Helical Pinion Shaft Gear with Good Quality

XIAMEN HONGJU UNITED TECHNOLOGY CO., LTD. / 2022-06-27

- Application:Agricultural, Motor...

- Hardness:Hardened

- Manufacturing Method:Cast, Rolling,Cut,Sintered Gear

- Toothed Portion Shape:Bevel Wheel

- Material:Stainless Steel, Iron, Aluminium, Copper etc

- Type:Bevel Gear

=== Base Info ===

- Model NO.:Customized

- Manipulate Way:Forced Manipulation

- Changes Way:Stepped

- Transport Package:Wooden,

- Specification:customized

- Trademark:OEM,ODM

- Origin:Laixi Qingdao City N

- Production Capacity:50000,Month

=== Description ===

Basic Info.

Model NO. Customized Manipulate Way Forced Manipulation Changes Way Stepped Transport Package Wooden/ Specification customized Trademark OEM/ODM Origin Laixi Qingdao City N Production Capacity 50000/MonthProduct Description

| casting technology | investment casting/silic sol investment casting/lost wax casting |

| casting material | carbon steel, stainless steel, alloy steel and etc |

| material standard | AISI JIS GB DIN EN ASME |

| casting parts range | automobile parts, machinery parts, marine hardware parts, door lock parts, pump valve and pipe fittings parts, bathroom hardware, kitchen hardware and so on |

| casting weight | 2g-70kg |

| surface finishing | sand blasting, stain polishing, mirror polishing, chrome plated, painted or as customer's request |

| machining | milling, drilling, grinding, CNC machining |

| delivery time | 15days for making molds and samples confirming, then 25-30days for trial order |

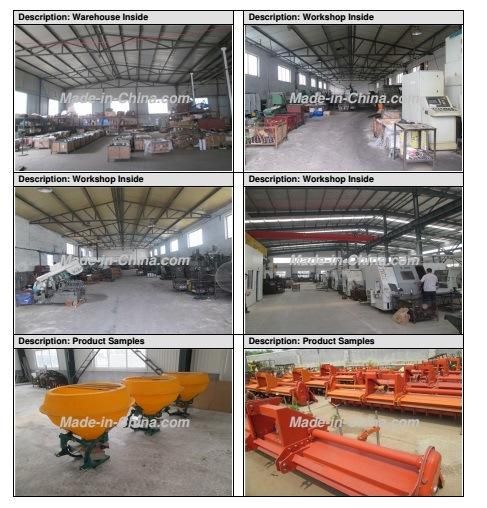

Our Company can offer you :

Steel Gear Wheel/Gear Wheel/Forged Gear Wheel/Forged Steel Gear /Wheel Shaft Spiral Bevel Gear

Customized gear

ISO9001, 2008;SGS Certificate

OEM is acceptable.

Good quality and low price

Contace us without hesitation

1 Material: Stainless Steel brass iron aluminum

2Sand and investment casting(precision casting)are all avalable

3 Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF and Solidwork 2008 flow analysis

4Further machining work: Turning and cutting, milling, grinding, drilling, reaming and threading

5Surface finish process: Shot blast, chromate plating, power coated and anodizing

6OEM/ODM parts range: Auto parts, electronic parts, furniture parts, home appliance and other industrial uses

7Process: CAD surface, matel processing, surface plating, QC testing and packaging

8Made according to customers' drawing, sepecification or/ and samples

Please do not hesitate to contract with us, our working and products is your best chioce.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23