High Level Pillow Block Bearing with Advanced Equipments

U&Me Pack Co., Ltd. / 2022-06-08

- Rolling Body:Roller Bearings

- The Number of Rows:Single

- Material:Bearing Steel

- Spherical:Aligning Bearings

- Separated:Separated

- Bearing Material:Chrome Steel(Gcr15)

=== Base Info ===

- Housing Material:Cast Iron(Ht200)

- Hardness:60-63

- Quality Certification:ISO9001: 2008, GB , T 19001-2008

- Design:Standard Design

- Coordination of Bearing & Housing:H7 & J7 & K7

- Steel Ball:G10

- Transport Package:Single Boxed

- Specification:chrome steel

- Trademark:FKD

- Origin:Made in China

- HS Code:84832000

- Production Capacity:20000PCS,Day

=== Description ===

Basic Info.

Housing Material Cast Iron(Ht200) Hardness 60-63 Quality Certification ISO9001: 2008, GB / T 19001-2008 Design Standard Design Coordination of Bearing & Housing H7 & J7 & K7 Steel Ball G10 Transport Package Single Boxed Specification chrome steel Trademark FKD Origin Made in China HS Code 84832000 Production Capacity 20000PCS/DayProduct Description

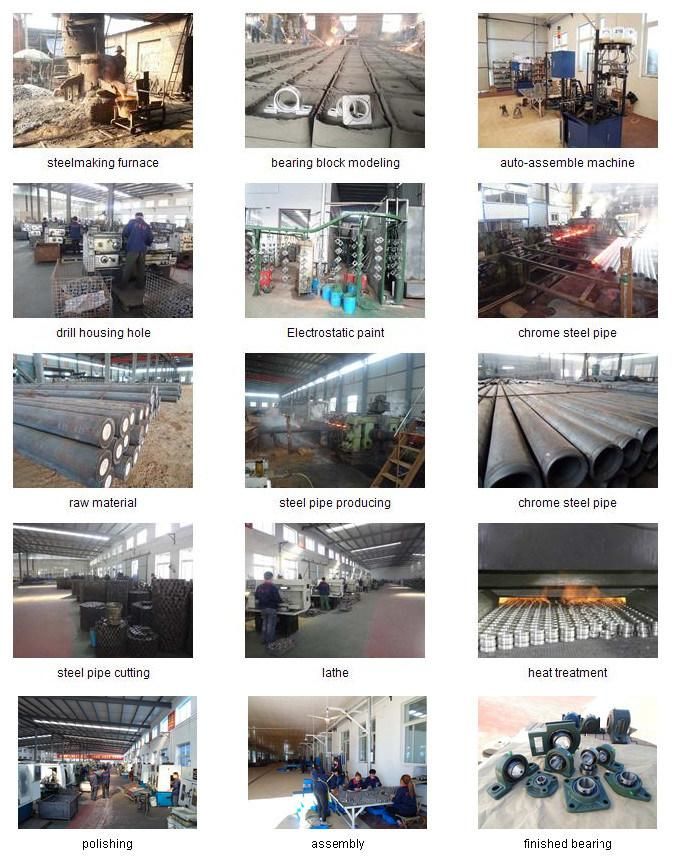

Factory profile

(1)Hebei Hailan Bearing Manufacture Co., ltd, is the professional manufacture and exporter of Pillow block bearing, make the bearing and housing all by ourselves.

(2)30 years' expeience of producing and exporting all kinds of bearings.

(3)With the advanced technique and equipments, we can provide high-level products under standard process and device .

(4)We have passed the ISO9001:2000 International Quality Management System and got the Certificate of Import & Export from our government .

(5)The annual output is more than 10 million sets

Advantage:

(1) We are bearing manufacturers,provide you with all kinds of ball and roller bearings

(2) 30 years' export experience

(3) Competitive prices

(4) Free sample

(5) High quality and high precision

(6) Good service(OEM ,Modle design)

Specification

| Brand | FKD HHB or OEM |

| Structure | Pillow Block Bearing |

| Model Number | Any |

| Bearing Material | Chrome Steel, Stainless Steel, Plastic |

| Cage Material | Copper , Iron |

| Seals | Normal Seal, Triple Seal , F seal or as requirement |

| Lubrication | Grease, Oil |

| Precision | ABEC-1 (P0) |

| Clearance | C1, C2, C0, C3, C4, C5 |

| Vibration | V1, V2, V3, V4 |

| Noise | Z1, Z2, Z3, Z4 |

| Service | OEM |

| Place of Original | Hebei, China(Mainland) |

| Sample | Free Sample |

| Port | QINGDAO or as requirement |

Product Description:

Pillow blocks consist of the insert ball bearing and housing.

Insert ball bearing are designed in almost the same way as deep groove ball

bearing, except the outer ring is spherical and the inner ring is wide.

Application:

Agricultural machinery, construction equipment, conveyor systems, textile machines and mining machines etc.

Bearing Characteristics :

| 1 | These bearings have a compact design and are easy to mount and dismount |

| 2 | With certain self-aligning effect |

| 3 | Large load capacity |

| 4 | Long service life |

| 5 | Low friction; low vibration and low noise |

The variety of the bearings we supply in long term:

| 1 | Pillow Block (Bearing Housing); |

| 2 | Deep Groove Ball Bearings; |

| 3 | Tapered Roller Bearings; |

| 4 | Thrust Ball Bearings; |

| 5 | Agriculture bearing |

| 6 | Self-aligning Ball Bearings; |

| 7 | Angular Contact Ball Bearings; |

| 8 | Insert Bearings (Spherical Outer Surface Ball Bearings); |

Trade Term

| Packaging : | 1. Commercial Packaging: Plastic Bag + Color box + Carton + Pallet; 2. Industrial Packaging 3. According to Customer's Requirements. |

| Delivery: | 2 days for products in stock, 10-20 days for 20" container |

| Payment : | (1) L/C at sight. (2) 30% T/T in advance, the balance 70% against copy of B/L(CIF) (3) 30% T/T in advance, the balance to be paid off before shipment.(FOB) |

FAQ

(1) How to prolong service life of bearings?

Accurate installation and using,alignment,timely monitor,re lubrication etc.

(2) Reason for bearings failure?

Usually is incorrect using method,pollution,improper use of lubricant,damage happened in installation and handing,also including installation error.according to the traces can know the reason why is failure.

(3) How to choose bearings?

Analyse mechanical device and use conditions.clear the requiremment of bearings.select type of bearings,select distribution way of bearings.selet dimensions of bearings,select installation method of bearings.

(4) When select bearings specifications,what you need to consider?

The precision of the bearings(rotating precision,dimensional tolerances)internal clearance and preload bearing material and heat treatment.structure of cage and material.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23