High Quality Disposable Medical Protective Clothing

Yudong Packaging Products Co., Ltd / 2022-06-23

- Feature:Disposable

- Certification:FDA, ISO9001:2015

- Ethylene Oxide Sterilization:Ethylene Oxide Sterilization

- Application:Hospital

- Group:Medical Care Personnel

- Logo Printing:With Logo Printing

=== Base Info ===

- Model NO.:protective clothing

- Transport Package:Cartons

- Specification:HTG-160, HTG165, HTG-170, HTG-175, HTG180, HTG-185

- Origin:Shenyang

- HS Code:3926209000

=== Description ===

Basic Info.

Model NO. protective clothing Transport Package Cartons Specification HTG-160, HTG165, HTG-170, HTG-175, HTG180, HTG-185 Origin Shenyang HS Code 3926209000Product Description

Medical Disposable Protective Clothing[Product name] Medical Disposable Protective Clothing

[Specification/ model] Model: conjoined (Ethylene oxide sterilization); specifications:

HTG-160, HTG-165, HTG-170, HTC-175, HTG- 180, HTG- 185

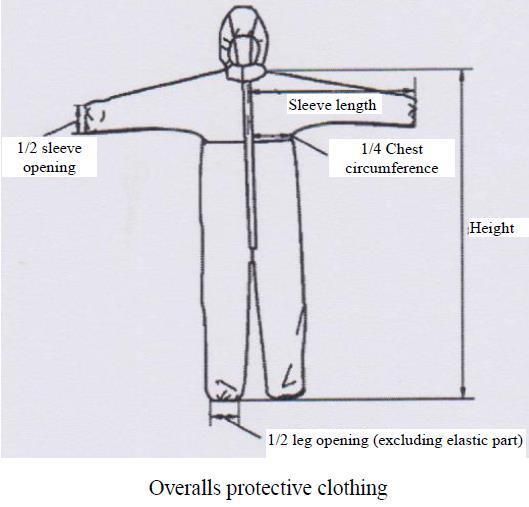

[Structure and Composition] This product is made of nonwoven fabric (non-woven fabric made of polypropylene and polyethylene) by seaming and sticking adhesive strip (main material is polyethylene). The protective clothing is a conjoined structure with hoodie and pants. The cuffs and ankle mouths are closed up with elasticity. The cap face closing and waist are closed up with elastic stay cord. This product is sterilized by ethylene oxide and provided sterile for disposable use.

[Product performance] The hydrostatic pressure at the critical part of the protective clothing should not be lower than 1.67 kPa (17cm H2O); The moisture permeability of protective clothing materials should not be lower than 2,500g/(m2•d); Protective clothing against synthetic blood penetration should not be lower than Level 2 (1.75kPa); The spray rating on the outer side of the protective clothing should not be lower than Level 3; The breaking strength of the key parts of protective clothing should not be lower than 45N; The breaking elongation of the key parts of protective clothing should not be lower than 15%; The filtration efficiency of non-oily particles at the key parts and seaming of the protective clothing should not be lower than 70%; Flame retardant performance: damage length not greater than 200 mm; Continue burning time not more than 15s; Fire resistance time not more than 10s; The electric charge of protective clothing should not be larger than 0. 6μC/pcs; The electrostatic attenuation of the protective clothing materials should not be longer than 0.5s; The product should be sterile, and ethylene oxide residue should not exceed 10μg/g.

[Application scope] It is suitable for medical personnel to be isolated and protected from contact with blood, body fluids and secretions of potential infectious patients.

[Instructions]

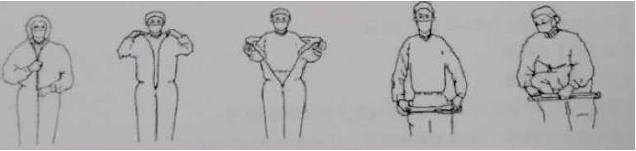

1. Methods to take on protective clothing:

Protective clothing should be taken on following the order of pants, coat, hat, and zipping up.

2. Methods to take off protective clothing:

Pull the zipper to the end. Lift the hat up so that it is off the head and off the sleeve; Take off up and down with the contaminated surface inside and place in the bag of medical waste.

[Precautions, warning and indicative explanation]

- Check whether the package is in good condition before use, and confirm the outer packing mark, production date, validity period and use it during the sterilization validity period.

- If the package is damaged before use, it is forbidden to use it.

- This product is disposable and should not be repeated in use.

- Please stop using immediately if allergic.

- Protective clothing should be taken on/off in a specified area.

7. When the protective clothing is contaminated by the patient's blood, body fluid and dirt, it should be replaced in time.

8. Protective clothing can be used continuously when medical personnel are exposed to multiple patients with similar infectious diseases.

9. The product should not be discarded at will according to the treatment requirements in Medical Waste Management Regulations.

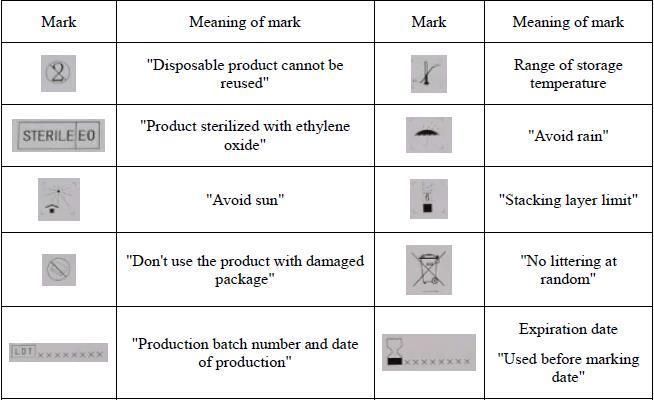

[Explanation of Symbols]

[Transportation and storage environment] The product should be stored in a ventilated and dry environment without harmful gas and keep away from the fire source and pollution. The product should avoid sunlight and rain during the transportation process.

[Contraindications] NA

[Preparation date of the instructions] February 25, 2020

[Expiration date] See the label

[Production date] See the label

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23