor chain

Conveyor chain

Parts of the conveyor chain

Why choose INFITECH?

1. Quality Control

We carry out strict quality control to ensure product quality, from supplier selection, incoming inspection, in-process inspection to pre-delivery inspection.

We listen to what our customers say and always look for ways to improve our product quality through continuous improvement.

2. ODM & OEM Ability

We can provide ODM & OEM services. We especially pride ourselves in project design and customized spray booth projects.

3. Parts Availability

We use international standard electric components and consumables.

And we keep stock of spare parts and make sure they are available whenever you need.

4. Good Warranty

Customer satisfaction and product quality are our first priority. We offer 2-year warranty for main components and attentive after-sales service.

FAQ

1 Q: Are you manufacturer or trading company?

A: We are professional manufacturer, with abundant experience in providing pre-sales technical support, project design, product manufacturing, installation & maintenance guidance and after-sales service. With INFITECH, you can always have reliable consultative approaches whenever you need.

2. Q: Can you put my brand name (logo) on these products?

A: Yes. We have experience and capabilities to professionally tailor to your individual needs.

3: What certificates do you have?

A: We've got CE certificate for our spray booth product.

4. Q: What is your product quality?

A: We carry out strict quality control, from supplier selection, incoming inspection, in-process inspection to final inspection before ex-work.

We carefully examine every aspect of every order from design and layout, production, packing to delivery.

5. Q: What is your warranty?

A: Our warranty is 24 months after commissioning. We attend to every request/query from the user during the installation, commissioning, operation and maintenance processes. Warranty is for main components. Consumables are not included in warranty.

6. Q: What is the delivery time?

A: For standard products, the production lead time is 25 days after receiving the advance payment.

For customized products, we will need to check according to the specific condition.

7. Q: How to install and maintain the spray booths?

A: Our spray booths are designed for easy installation and maintenance. We will provide you with detailed installation manual/operation manual/maintenance manual.

Installation/commissioning guidance is also available.

8. Q: What about the availability of the electric components and consumables?

A: We use international standard electric components and consumables. Meanwhile, we keep stock of spare parts and make sure they are available whenever you need.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23