Modern Outdoor Sunny Chaise Lounge

Winstar Co., Ltd. / 2022-06-24

- Style:Modern

- Material:Metal

- Color:Black

- Type:Single

- Disassembly:Disassembly

- Certification:ISO9001

=== Base Info ===

- Model NO.:HG-537

- Customized:Customized

- Condition:New

- Surface:Polishing, Painting

- Process:Die Casting

- Size:Customized

- Brand Name:Hzhiger

- Model No.:Hg-427

- Place of Origin:Zhejiang, China

- Dimensions:Customized

- Application:Outdoor Furniture

- Certificate:ISO9001

- Folded:Unfolded

- Transport Package:Foam Bag+Carton or According to Customers

- Specification:ISO9001

- Trademark:hzhiger

- Origin:Zhejiang, Hangzhou, China

- Production Capacity:1000 Sets Per Month

=== Description ===

Basic Info.

Model NO. HG-537 Customized Customized Condition New Surface Polishing, Painting Process Die Casting Size Customized Brand Name Hzhiger Model No. Hg-427 Place of Origin Zhejiang, China Dimensions Customized Application Outdoor Furniture Certificate ISO9001 Folded Unfolded Transport Package Foam Bag+Carton or According to Customers Specification ISO9001 Trademark hzhiger Origin Zhejiang, Hangzhou, China Production Capacity 1000 Sets Per MonthProduct Description

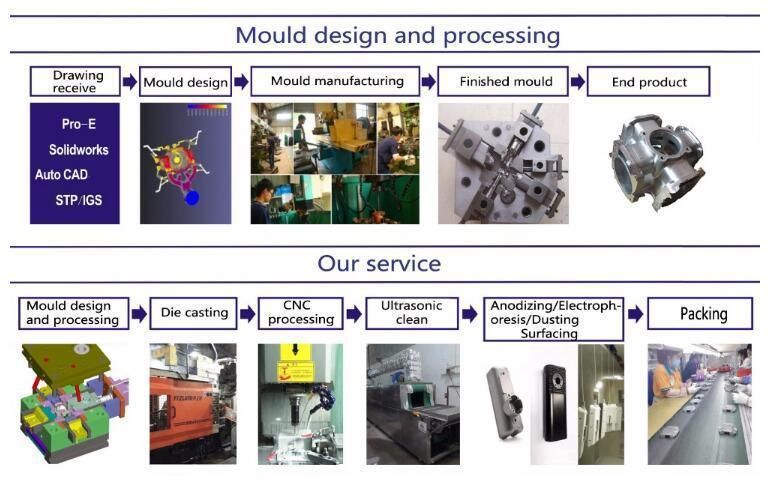

PROCESS

Workshop:

Business Range:

parts range: aluminum alloy parts:(A380,ADC12,ADC10,6061,Etc......)

Zinc alloy parts:(ZAMAK3, ZAMAK5 Etc......)

Brass alloy parts:(Si9Cu3, Cuzn-37 Etc......)

Iron parts: (Nodularc Iron, Ductile Iron Etc......)

Etc......

Production Process:

Die casting

Sand casting

Gravity casting

Stamping casting

Extrusion profile

Pressing casting

CNC

Etc......

Finishing: E-coated, Powder coated, Anodizing, Painting, Etc......

Product Character:

-Customized Tool Design Drawings are Available;

-Molds are carefully machined to the closest tolerance using the latest equipment;

-The prototype should be created if the customer require;

-We offer secondary processing such as oil spraying, screen printing, assembly ect.

-Traceability is maintained from all inspection gages

-Mold repair and maintenance are also supported internally.

Advantage:

1.more than 20years experience in casting and machining

2.one-stop service,from mould design,casting,machining to surface treatment

3.abundant technology force, good condition of production and inspection,

and perfect after-sales service.

4:ISO9001,SGS,TS16949 certificate

5:have own quality laboratory,offer CMM inspection,leaking

test,Spectroscope raw material test.

6:rich experience in exporting,export products to more than 50 countries

Application:

Machinery, Electrical, Agriculture, Building, Medical,Etc......

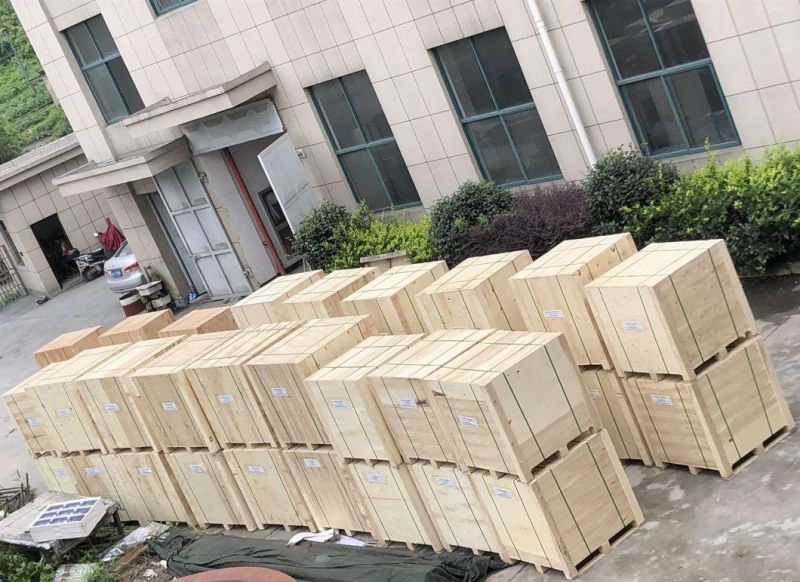

Package and Shipping:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23