Custom Aluminum Alloy Gravity Die Casting Transmission Housing

Dongguan Hongye Packing Material Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery

- Function:Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase

- Layout:Cycloidal

- Hardness:Hardened Tooth Surface

- Installation:Vertical Type

- Step:Single-Step

=== Base Info ===

- Model NO.:Cusotmized

- Type:Cylindrical Gear Box

- Item Name:Alloy Gravity Die Casting Transmission Housing

- Casting Material:Aluminium Alloy Zl101, A356, ADC12, Alsi7mg

- Manufacturing Process:Die Casting, Option Gravity Casting, Low Pressure

- Casting Tolerance:CT5-7 for Aluminum Casting

- Machining Process:CNC Machining, Lathing, Milling, Turning, Boring,

- Surface Treatment:Anodize, Painting

- Rough Surface Roughness:Ra3.2-25 Fortransmission Housing

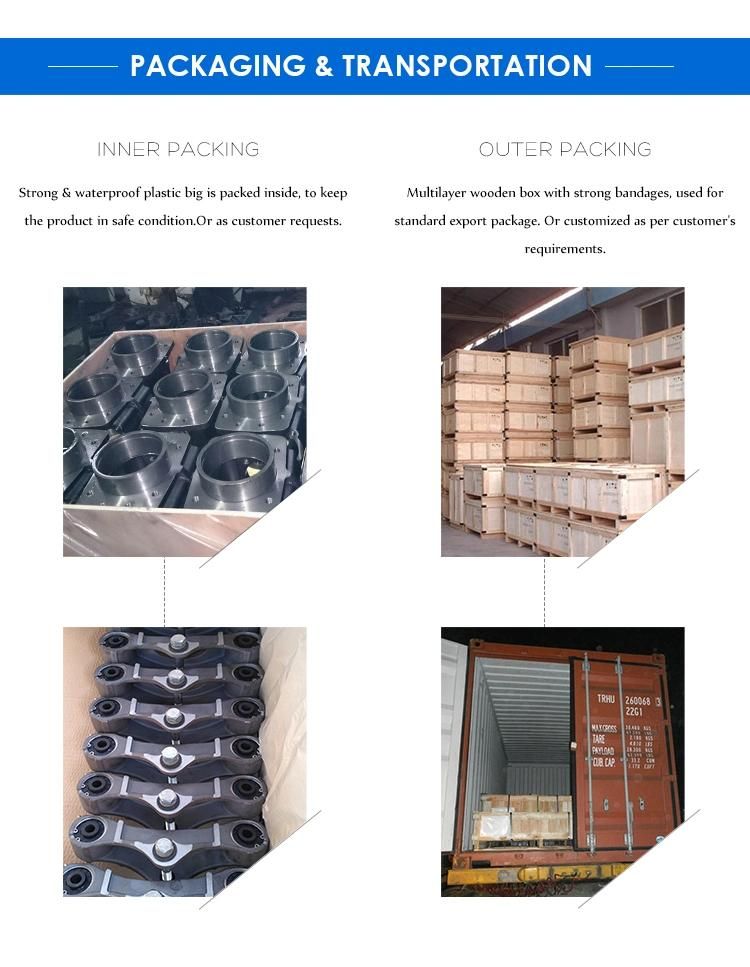

- Package:Multiplayer Wood Box,Pallet, with Big Plastic Bag

- Lead Time:45 Days for Transmission Housing

- Service:Custom Based on Drawing or Sample

- Transport Package:Multiplayer Wood Box,Pallet

- Specification:Customized Size

- Trademark:Matech Industry

- Origin:China Zhejiang

- HS Code:8701901990

- Production Capacity:150 Ton,Month

=== Description ===

Basic Info.

Model NO. Cusotmized Type Cylindrical Gear Box Item Name Alloy Gravity Die Casting Transmission Housing Casting Material Aluminium Alloy Zl101, A356, ADC12, Alsi7mg Manufacturing Process Die Casting, Option Gravity Casting, Low Pressure Casting Tolerance CT5-7 for Aluminum Casting Machining Process CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Surface Treatment Anodize, Painting Rough Surface Roughness Ra3.2-25 Fortransmission Housing Package Multiplayer Wood Box/Pallet, with Big Plastic Bag Lead Time 45 Days for Transmission Housing Service Custom Based on Drawing or Sample Transport Package Multiplayer Wood Box/Pallet Specification Customized Size Trademark Matech Industry Origin China Zhejiang HS Code 8701901990 Production Capacity 150 Ton/MonthProduct Description

PRODUCT INFORMATION

| Item Name | Custom Aluminum Alloy Gravity Die Casting Transmission Housing |

| General Products Application/Service Area | Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Agriculture machine metal Parts, etc. |

| Main blank Process for Aluminum Casting | Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting, . |

| Blanks Tolerance -Casting Tolerance | CT4-6 for Permanent Molding, Die Casting, |

| Applicable Material for casting | A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/ Or according to customer requirements |

| Casting Blank Size /Dimensions | 2 mm-1500mm / 0.08inch-60inch , or according to customer requirements |

| Casting Blank Weight | Range from 0.01kg-50kg |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment | T5~T6 |

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating, Finish Painting, Anodize (White or Black Color) |

| MOQ | For aluminum casting : 200pcs For Machining: 50pcs |

| Lead Time | 45days from the receipt date of deposit for Transmission Housing |

Product Show

Comapny Inforamtion

Production Show

Packing

Technology

Match Industry Ltd.can supply ONE-STOP service to you from die casting, machining to surface treatment. Time and cost will be saved for you.

There are 12 die casting machines and furnaces in factory. The casting machine specification is from 200 ton, 400 ton to 800 tons. The capacity is over 25 tons per month. The furnace size is 500 Kg.

There are 15 professional engineers whose experience over 8 years. We can supply feasible analysis for you. Speed and precision are our aim.

Casting pouring simulation can be supplied if it's needed. Melting filling the mold and cooling status (speed and consequence) are clearly simulated, concentration of over heat positions and potential casting shrinkage can be early identified and avoid by pre-actions.

What we supplied is high precision customized part of vehicle and machinery. It is sure that we can bring value to you.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23