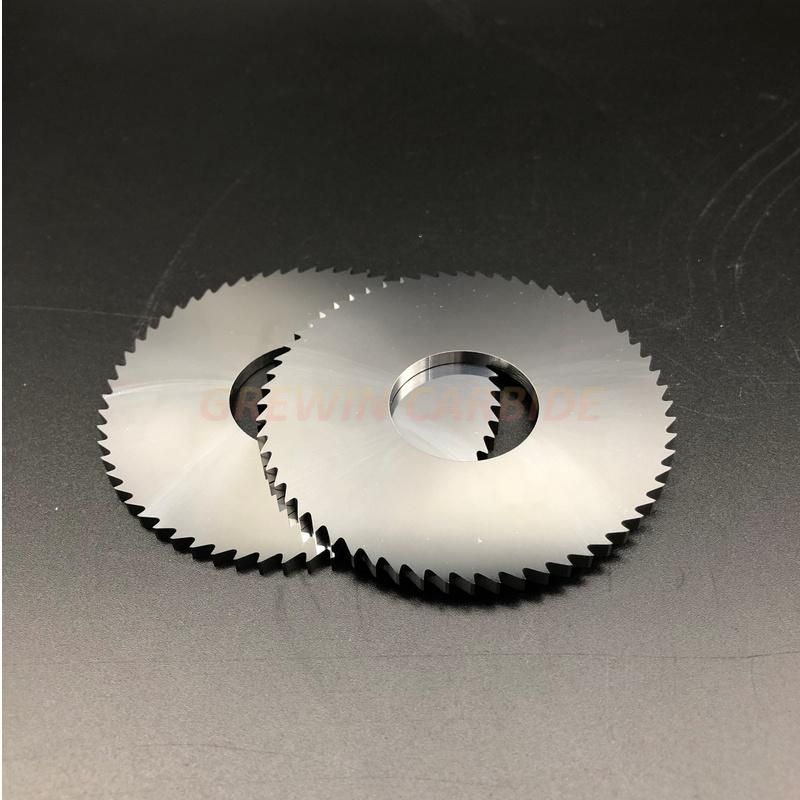

Gw Carbide - Tungsten Carbide Slitting Saw Blade for Metal

Herbalism Science Technology Co., Ltd. / 2022-06-09

- Certification:ISO9001:2008

- Tooth Form:Alternate Tooth

- Diameter:110mm

- Function:Cutting

- Shape:Hole Saw Blade

- Coating:Uncoated

=== Base Info ===

- Model NO.:All sizes

- Type:Carbide Saw Blade

- Materails:Tungsten Carbide

- Co:8%

- Wc:90%

- Grain Size:Ultra Fine

- Thickness:From 0.3mm

- Model Number:Tungsten Carbide Slitting Saw Blade

- Application:Cast Iron;Steel;Stainless Steel;Non-Ferrous Mental

- Technology:Hip Sintered

- Teeth:Accoding to Customer′s Design

- Surface:Polished

- Performance:Compressive Resistance,Bending Resistance

- Standard:ISO

- Packing:Plastic Package Inside, Paper Carton Outside

- Transport Package:Plastic Box Inside and Carton Outside

- Specification:from 30mm to 300mm in diameter

- Origin:China

- HS Code:8207709000

- Production Capacity:30000PCS,Month

=== Description ===

Basic Info.

Model NO. All sizes Type Carbide Saw Blade Materails Tungsten Carbide Co 8% Wc 90% Grain Size Ultra Fine Thickness From 0.3mm Model Number Tungsten Carbide Slitting Saw Blade Application Cast Iron;Steel;Stainless Steel;Non-Ferrous Mental Technology Hip Sintered Teeth Accoding to Customer′s Design Surface Polished Performance Compressive Resistance/Bending Resistance Standard ISO Packing Plastic Package Inside, Paper Carton Outside Transport Package Plastic Box Inside and Carton Outside Specification from 30mm to 300mm in diameter Origin China HS Code 8207709000 Production Capacity 30000PCS/MonthProduct Description

tungsten carbide saw disc with teeth and key way in total tungstenc carbide materialsGeneral information of Carbide disc/tungsten carbide slitting saw blade for mental working with competitive price

The main composition of tungsten carbide saw disc is tungsten carbide powders

and cobalt powders or Nickel powders. With its wear resistant and corrosion resistant ability,

tungsten carbide nowadays is widely used in many areas such as: cutting tools, moulds,

oil and automobile industry.

Tungsten carbide slitting saw blade is used for cutting metal alloys, steel, stainless steel, cast iron, MDF, etc. It can give much more excellent performance than HSS.

With HIP sintering and Nano grain size powders, we can achieve the hardness around 95 HRA.

We have 20 years of experience in producing the tungsten carbide saw blade and

have gained a wide reputation in the market . Welcome your inquiry anytime.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23