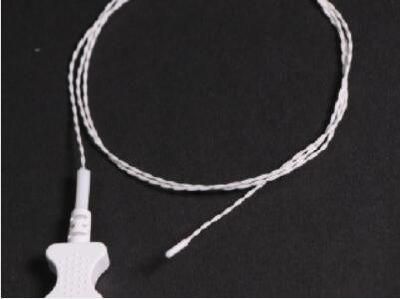

Skin Surface Temperature Probe Single Use Probe

Shantou Caiya Metal & Plastic Co., Ltd. / 2022-06-23

- Type:Surgical Supplies Materials

- Material:PVC

- Ethylene Oxide Sterilization:Ethylene Oxide Sterilization

- Quality Guarantee Period:One Year

- Group:Adult

- Logo Printing:Without Logo Printing

=== Base Info ===

- Model NO.:JP403

- Transport Package:Neutral Packing

- Specification:Ф 5.8mm

- Trademark:J. P. Sensor

- Origin:Hefei, Anhui, China

- HS Code:9025199090

- Production Capacity:50000PCS,Year

=== Description ===

- B-constant(B25/50) change should be less than ±2%.

- No visible damage

| Step | 1 | 2 | 3 | 4 |

| Temp.(deg.C) | -55+0/-3 | Room Temp. | 125+3/-0 | Room Temp. |

| Time (min.) | 15±3 | 1 | 15±3 | 1 |

- B-constant(B25/50) change should be less than ±2%.

- No visible damage.

- B-constant(B25/50) change should be less than ±2%

- No visible damage.

- B-constant (B25/50) change should be less than ±2%

- No visible damage

Adhesive foam evaluated by bio-compatibility can be fixed on measuring position, it is with no irritation to the skin and with better comfort. The foam reflector can effectively insulate ambient temperature and radiant light to ensure normal operation.

Adhesive foam evaluated by bio-compatibility can be fixed on measuring position, it is with no irritation to the skin and with better comfort. The foam reflector can effectively insulate ambient temperature and radiant light to ensure normal operation.FAQ:

Q: Can you show the match behind conversion from % tolerance to actual temperature tolerance?

A: To determine the temperature accuracy simply divide the total deviation (resistance tolerance) by the Alpha for the temperature of interest.

Q: Does the thermistor accuracy specifications include any long term resistance change over time (resistance stability)?

A: No, the accuracy is specified as the accuracy of the sensor shipped. We have no control of the application or the environmental conditions the sensor will be subjected to in the field.

Q: What does % mean when talking about temperature accuracy?

A: Sensor's accuracy can be specified as resistance tolerance or to a temperature accuracy at either a single point at ... over a span.

Q: What advice can you give for glueing a thermistor to a metallic surface have?

A: Adhesives are used in many applications to attach a thermistor for surface temperature measurement. A thermally conductive adhesive, usually epoxy, will give optimal results.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23