High Efficiency Spray and Bake Cabin for Bus Refinishing

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

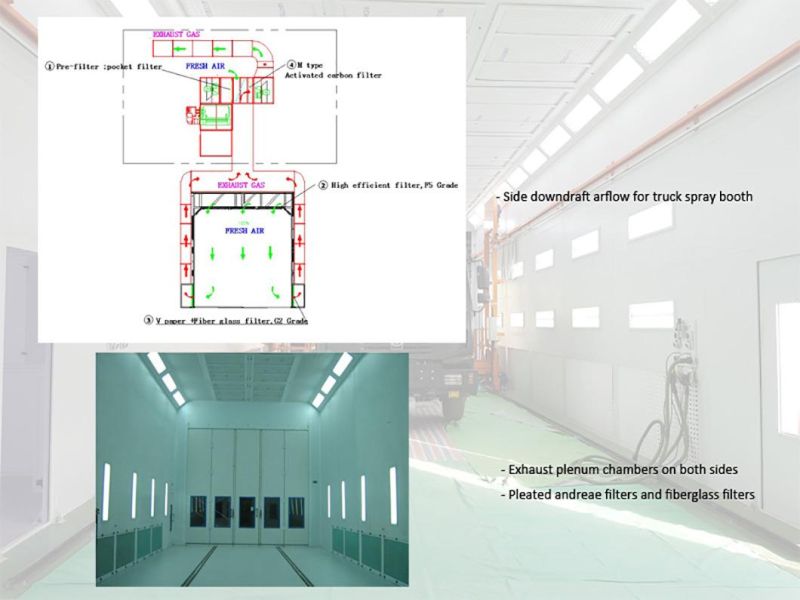

- Airflow Direction:Side Downdraft

- Heating Mode:Diesel

=== Base Info ===

- Model NO.:IT-15-5B

- Paint Mist Treatment:Dry-type

- Condition:New

- Airflow:Side Downdraft

- Plenum (Height):800mm

- Extraction Area:21.6m2

- Walls:60mm Rock Wool Walls

- Brightness:>1,000lux

- Air Volume:2*35,000m3,H

- Empty Loaded Air Speed:0.26m,S

- Heats:Riello Diesel Burner Rg5d*2

- Maximum Working:80 Celsius

- Controls:CE Standard

- Inverter:Schneider

- Stack Light:Yes

- Rated Power:50kw

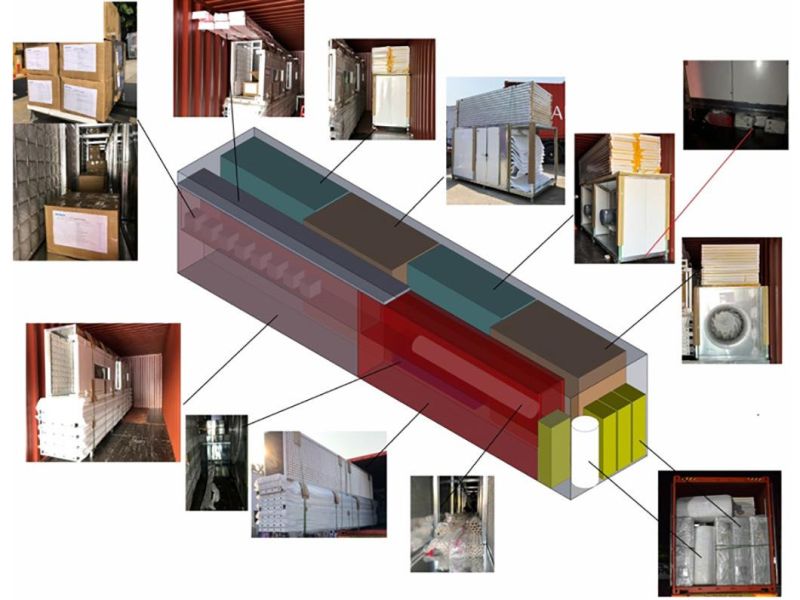

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:15000 X 5000 X 5000mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Model NO. IT-15-5B Paint Mist Treatment Dry-type Condition New Airflow Side Downdraft Plenum (Height) 800mm Extraction Area 21.6m2 Walls 60mm Rock Wool Walls Brightness >1,000lux Air Volume 2*35,000m3/H Empty Loaded Air Speed 0.26m/S Heats Riello Diesel Burner Rg5d*2 Maximum Working 80 Celsius Controls CE Standard Inverter Schneider Stack Light Yes Rated Power 50kw Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 15000 X 5000 X 5000mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

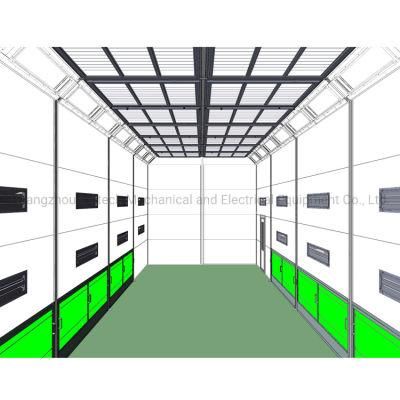

High Efficiency Spray and Bake Cabin for Bus Refinishing1.FEATURES

The truck spray booth IT-15-5B comes with side downdraft airflow. The air is extracted through both sides exhaust plenum chambers, requiring no floor excavation.

The airflow volume is 70,000m3/h by 2 groups of 2*11 direct drive air handling units.

Its robust booth structure, premium airflow and lighting, high efficiency air handling units and easy-to-use control makes the spray booth ideal solution and maximize profits for shop owners.

The spray booth not only can be used for trucks and buses painting and drying, but also suits industrial manufacturing applications, such as furniture, heavy machinery etc.

The booth dimensions and configurations can be customized to meet your special needs.

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | IT-15-5B Side Downdraft Truck Spray Booth |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

| Internal dimensions | 15000 X 5000 X 5000mm (L X W X H) |

| External dimensions | 15170 X 8320 X 5800mm (L X W X H) |

| Airflow | Side Downdraft |

| Plenum (height) | 800mm |

| Extraction | Exhaust plenum chambers on both sides of the booth |

| Extraction area | 21.6m2 |

| Entrance door | 4270x4800mm (WxH), 1 set |

| Service door | 800x2000mm(WxH), 4 sets |

| Walls | 60mm rock wool walls |

| Ceiling lights (LED) | 20 sets, each 4 X 18W, 1,440W total |

| Sidewall lights (LED) | 18 sets, each 4 X 18W, 1,296W total |

| Brightness | >1,000LUX |

| Filters | Bag filter, high efficiency ceiling filter, filter at exhaust plenum chambers, exhaust filter |

| Intake/Exhaust unit | Direct-type turbine fan, 2* 2x11KW, SIEMENS motor |

| Air volume | 2*35,000m3/h |

| Empty loaded air speed | 0.26m/s |

| Heats | 2*232kw heat exchanger, RIELLO diesel burner RG5D*2 |

| Maximum working temperature | 80ºC |

| Controls | CE standard control box |

| Inverter | SCHNEIDER inverter |

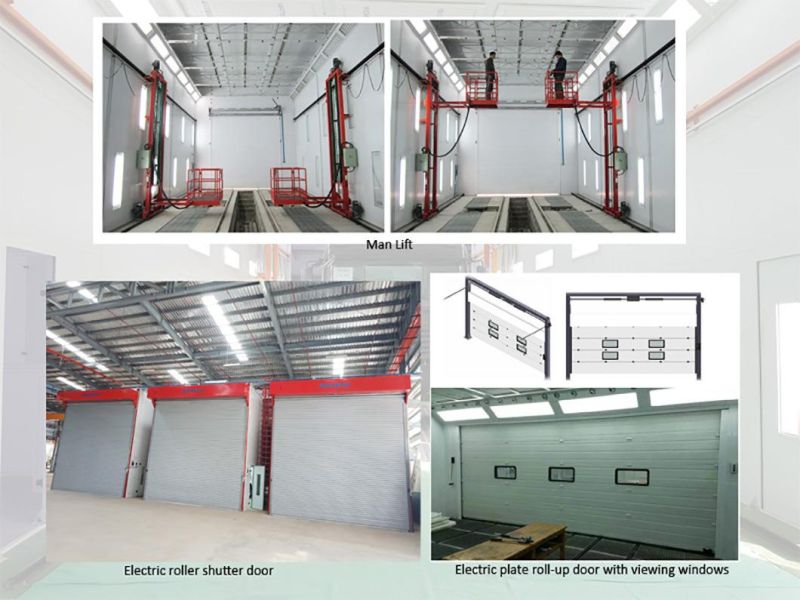

| Option | Man lift; Touch screen control; Electric entrance door |

| Rated power | 50KW |

3.DETAILS

AIRFLOW

IT-15-5B truck spray booth comes standard with side downdraft airflow.

The fresh air is drawn in by the intake fan. It passes though the heat unit, and then enters the top plenum, where there is diffuser, adding as the cushion to reduce the airflow speed. The air flows to the plenum through small holes of the diffuser. With the air well distributed inside the plenum, the airflow from the plenum to the workspace can be consistent, which is import for achieving good quality refinish and exhausting the overspray. After that, the waste air is extracted through exhaust plenum chambers on both sides of the spray booth.

OPTION

For the truck spray booth, other types of overspray treatment methods are provided to meet different installation fields' requirements.

- Downdraft with pit and grids in the ground for extraction

- Rear semi downdraft airflow

REINFORCED BOOTH STRUCURE

Truck spray booth is big size spray booth, the structure of which must be solid and robust enough. Infitech truck spray booth comes with reinforcement gantry structure (made of square tubes) to ensure the overall strength. Please see the illustration in the photo below.

MAIN ENTRY DOOR

- Manual entrance door with anti-falling device

LIGHTS

- Angled ceiling and horizontal sidewall lights, brightness over 1,000lux

OPTION

- Electric entry door

- Explosion-proof lighting fixtures

- Front and back ceiling lights

AIR MAKEUP UNIT

- 2 sets of 2*11kw generator units, 70,000m3/h air volume

- Direct-drive fan units, with non-spark design fan

OPTION

- Gas burner

- Direct gas fired heating system

- Electric heating

- Air makeup unit on the side or at the top of the spray booth

CONTROL

- Control comes standard with manual buttons

- SCHNEIDER inverter

- Spraying, heating spraying, flash, baking, cooling

- Overheat alarm, failure alarm, fan and heating system interlock control etc.

UPGRADE

- Innovative digital screen control

FILTERS

| Item | Specification |

| Pre-filter | Bag filter |

| Ceiling filter | High efficiency F5 grade filter |

| Floor filter | Pleated andreae filters + Fiberglass paint arrestor filter |

| Extract filter | Activated carbon filter |

OPTIONS

- Pneumatic man lift

- Electric roller shutter door

- Electric plate roll-up door

PACKAGING AND LOADING PHOTOS

The cargo of the spray booth is packed and loaded on metal frames to be handled by forklifts, saving time and improving efficiency in the loading and unloading process.

FAQQ: How to install the truck spray booth?A: Regarding the installation, you do not need to worry about it. For all delivered spray booths, customers are always provided detailed installation instructions (including installation steps, installation drawings, wiring diagram, packing list, installation tools etc) to help guide the installation and wiring. Meanwhile, Infitech sales engineer will follow up closely the installation process to ensure that the installation proceeds correctly and find out problems and get them solved in time.

Q: How long does it take for the whole installation and commissioning process?A: For the truck spray booth, it takes about 1 month to get it assembled and commissioned.

Q: How many people do I need for the installation, wiring and commissioning?A: For the truck spray booth, it is recommended to get it installed by 5-6 people, including 1 professional electrician.

Q: Can I install the truck spray booth outdoors?A: It is okay, but the truck spray booth must be protected by a shed from rain and snow.

Q: I want to add a manual door in-between to divide the booth into two parts. So when I spray and bake smaller vehicles, I can use one half of the truck spray boot. Is this possible?A: Certainly. We have done similar projects before. We can add manual door or electric door as divider in the booth. And we can allow separate control for each part of the booth. Please consult one of our experts for more details.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23