Manufacturer OEM Zinc Alloy Die Casting Gears

Hangzhou Baixin Imp. &Exp. Co., Ltd / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Toothed Portion Shape:Double Helical Gear

- Material:Zinc

- Type:Circular Gear

=== Base Info ===

- Part Material:Zinc Alloy

- Mold Cavities:1

- Die Casting Machine Type:88 Ton Hot Chamber Die Casting Machine

- Part Weight:85g

- Tolerance Grade:8

- Lead Time for Mold:6 Weeks

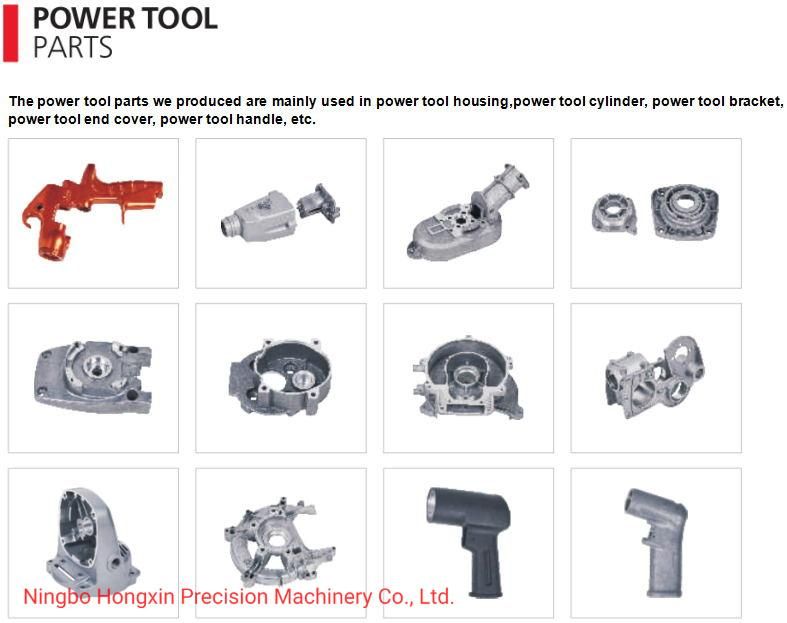

- Applications:Power Tools

- Transport Package:PP Bag or Bubble Bag and Carton and Pallet

- Origin:Ningbo City, China

- HS Code:8473500000

- Production Capacity:2000000 PCS Per Year

=== Description ===

Overview

Company Profile

Product DescriptionOur Advantages

Samples

FAQ

FAQ | Q1. Where is your company? |

| A:Our company is located in Ningbo City, Zhejiang province, which is known as the hometown of mold |

| Q2. Are you a factory or trading company? |

| A: We are a direct and professional factory and specialized in die casting industry since 2011. |

| Q3.Can your company make by sample? |

| A: Yes, we can make by both the sample and drawing. |

| Q4. What do I need to provide if I want to customize products and get a offer? |

| A: You can send 2D & 3D drawing(.step/.stp/.igs/.dwg is prefer) or samples and detailed requirement to our team. |

| Q5. What's the process of Customizing product? |

| A: 1. Design of product drawings/samples. 2. Confirm the drawing with the customer. 3. Make the mold. 4. Send sample to customer for approval. 5. Receive confirmation from customer and series production. 6. Quality inspection 7. Packing and shipping. |

| Q6. Can your company make the mold? |

| A: Yes, design mold and make mold and fixture by ourselves. |

| Q7. Your company's yearly production capacity? |

| A: 200 set of molds, 5 Million die casting parts and aluminum extrusion parts, 1 Million plastic injection parts |

| Q8. What is the minimum order quantity? |

| A:No MOQ for aluminum CNC parts. Low MOQ can be provided to help you test market. |

| Q9. How long is the lead time? |

| A: Depends on the order quantity. 1 week for prototypes,Normally 3-7 weeks for mold, 2-4 weeks for series production parts. |

| Q10. How do you package the products? |

| A: Bubble bag - Carton Box - Wooden pallet. Special packaging method can be accepted. |

| Q11. What is the payment method? |

| A: T/T, WEST UNION, PAYPAL. |

| Q12.How is the quality? |

| A: Strict control before shipment. |

| Q13: What if I got some defective products? |

| A:If you find any defective products, we will exchange good products or refund you immediately. If you have any questions, please feel free to contact us. |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23