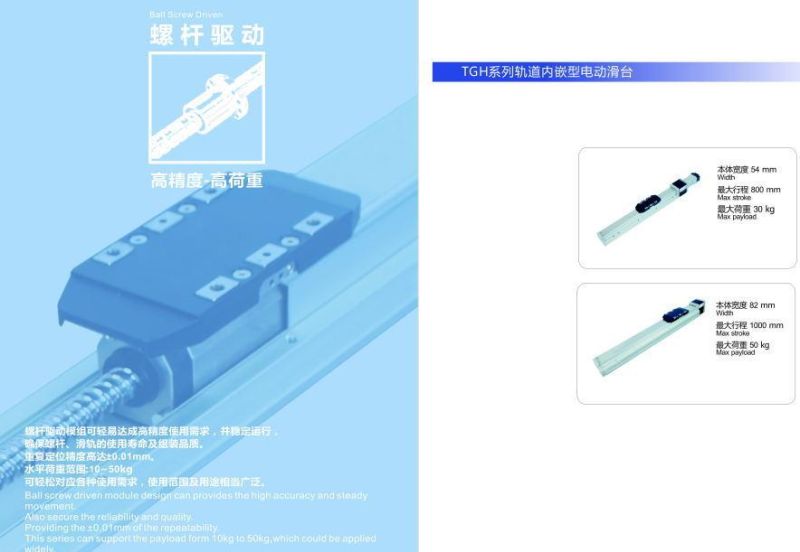

Precise Built-in Linear Actuator for 3D Printer

Xiamen Bestlink Factory Co., Ltd. / 2022-06-27

- Standard or Nonstandard:Standard

- Surface Treatment:Oxygenation

- Material:Aluminum

- Body Width:54mm to 82mm

- Max Stroke:800mm to 1000mm

- Max Playload:30kg to 50kg

=== Base Info ===

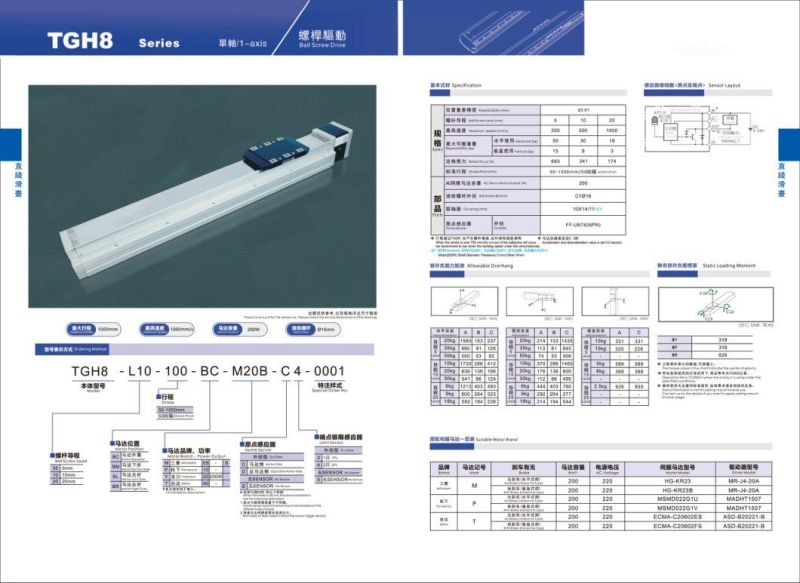

- Model NO.:TGH5, TGH8, TGH12

- OEM:Yes

- Driven:Ball Screw

- Sealed Structure:Yes

- Transport Package:Carton Box or Wooden Case

- Specification:TGH5, TGH8, TGH12

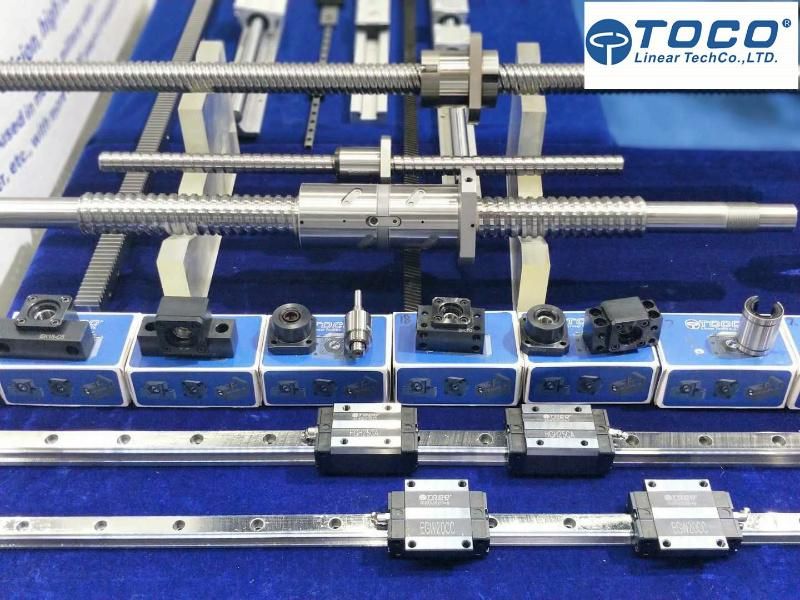

- Trademark:TOCO

- Origin:China

- HS Code:8487900000

- Production Capacity:5000 Sets,Month

=== Description ===

Basic Info.

Model NO. TGH5, TGH8, TGH12 OEM Yes Driven Ball Screw Sealed Structure Yes Transport Package Carton Box or Wooden Case Specification TGH5, TGH8, TGH12 Trademark TOCO Origin China HS Code 8487900000 Production Capacity 5000 Sets/MonthProduct Description

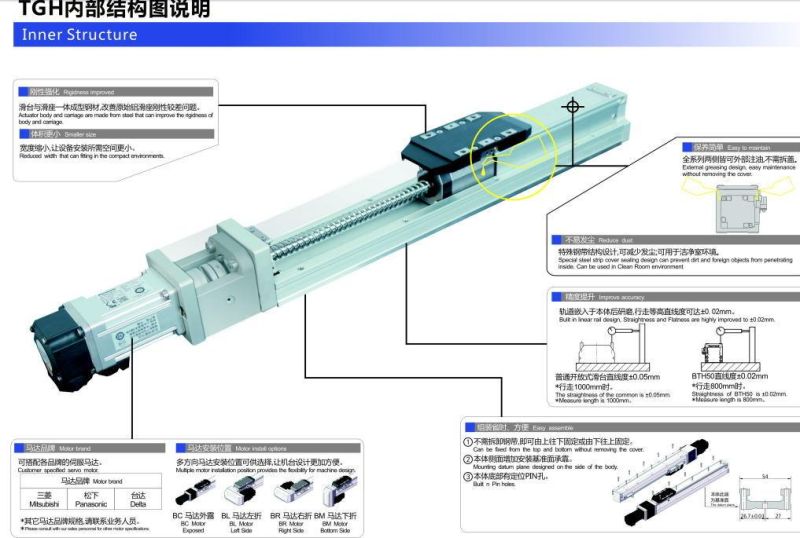

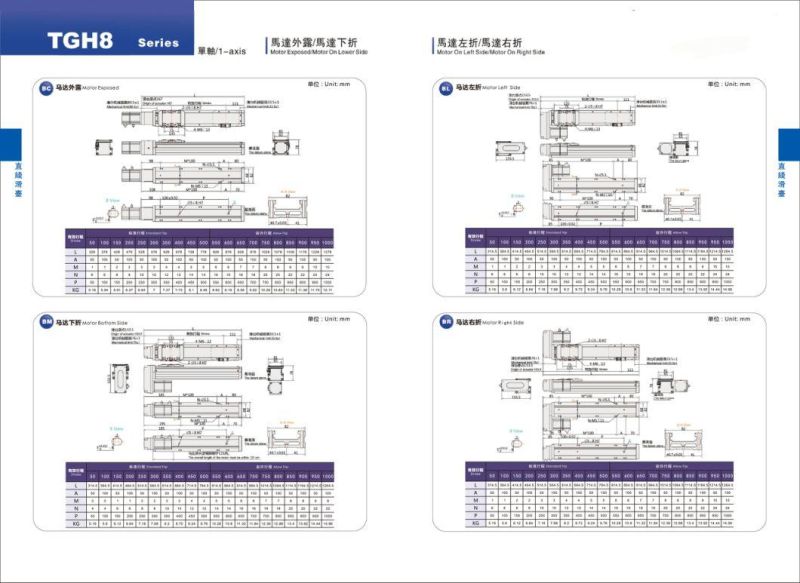

Features1. Available in three sizes in TGH5, TGH8, TGH12.

2. Repeatability of up to ± 0.01mm

3. Powerful ball screw drives for reliable movements.

4. Extremely compact aluminum frame with high inherent stiffness

5. Max Stroke of 800mm to 1000mm. Fully sealed structure, body width 54mm to 82mm, it is designed for dustproof usage in a hard environment, avoid dust or miscellaneous debris fall into body structure to affect working, high-temperature resistance, long service life.

6. Rigidness improved, Smaller size, Easy to maintain, Reduce dust, Improve accuracy, Easy assemble, etc.

Operation

1. The operation conditions need to be within the rated values as shown in the technical information.

2. Avoid dust, debris, and any foreign objects from entering the ball return system.

3. The operational temperature should be under 80 ºC. In high-temperature environments above 80ºC.

4. If the product can be used in a special environment, such as vacuum, vibration,

clean room, corrosive chemicals, organic solvents, extremely high or low temperatures, humidity, liquid splashes,

oil drops or mist, high salt, heavy load, vertical or cantilever installations. Please Confirm first with TOCO.

5. For vertical installations, when loaded, there is a possibility that the slider may fall. We recommend adding

proper braking and ensure functionality before the operation.

Maintenance

1. Lubricate the product before the initial use. Note the type of grease used and avoid mixing different types together.

2. For normal operating conditions, it is recommended to check the operation every 100km, clean and supply grease onto the rail and shaft.

Catalogs

Package & Shipping

1.Package: Carton or wooden case.

2.Delivery time: 15 days after receiving payment.

3.Shipping: by express (DHL, TNT, FedEx, etc.) or by sea.

TOCO Exhibition

Company

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23