Magnetic Clamping System Quick Mold Change

Zhongshan Artigifts Premium Metal & Plastic Co., Ltd. / 2022-06-09

- Certification:CE

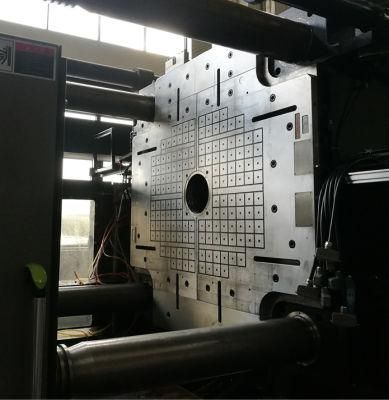

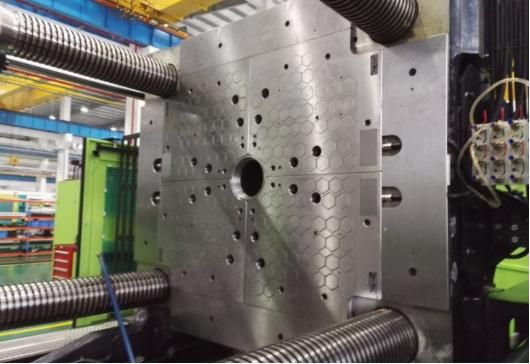

- Application:Injection Molding Machine

- Power:Electric

- Structure:Solid

- Material:Stainless Steel

- Type:Magnetic Chuck

=== Base Info ===

- Package of Magnetic Chucks:Carton, Wood Case

- Application of Magnetic Chucks:Injection Molding Machine

- Efficient:Quick Mold Change in 3 Minutes

- Transportation:by Sea, by Express, by Air

- Lead Time:7-25 Days

- Transport Package:Carton, Wood Case

- Specification:Customized

- Trademark:GME magnetic chucks

- Origin:Xiamen

- HS Code:8505909090

- Production Capacity:100sets

=== Description ===

Basic Info.

Package of Magnetic Chucks Carton, Wood Case Application of Magnetic Chucks Injection Molding Machine Efficient Quick Mold Change in 3 Minutes Transportation by Sea, by Express, by Air Lead Time 7-25 Days Transport Package Carton, Wood Case Specification Customized Trademark GME magnetic chucks Origin Xiamen HS Code 8505909090 Production Capacity 100setsProduct Description

Description

Magnetic Clamping System for Quick Mold Change is applied to the injection molding machine, die casting machine, punching machine, and turning machine through magnetic plate compatible with mold changer to achieve safe, fast, and convenient replacement for large molds, to accomplish the effect of quick mold change.

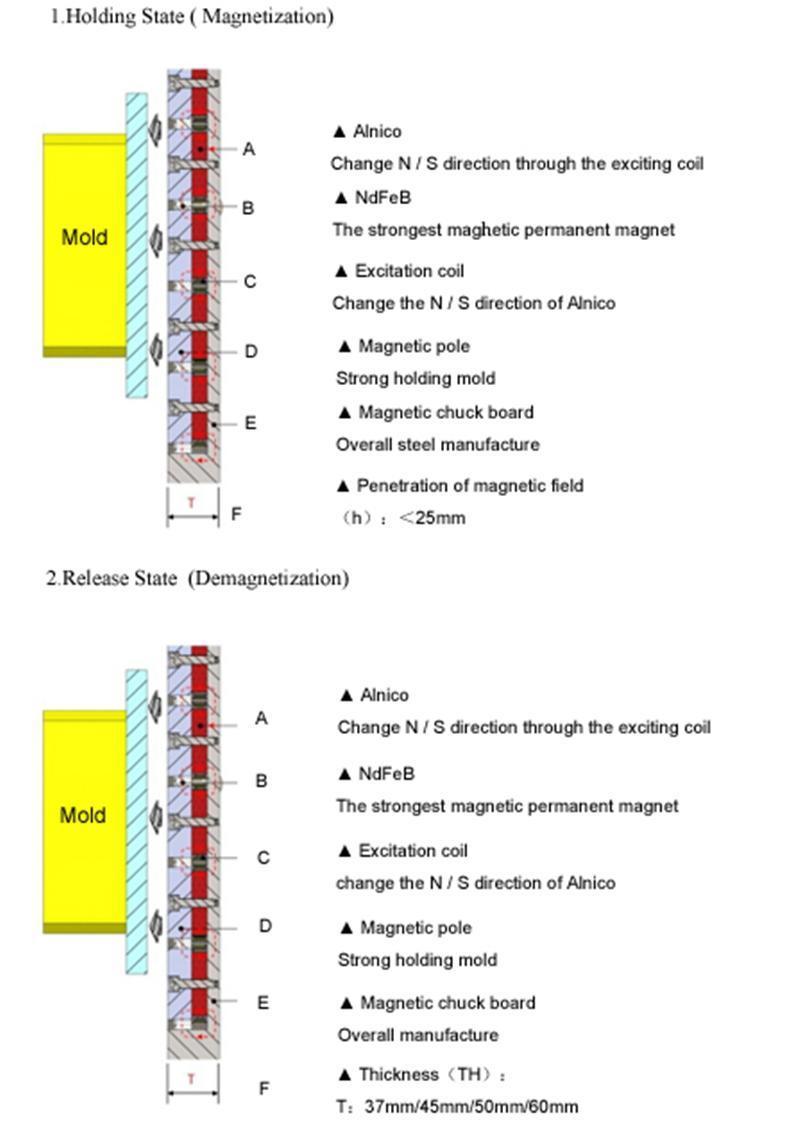

The magnetic clamping system is used to fix the mold on the injection machine. Magnetic plate is designed for the traditional injection machine and gives a solution for long working time on change molds, complex operation, and low security. This system uses a permanent magnet sucker as a fixed plate and moving plate, just by simple actions of magnetization and demagnetization, will fix & change the mold, which can indeed change mold in 3 minutes. The injection molding machine with a magnetic plate improved mold change time to 3 minutes but without changing the original structure, it is practical and convenient.

Features of Magnetic Clamping System for Quick Mold Change

With this magnetic clamping system, users are receiving unparalleled advantages including:

• standardized molds are not required

• height of clamping edge and mold shape is not necessary

• shorter downtimes, lower setup costs

• increased productivity

• clamping in barely accessible positions without any problems

• no reduced clamping surfaces

• process monitoring and thus absolute safety

• clamping force on the complete surface of the mold

• clamping with no deformation of the base plate

• reduced maintenance costs

Electro-Permanent Magnet Principle

Company Information

Great Magtech Electric offers an excellent selection of magnetic assembly, magnetic tools, and magnetic equipment for home use, office use, industrial use, computer use, and so on. Both our office and factory are located in Ningbo which is a very developed city and very big seaport.

We provide you with an extensive range of magnetic assembly, magnetic tools, and magnetic equipment. Containing our excellent original design, every product is elaborately produced by our factory. When you use them, you feel so comfortable and wonderful.

We appreciate your inquiry and we will give you incomparably good products and services. Welcome to be our distributor. The high quality of our products and the considerate after-sale service will make your business more and more prosperous.

If you want to purchase magnetic assembly, magnetic tools, and magnetic equipment, please feel free to contact us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23