9 Inch Slewing Drive Used for Wind Power Generation

Jinjiang Huawin Chemical Co., Ltd. / 2022-06-27

- Holding Torque:38.7kn.M

- Tilting Moment Torque:33.9kn.M

- Output Torque:7320n.M

- Solar Tracker:Single and Dual Axis

- Slewing Drive:Worm Gear

- 24VDC Motor:24V Sun Tracker Motor

=== Base Info ===

- Model NO.:SC9-61-RC-24H15300-RV. A

- Keyword:Slew Worm Gear Drive

- Application:Solar Power System

- Transport Package:Wooden Case

- Specification:SC9-61-RC-24H15300-RV. A

- Trademark:Coresun Drive

- Origin:Changzhou, China

- HS Code:8483409000

- Production Capacity:5000PCS,Month

=== Description ===

Model

SC9

IP

IP65

Brand

Coresun Drive

Available Load Weight

500-800kg

IP Class

IP65

Output Torque

854N.m

Tilting Moment Torque

33.9KN.m

Holding Torque

38.7KN.m

Mounting Bolts

M16

24VDC

Gear Ratio

61:1

Efficiency

40%

Coresun Drive Equipment Changzhou Co., Ltd. Slewing drives function with standard worm technology, in which the worm on the horizontal shaft acts as the driver for the gear. The rotation of the horizontal screw turns a gear about an axis perpendicular to the screw axis. This combination reduces the speed of the driven member and also multiplies its torque; increasing it proportionally as the speed decreases. The speed ratio of shafts depends upon the relation of the number of threads on the worm to the number of teeth in the worm wheel or gear.

Slew Drive is a new type of slewing product, usually called slewing ring, which is usually composed of worm, slewing ring, housing, motor and other components. Since the core components are slewing bearings, they can simultaneously withstand axial forces, radial forces, and overturning moments. Compared with traditional rotary products, the new slewing drive features easy installation, easy maintenance and a greater degree of installation space.

Slew Drive are widely used in PV,CPV,STP solar tracking systems and construction applications including truck cranes, manlifts, turntables, port machinery, modular vehicles, small wind power systems and satellite communications.

3.With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4.Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality.The company has complete testing equipment and advanced testing method.5.Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

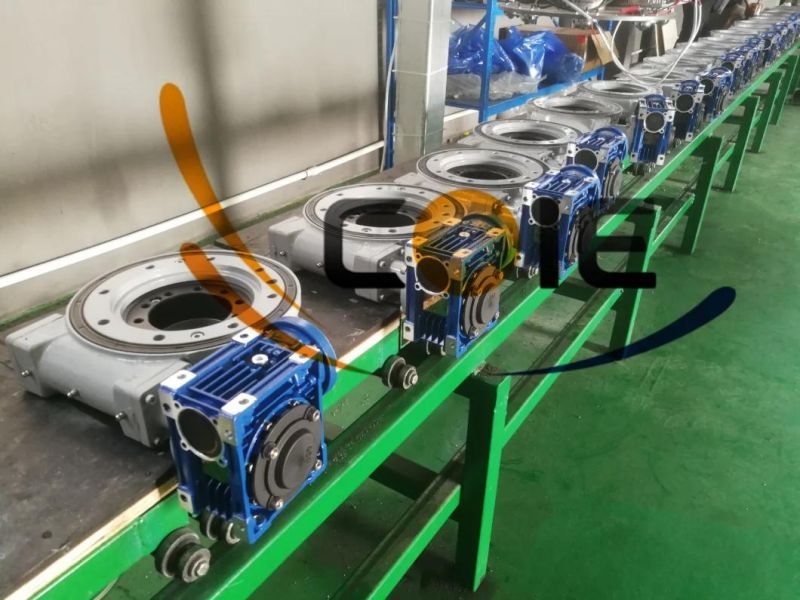

Coresun Drive Slewing Drive Motor Production Photo and Application

Coresun Drive processes the metallography detection to check the material and organization structure of worm shaft,slewing gear and casting housing.

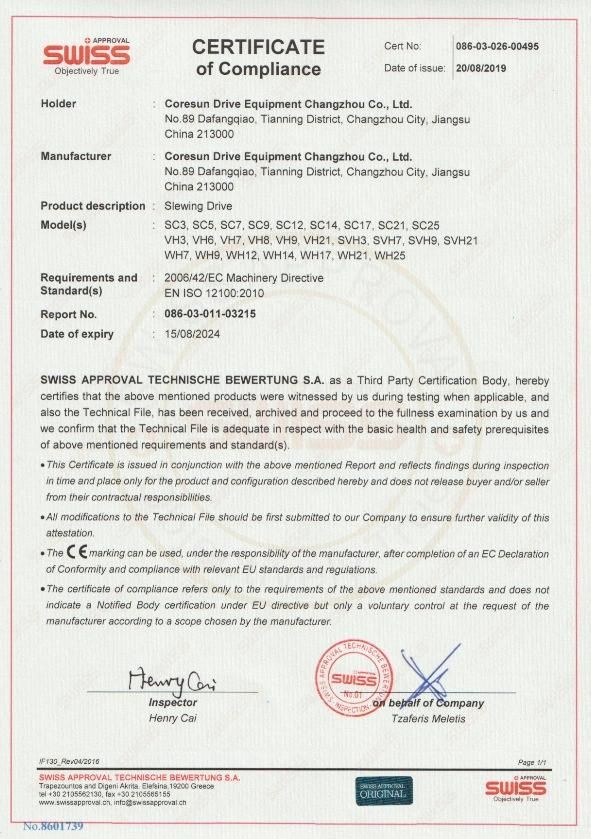

Coresun Drive slewing drive gear motor with 24VDC motor is certificated by CE

CONTACT US

It is sincerely looking forward to cooperating with you for and providing you the best quality product & service with all of our heart!

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23