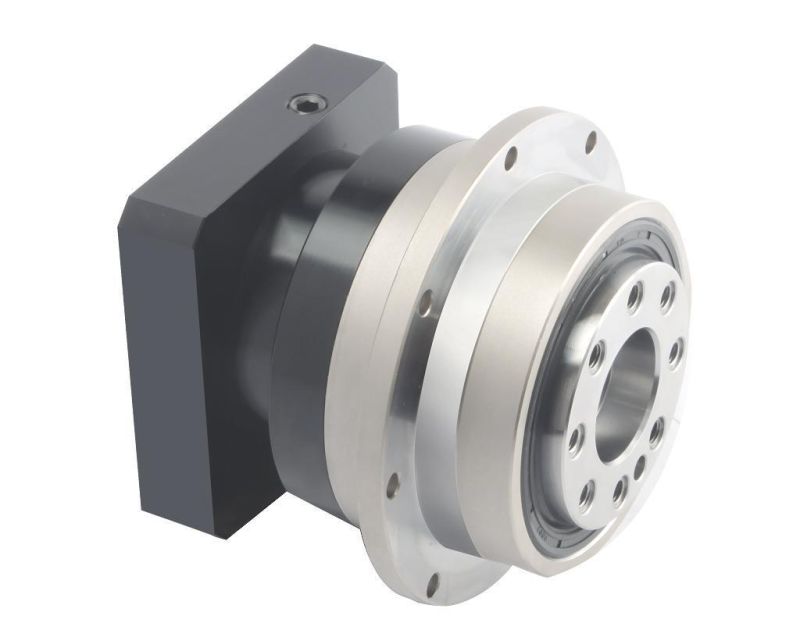

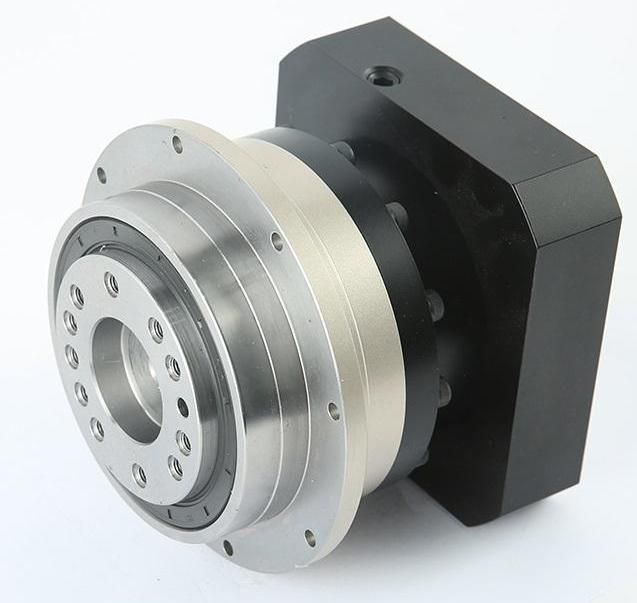

Ad Series Servo Helical Teeth Planetary Gearbox

Ningbo Yinzhou Guda Imp. & Exp. Co., Ltd. / 2022-06-27

- Application:Machinery

- Function:Speed Changing, Speed Reduction

- Layout:Planetary

- Hardness:Hardened Tooth Surface

- Installation:Vertical Type

- Step:Single-Step

=== Base Info ===

- Model NO.:AD gearbox

- Type:Planetary Gear Box

- Application Filed:CNC Machine

- Transport Package:Wooden Cases or Cartons

- Specification:AD-

- Trademark:SHK

- Origin:China

- HS Code:8483409000

- Production Capacity:1000000

=== Description ===

Type

Rated output torque

(Nm)

emergency stop torque

Rotational inertia

(kgm2)

(arcmin)

(Nm/arcmin)

Stages

High precision

Backlash less than 3 arc minutes, accurate positioning

High rigidity and high torque

The use of integral deep groove ball bearings greatly improves rigidity and torque

Strong compatibility

Connector and bushing mode can be installed on any private servomotor

No leakage of lubricating grease

Use high-viscosity, non-separable grease to effectively prevent grease leakage

Easy maintenance

In the life of the product, no need to replace the grease installation, more convenient

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23