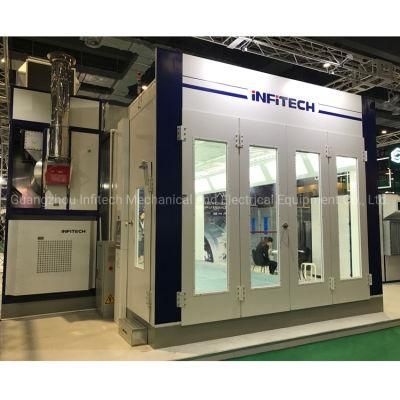

Full Downdraft Spraying Painting Booth for Auto Refinishing

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Fully Undershot-type

- Heating Mode:Diesel

=== Base Info ===

- Paint Mist Treatment:Dry-type

- Condition:New

- Basement:350mm(H)

- Carrying Capacity:900kg,Wheel

- Product Entry Door:3400mm Wide, 2700mm High

- Lights:LED Lamp

- Brightness:Over 1,500lux

- Air Make-up Units:2*15HP, 35,000m3,H

- Heats:Riello Diesel Burner Rg5d

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:7000 X 4000 X 2800mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Paint Mist Treatment Dry-type Condition New Basement 350mm(H) Carrying Capacity 900kg/Wheel Product Entry Door 3400mm Wide, 2700mm High Lights LED Lamp Brightness Over 1,500lux Air Make-up Units 2*15HP, 35,000m3/H Heats Riello Diesel Burner Rg5d Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 7000 X 4000 X 2800mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

Full Downdraft Spraying Painting Booth for Auto Refinishing1.FEATURESThe spraying and drying cabin IT-1101 offers downdraught airflow for painting and baking operations. The high performance model features robust cabin structure, big air volume, over 93% heat exchanger efficiency, no shadow workspace and innovative control system.

2.DETAILS

- Workspace dimensions: 7000x4000x2800mm

- Airflow: Full downdraft

- Basement: made of galvanized steel, 350mm(H), full gratings with carrying capacity of 900kg/wheel

- Product entry door: manual, with opening of 3400mm wide, 2700mm high

- Lights: LED lamp, water-proof and dust-free lighting fixtures, brightness is over 1,500lux

- Rock wool walls: solid, can resist high temperature

- Plenum: 2 feet high, the large space in the plenum allows even air distribution

- Air make-up units: 2*15HP, 35,000m3/h, no load speed is 0.35m/s, suit the application of waterborne paints

- Heats: RIELLO diesel burner RG5D, 315KW stainless steel heat exchanger

- Inverter control: regulate the working frequency of intake fan and exhaust fan, offer big savings in energy consumption in the long run

- Touch screen control system

3.FAQ

Q: Please advise the information of the filtration system.

A: The automotive spraying and drying cabin comes with pre-filtration, ceiling filtration and exhaust filtration.

- Pre-filtration: bag filter before the intake fan unit, G4 grade

- Ceiling filtration: F5 grade filters

- Exhaust filtration 01: floor filters, fiberglass filters

- Exhaust filtration 02: post filtration before exhaust fan, M-shape, activated carbon filters, G2 grade

Q: Can you offer hanging brackets inside the spraying and drying cabin for suspending auto body parts?

A: Yes. It is okay.

Q: I will need the spraying and drying cabin that comes with control of manual buttons.

A: Okay.

Q: In the bake phase, the air is circulated? What is the percentage of circulated air?

A: Yes. Approx. 90% air participates in internal circulation.

Q: Do you supply electric cables?

A: The electric cables that we supply are from the electrical appliances (lights, motor, sensors etc.) to our control box. For the electric cables from the control box to the power distribution room, they are not included in the supply scope.

Q: Is there cooling phase for the spraying and drying cabin?

A: Yes. There is temperature limiter to detect if the temperature is below the pre-set safety temperature. If the temperature detected is above the safety temperature, the motors keep working to discharge the excessive heat and cool down the cabin. Only when the booth is cooled down below the safety temperature, does the system stop.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23