Best Quality Carbide Cermet Diamond Tipped TCT PCD HSS Circular Cold Saw Blade For Wood & Aluminium Cutting.

Zhejiang Alwsci Technologies Co., Ltd. / 2022-06-09

- Certification:ISO9001:2008, ISO9001:2000, RoHS, CE, BV

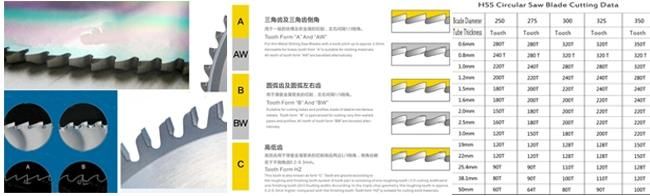

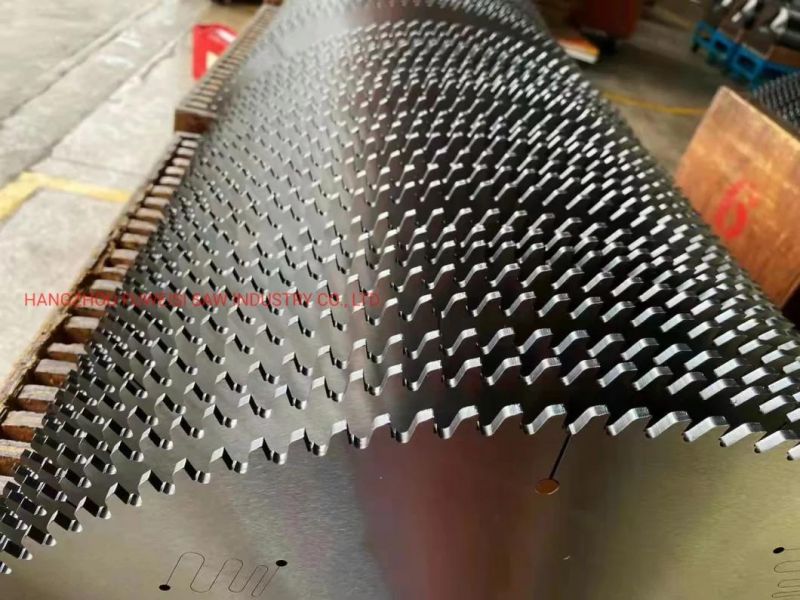

- Tooth Form:Bw,Hz,a,Aw

- Diameter:550mm

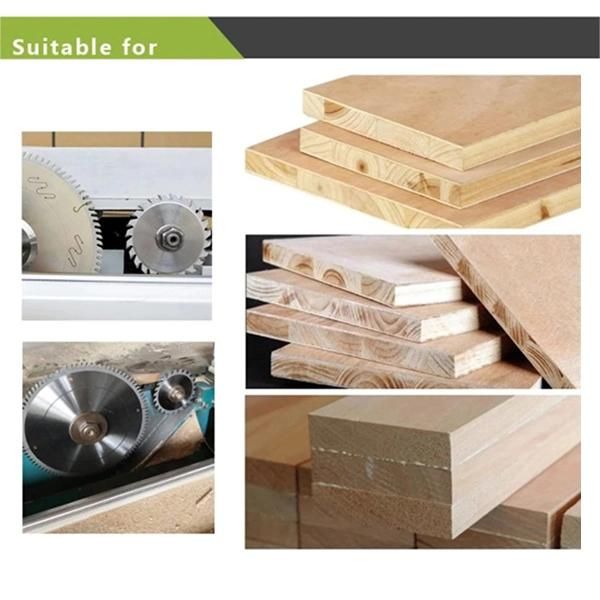

- Function:Cutting

- Coating:PVD

- Type:HSS Saw Blade

=== Base Info ===

- Hardness:HRC62-65

- Tooth Grinding:CNC Tooth Grinding Machine

- Heatment Treatment:Salt Bath

- Tooth Number:Z=220

- Material:High-Speed Steel

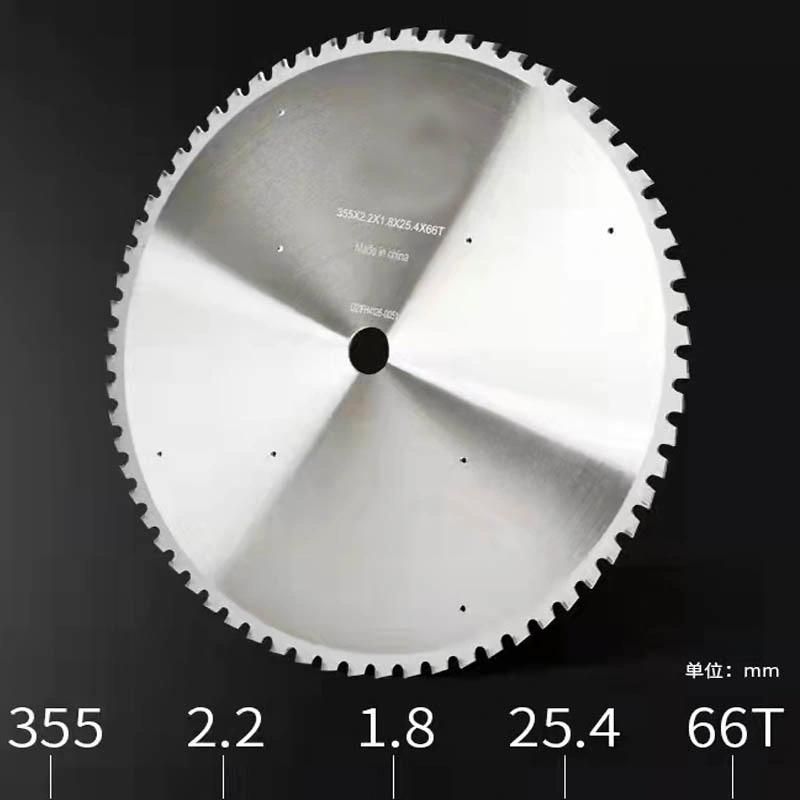

- Thickness:1.2mm,1.6mm,2.0mm,2.5mm

- Bore:32mm,40mm

- Delivery Time:4-6 Weeks After Order

- Transport Package:5PCS Per Case

- Specification:550x3.5x90mm

- Trademark:FUWEISI, BOSS CUT

- Origin:Germany, Japan and USA Material.

- HS Code:8202399000

- Production Capacity:30000PCS Per Month

=== Description ===

Basic Info.

Hardness HRC62-65 Tooth Grinding CNC Tooth Grinding Machine Heatment Treatment Salt Bath Tooth Number Z=220 Material High-Speed Steel Thickness 1.2mm,1.6mm,2.0mm,2.5mm Bore 32mm,40mm Delivery Time 4-6 Weeks After Order Transport Package 5PCS Per Case Specification 550x3.5x90mm Trademark FUWEISI, BOSS CUT Origin Germany, Japan and USA Material. HS Code 8202399000 Production Capacity 30000PCS Per MonthProduct Description

Hangzhou FUWEISI Saw Industry Co.,ltd. was established in Lishui city, zhejiang province of China in 2000, with factory for more than 50000 square meters and 660 staff. Company got "Direct-Export license" in 2005, and now is a SGS certified supplier.

For HSS saw blades, what we do is from 32mm to 600mm for diameter and in all thickness and bore sizes, We only use certified HSS M2 and M35 material, and manufactured by most moden CNC machinery, together with Swedeen PVD coating process. And tooth grinding done by CNC grinding machine in order to gurantee tooth sharp and durable in all tooth number & forms.

Thanks for the hard working of our staff and kind support of customers, company have benn enjoying a good reputation home and abroad. In overseas, customers are in more than 20 countries and regions, such as Korea, India, USA. Brazil. Russia, etc.

Looking at future, customers from home and abroad are welcomed to establish a mutual beneficial long term co-operation.

Hiqh quality HSS TIN saw blade

Type:

Tin-coated(Titan-Nitrid)

Tooth form:

A/AW/B/BW/Hz

Diameter:

200mm; 225mm, 275mm, 300mm,

315mm, 350mm, 370mm, 400mm, 425mm, 450mm,500mm,550mm,600mm.

Thickness:

1.2mm; 1.6mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm. 4.0mm.

Bore diameter:

32mm, 38mm, 40mm, 50mm or customer bore size.

Technical data ot Tin coating:

Colour: Gold

Process: PVD

Hardness: 2500HV

Friction: 0.4

Thickness: 1-4mm.

Max cutting temperature: 600 degree.

Operation:

Structural steel

Alloyed steels

Steel pipes and profiles

Pipes and profiles out non ferrous metals

Technical recommendation:

Raising of the coating hardness by reducing the friction

Universal coating for better sawblade life

50-100%higher speed and feed rates

Prevention of side pick-UPS

Production is based on DIN standards 1836, 1837, 1838 and 1840, extended by the refined "FUWEISI" manufacturing standards. The delivery program consists of a range of standard sawblades which can be delivered from stock and a range of special sawblades to be produced to customer specifications.

The HSS TIN sawblades are supplied as standard in high speed steel grade M2 = DIN 1.3343. It suits for the cutting of the materilas like stainless steel, iron pipe, steel pipe, etc.

All the products haven been enjoying an excellent reputation in the world market for it's competitive price and excellent quality.

Why choose FUWEISI Saw Industry?

- 20 Years experience in saw blade manufacturing.

- Professional sales & technical team at your service.

- FUWEISI Saw Industry is specialized in providing whole metal/wood cutting blades and solutions for customers.

- Factory with the best competitive price and quality .

- Directly after-sales service from Factroy

- Owned different certificates such as CE, TUV,SGS, ISO9001, etc.

- Yes, we can make OEM for saw blades according to your requests,but we have minimum order qty to start.

- Quality: 100% assured by strict QC system,and manufactured according to export standard.

- Normally we will accept T/T or L/C. More details can be discussed case by case.

- 15 to 60 days after received deposit. Special situation can be discussed case by case.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23