Saw Blade for Steel Cutting Stainless Steel Cutting Saw Blade

Fuzhou Haomin Imp. & Exp. Co., Ltd. / 2022-06-09

- Certification:ISO9001:2008, ISO9001:2000

- Tooth Form:Tpp

- Diameter:240-750mm

- Function:Cutting

- Shape:Circular Saw Blade

- Coating:as Shown or Customized

=== Base Info ===

- Type:Carbide Saw Blade

- Model No:240-750mm

- Thickness:1.5-2.7mm

- Quality Grade:Professional Grade

- Application:Cutting Wood

- Customized Support:OEM, ODM, Obm

- Transport Package:Carton or Blister Packing

- Specification:customization

- Trademark:as show or customization

- Origin:China (Mainland)

- Production Capacity:5000000,Year

=== Description ===

Basic Info.

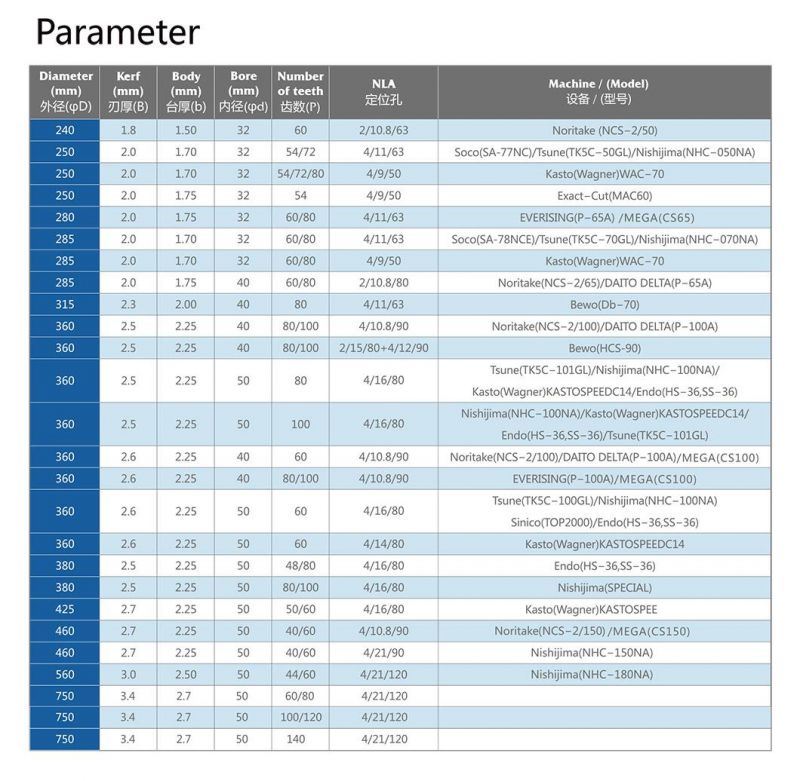

Type Carbide Saw Blade Model No 240-750mm Thickness 1.5-2.7mm Quality Grade Professional Grade Application Cutting Wood Customized Support OEM, ODM, Obm Transport Package Carton or Blister Packing Specification customization Trademark as show or customization Origin China (Mainland) Production Capacity 5000000/YearProduct Description

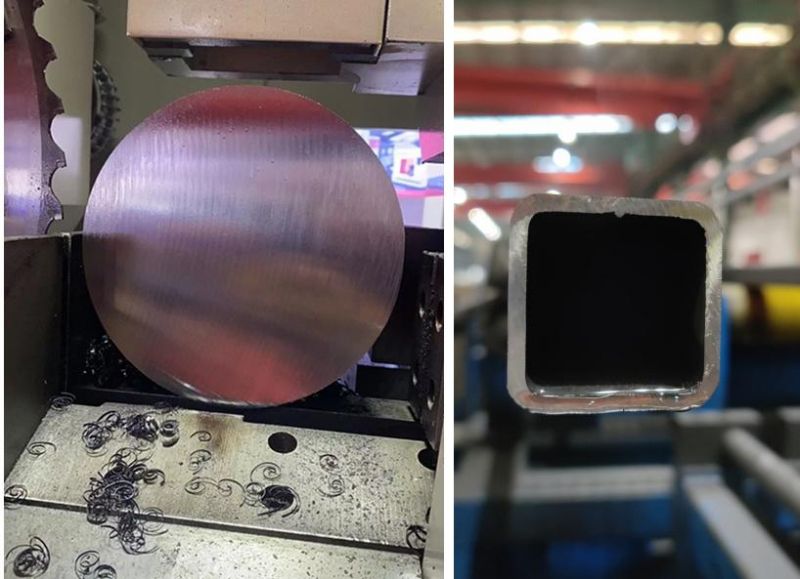

What is a cold saw blade and what are its characteristics?In the process of cutting with a circular saw, the heat generated when the saw blade saw the workpiece is transferred to the sawdust through the saw blade, and the workpiece and the saw blade remain cool, hence the name cold saw, which is what we call cold saw blade.

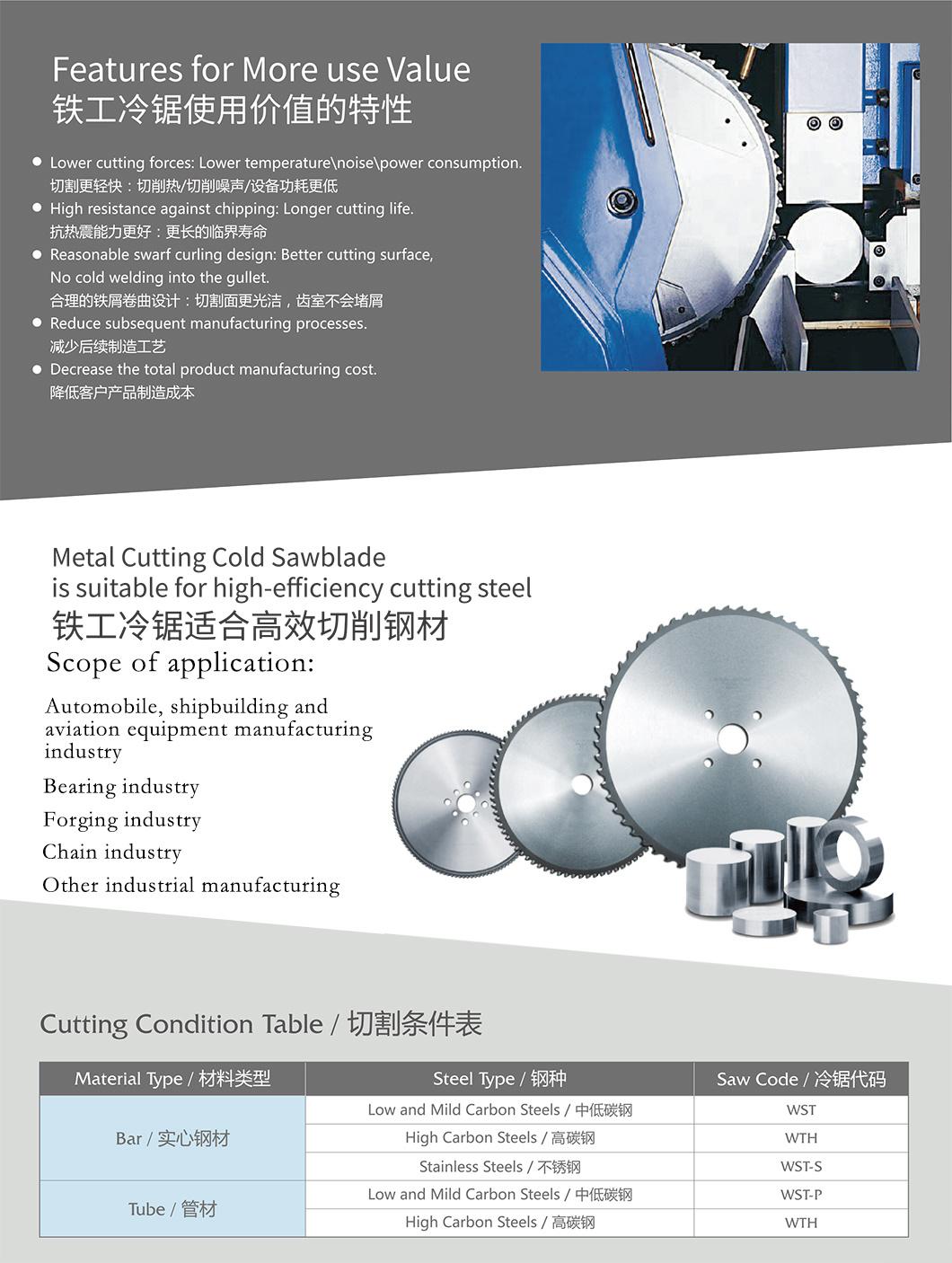

Features of cold saw blades

A. Improve the stability of the precision of the circular saw cold blade when cutting the workpiece

From the market research, according to the actual situation of use, spend a lot of manpower and material resources, developed a special technology to optimize the matrix of the saw blade, constantly improve the stability of the precision of the cold saw blade in cutting processing, in the process of cutting friction heat caused by the decrease of the matrix rigidity, has a special pit.

B. Serrated vibration can be effectively alleviated to avoid miter cutting of saw blade

Through the technical cooperation and research and development of many countries advanced saw blade manufacturers, we design the side shape of the ultra-cold saw blade, effectively reduce the vibration caused by the saw blade when cutting, control the source of the cold saw blade diagonal cutting, and reduce the adverse factors to the saw blade.

C. Increase the duration of sawing

According to different materials, different circular saw equipment classification, to achieve cold saw cutting scheme (iron cold saw blade selection diversification), to ensure the service life of sawing at the same time, more improve the quality of cutting processing workpiece.

D. Break through the speed limit, can achieve higher speed sawing operation

The use of specially treated sawtooth (commonly known as "cutter head"), flexible cutting per tooth (increase), than the market commonly used HSS saw blade will be able to operate at a higher speed; Improve the efficiency of sawing.

FAQ:1. What terms of payment are acceptable?

A: Normally we accept L/C, T/T and Western Union.

2. How can we be your agent in our country?

A: Please inform us your detailed company, we will discuss and propose helpful suggestion for you, and to find the best solution for you.

3. Do you offer free samples?

A: Normally we do not offer free samples, but we could properly adjust according to detailed requirement.

4. How is your quality?

A: We have a very seriously control system. We guarantee the high performance of our products.

5. When you can reply to me when I send you an Inquiry?

A: We promise to reply within 24 hours( including holidays) on receipt of your inquiry.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23