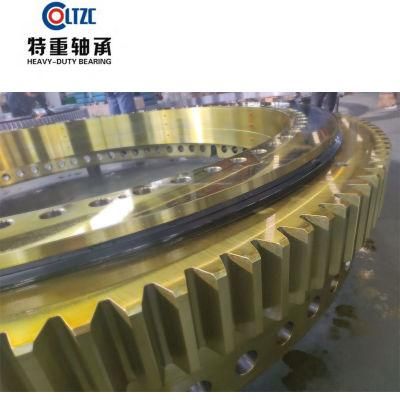

Cross Cylindrical Roller Slewing Bearing with Outer Tooth, External Gear

Shantou Weixin Industrial Co., Ltd. / 2022-06-08

- Standard or Nonstandard:Nonstandard

- Feature:Corrosion-Resistant

- Sealing Gland:Sealed On Both Sides

- Rolling-Element Number:Single-Row

- Roller Type:Crowned Raceway

- Material:Bearing Steel

=== Base Info ===

- Model NO.:E1797,664

- Type:External Gear

- Transport Package:Plywood Case

- Specification:664x858x75mm

- Trademark:LTZC

- Origin:Luoyang

- HS Code:8483900090

- Production Capacity:10000 Sets,Year

=== Description ===

Dimension

Type

Weight

d

D

T

mm

kg≈

1100

1390

91

111.28.1250.03/P5

352

1260

1540

96

111.32.1400.03K/G1

428

1400

1728

110

D1792/1400

624

1466

80

111.28.1600.03

405

1466

80

111.28.1600.03

405

1460

1740

91

111.32.1600.03K

486

1629

100

111.36.1800.03

690

1954

148

1797/1954

1116

1954

148

1797/1954K

1135

1825

2132

112

111.40.2000.11K/P5

838

1825

2178

112

111.40.2000.12K

862

1825

2178

112

111.40.2000.03K

862

1825

2178

135

111.40.2000.03K1/P5

1110

2100

2600

180

1797/2100G2K3

2377

2327

119

1797/2327

1322

2460

3016

220

1797/2460

3794

2500

210

1797/2500K3

4597

2500

210

1797/2500K12

4597

2500

210

1797/2500K13

4596

2325

2678

112

112.40.2500.12

1147

2325

2678

112

112.40.2500.03

1147

2579

3021

231

1797/2579

3118

2600

200

1797/2600G2K7

3558

2600

200

1797/2600G2K8

3558

2600

200

1797/2600K

3562

2350

2820

220

111.65.2610.12

2989

2635

3332

270

1797/2635G2K

5925

2635

3400

270

1797/2635GK

5936

2625

2978

112

111.40.2800.03K

1282

2625

2978

112

112.40.2800.03

1298

2625

3192

150

112.40.2800.03K

2780

2610

2990

134

111.50.2800.03

1652

2922

3376

134

111.50.3150.12K1

2165

2922

3376

134

111.50.3150.03K

2179

2922

3376

134

112.50.3150.03

2161

2868

3432

270

111.90.3150.03

4943

2930

3470

225

112.80.3200.03K

4493

3322

3776

134

111.52.3550.03

2493

3322

3776

150

112.50.3550.12K2

2484

3322

180

112.50.3550.12K3/G1

3389

3760

4450

250

1797/3760

8246

3820

164

111.40.4030.03

3106

3830

180

111.50.4030.03K

3552

4272

4726

174

112.50.4500.12K1

4302

4272

4690

174

112.50.4500.12K2

4444

3230

3990

240

1797/3230K6

8096

3230

240

1797/3230K7

7669

3230

3970

240

1797/3230K8

7613

3230

3970

240

1797/3230K9

7627

3230

3970

252

1797/3230K10

7859

3230

240

1797/3232K11

7663

3230

3970

240

1797/3230K12

7613

3230

3990

240

1797/3230K13

7712

3230

3970

240

1797/3230K14

7613

3230

3970

240

1797/3230K15

7613

3230

3970

240

1797/3230G2K14

7613

3230

3990

240

1797/3230G2K15

8096

3230

3970

240

1797/3230G2K16

7613

3230

3960

240

1797/3230G2K17

7633

3230

3970

240

1797/3230G2K18

7619

3230

3970

240

1797/3230G2K19

7619

3230

3970

240

1797/3230G2K20

7613

3230

240

1797/3230G2Y5

7673

3230

3970

240

1797/3230G2Y6

7613

3230

240

1797/3230G2Y7

7673

620

61

111.20.7100.03/P6

82.2

674

853

70

111.25.770.03K/P4

101

674

853

70

111.25.770.03K1/P4

101

810

125

E1797/810

420

854

1136

100

D1797/856

298

954

1234

124

1797/954

455

888

1041

83

111.25.980.03

129

168

254

21

C1797/168

5.31

171

40

D1797/171

14.3

200

315

30

1797/200

15

235

380

55

1797/235K

24.5

200

322

35

111.12.260.03

11.2

200

322

35

111.12.260.03/P5

11.2

250

372

35

111.12.310.03/P5

13.4

260

86

111.30.386.03

87

496

694

65

D1797/496

79.7

472

694

60

111.25.587.03/P5

83.7

664

858

75

E1797/664

109

FAQ

Lubrication Performance Requirement

Lubrication selections are mainly according to loading, temperature, vibration and working environment etc. Additional considerations should also be taken into account:

Good performance on high and low temperature range, preferably waterproof.

Operating temperature should be 20ºC higher than the bearing working temperature.

Good performance in extreme pressure situations, in addition to antiwear properties.

Where bearings adopted a centralized lubrication system, then it is important to ensure consistency within the system, so as to maintain a smooth flow of lubricant at any time.

Commonly used grease for slewing bearings included Calcium based grease, Lithium based grease, and Aluminum based grease etc.

Lubrication Period

The slewing bearing's lubrication intervals are dependent on the working condition and environment in addition to the run time. Some recommendations are detailed below:

Generally lubrication maintenance should be performed every 150 hours. If under extreme working conditions then this period should be reduced to 50~100 hours. (Typical extreme conditions are high moisture conditions,high temperature,dusty environment, etc)

If the bearing is scheduled to be out of service for a long period of time, then the bearing needs to be filled with lubricant.

Lubrication Methods

Grease should be injected from the respective lubrication holes (the greasing points are generally a screwed hole with the size of M10×1 plug). After greasing slowly turn the bearing so as to ensure that the grease is distributed evenly.

If there are no special greasing requests then grease should be inserted within the bearing until grease leaks out from the sealing lip in an even manner.

The lubricating hole can be used as the intake point or the extract point. When re-lubricating the old grease should be purged out by new grease that is being injected.

After re-lubrication ensure that lubrication plug is placed back into the grease point. (For individual lubrication point)

Hot Tags: cross cylindrical roller slewing bearing with outer tooth, manufacturers, wholesale, customized, high quality, low price

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23