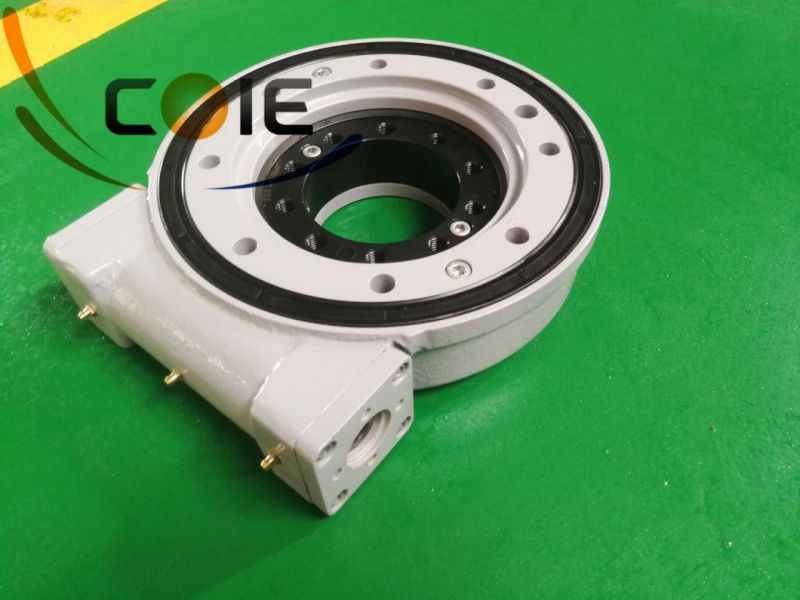

Heavy Load Hydraulic Motor Slewing Drive Turntable Bearing

Jinjiang Huawin Chemical Co., Ltd. / 2022-06-27

- Feature:Corrosion-Resistant

- Holding Torque:10.4kn.M

- Tilting Moment Torque:13.5kn.M

- Output Torque:2kn.M

- Output Speed:1rpm

- Gear Ratio:71:1

=== Base Info ===

- Model NO.:SC7-71-RH

- IP Class:IP65

- Static Axial Load:133kn.M

- Static Radial Laod:53 Kn.M

- Precision:0.15

- Mechanical Efficiency:40%

- Specification:SC7-71-RH

- Trademark:Coresun Drive

- Origin:Changzhou

- HS Code:8483409000

- Production Capacity:3000PCS,Month

=== Description ===

Model

SC7

Place of Origin

Changzhou,China

Brand

Coresun Drive

Delivery Time

7 days

Material

42CrMo,50Mn

Output Torque

1.46kN.m

Tilting Moment Torque

13.5kN.m

Holding Torque

10.4kN.m

Static Axial Rating

133KN

Static Radial Rating

53KN

Dynamic Axial Rating

32KN

Dynamic Radial Rating

28 KN

Gear Ratio

71:1

Efficiency

40%

Hydraulic Motor

Yes

HS Code

8483409000

Coreun Drive slewing drive products are high-quality slewing drive products developed with independent technology and technology to meet market needs. Coresun Drive has a full range of mature slewing drive products with multiple specifications and the ability to customize design and manufacture such products for customer needs. For different applications requiring low-speed heavy loads, high-speed medium loads and high-speed light loads, Khanwang can provide corresponding products or solutions.

1. The Size, Direction And Nature Of The Load: the slewing drive is suitable for bearing light load, and the roller bearing is suitable for bearing heavy load and impact load.When the rolling bearing is subjected to pure axial load, thrust bearing is generally selected.When the rolling bearing is subjected to pure radial load, deep groove ball bearing or short cylindrical roller bearing are generally selected.Deep groove ball bearing, angular contact ball bearing, tapered roller bearing and self-aligning ball or self-aligning roller bearing can be used when the rotary device is subjected to pure radial load and small axial load at the same time.When the axial load is large, the angular contact ball bearing and tapered roller bearing with large contact Angle can be selected, or the radial bearing and thrust bearing can be combined together, which is especially suitable for high axial load or special requirements of large axial rigidity.

2. Allowable Speed: the type of slewing bearing drive varies greatly.Under normal circumstances, low friction, less heat bearing, suitable for high speed.The design should make every effort to work under the condition that the rotary rolling bearing is lower than its speed.

3. Rigidity: When the bearing of the rotary driving device bears load, elastic deformation will occur at the contact point between the bearing ring and the rolling body. The deformation is proportional to the load, and the ratio determines the rigidity of the bearing.Generally, bearing rigidity can be improved by pretightening the bearing.In addition, the bearing stiffness can be improved by considering the combination and arrangement of the bearing in the bearing design.

4. Centering Performance And Mounting: After the bearing is loaded into the working position, the mounting and positioning are often poor due to manufacturing error.This is often due to shaft fishing and thermal expansion and other reasons, so that the bearing bear too much load, causing early damage.The self-aligning bearing can overcome the defects caused by the installation error, so it is suitable for this kind of bearing.

5. Installation And Disassembly Of Rotary Driving Device: tapered roller bearing, needle roller bearing and tapered roller bearing, etc., belong to the type of bearing with detachable inner and outer rings (the so-called detachable bearing), which is convenient for installation and disassembly.

Coresun Drive slewing drive SC7 worm shaft,casting housing and slewing bearing machining.

CONTACT US

It is sincerely looking forward to cooperating with you for and providing you the best quality product & service with all of our heart!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23