130.25.560 694mm Triple Rows Rollers Slewing Bearing Without Gear

Guangzhou Jn Trading Co., Ltd. / 2022-06-08

- Standard or Nonstandard:Standard

- Feature:High Speed, Antimagnetic, Cold-Resistant, Corrosion-Resistant, Heat-Resistant

- Sealing Gland:Sealed On Both Sides

- Rolling-Element Number:Multiple-Column

- Roller Type:Deep Groove Raceway

- Material:Bearing Steel

=== Base Info ===

- Type:No Gear

- Transport Package:Cloth

- Specification:Customized

- Trademark:HBB

- Origin:Luoyang, China

- Production Capacity:30000 PCS Yearly

=== Description ===

Basic Info.

Type No Gear Transport Package Cloth Specification Customized Trademark HBB Origin Luoyang, China Production Capacity 30000 PCS YearlyProduct Description

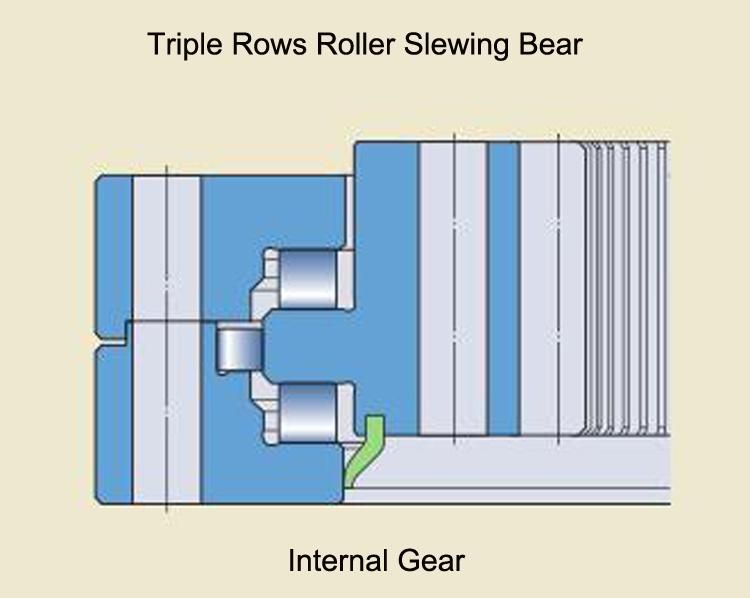

HBB High Performance Triple Rows Roller Bearings without GearNormally, Slewing Bearings are large-size rolling bearings that can accommodate axial,radial and moment loads acting either singly or in combination and in any direction. They can perform both slewing (oscillating) movements as well as rotational movements.

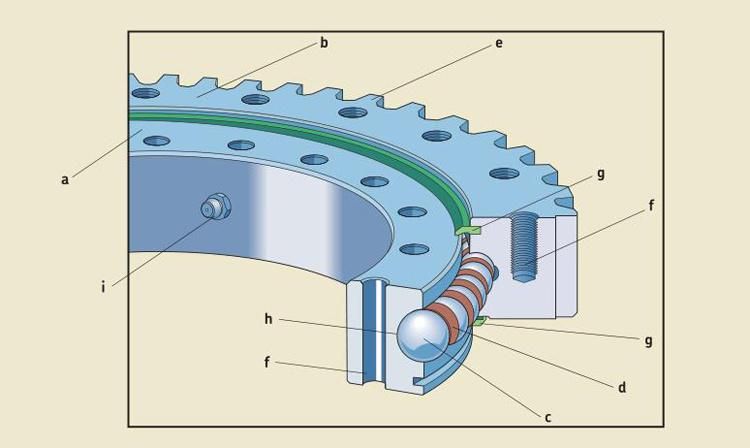

Basically, a slewing bearing consists of an inner ring (a), an outer ring (b) and rolling elements − balls (c) or cylindrical rollers − that are separated by polyamide spacers (d). The rings, one of which usually incorporates a gear (e), are provided with holes (f) to accommodate attachment bolts. The holes may be threaded. Generally, only the raceways in the rings (h) are hardened and precision-ground. Integral seals (g) made of acrylonitrile-butadiene rubber (NBR) keep the lubricant in, and contaminants out of the bearing. Slewing bearings are re-lubricated Slewing bearings through grease fittings (i) to reduce maintenance and operating costs.

Compared to traditional pivot arrangements, slewing bearing arrangements provide many design and performance advantages. The compactness and large inner diameter simplify the design of the bearing arrangement and its associated components.

The low sectional height of these bearings means that the pinion lever can be kept short. In most cases only flat surfaces on the associated components are needed.

Slewing bearings were originally designed to be mounted only on horizontal support structures, but can now be used successfully in vertical bearing arrangements. The forces and load distribution in slewing bearings, when subjected to axial, radial and moment loads.

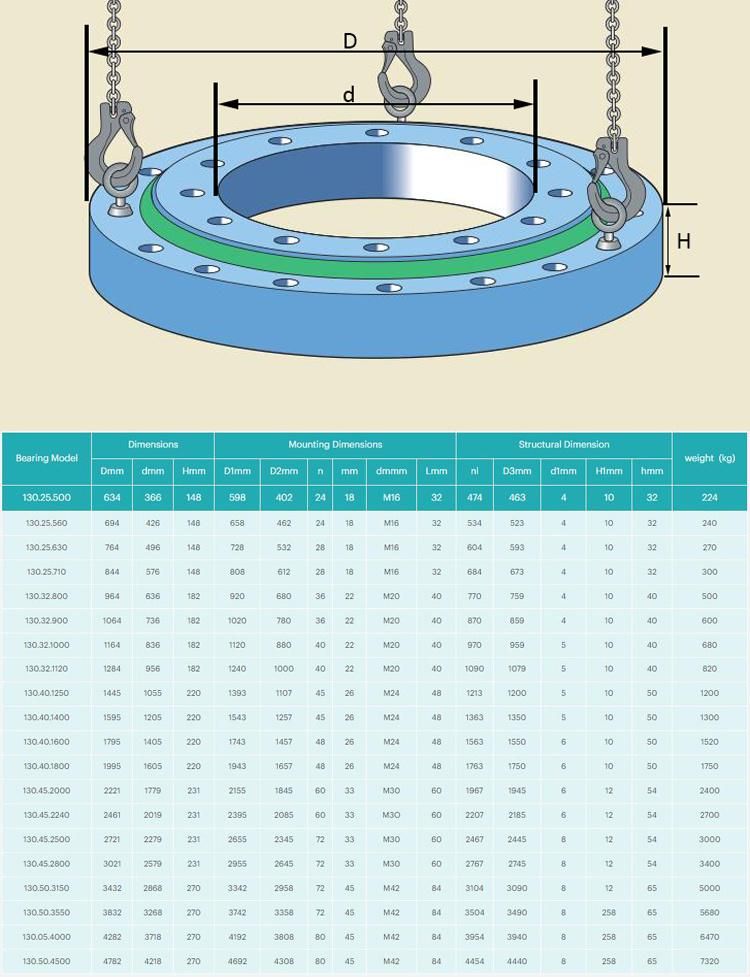

Technical Speficiations:

Slewing bearings perform extremely well in a variety of applications such as:

access platforms; bucket wheel excavators; conveyor booms; cranes of all types, small, medium and large excavators; indexing tables; ladle turrets; offshore applications; robots; railway bogies; rotary platforms; stackers; solar mirrors; tunnel boring machines; wind turbines; radar antenna

Real Products Show:

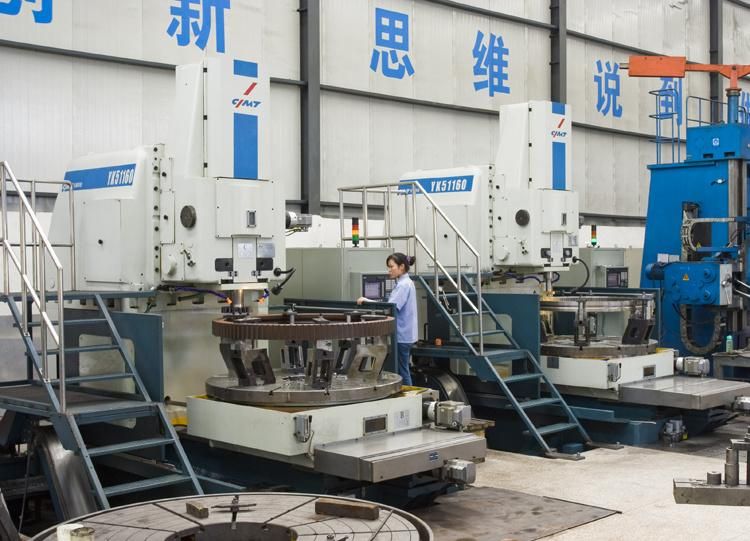

Factory Show:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23