Professional Aluminum Profiles Cutting Tungsten Carbide Tipped Saw Blade

Fuzhou Haomin Imp. & Exp. Co., Ltd. / 2022-06-09

- Certification:ISO9001:2008, ISO9001:2000

- Tooth Form:Zy Tp

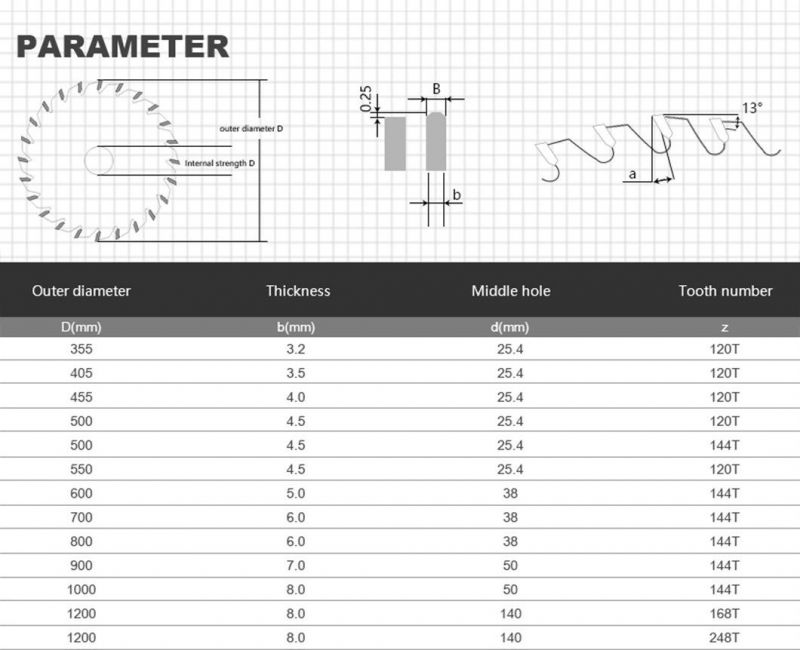

- Diameter:355-1200mm

- Function:Cutting

- Shape:Circular Saw Blade

- Coating:as Shown or Customized

=== Base Info ===

- Type:HSS Saw Blade

- Model No:250-500mm

- Thickness:3.2-8mm

- Quality Grade:Professional Grade

- Application:Cutting Wood

- Customized Support:OEM, ODM, Obm

- Transport Package:Carton or Blister Packing

- Specification:customization

- Trademark:as show or customization

- Origin:China (Mainland)

- Production Capacity:5000000,Year

=== Description ===

Basic Info.

Type HSS Saw Blade Model No 250-500mm Thickness 3.2-8mm Quality Grade Professional Grade Application Cutting Wood Customized Support OEM, ODM, Obm Transport Package Carton or Blister Packing Specification customization Trademark as show or customization Origin China (Mainland) Production Capacity 5000000/YearProduct Description

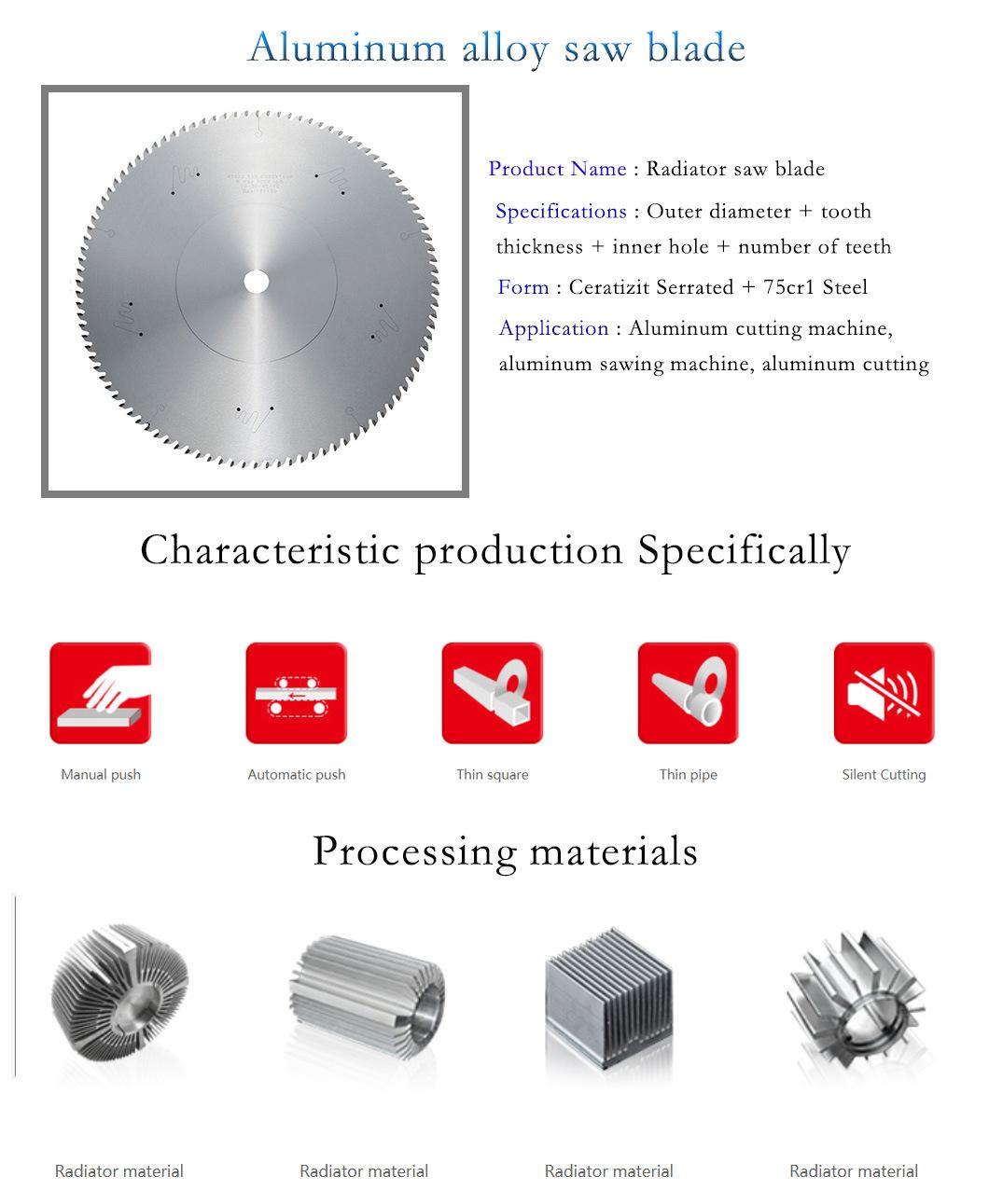

Features: Luxembourg alloy +, Germany 75Cr1 steel plate, ultra long life, ultra low noise.

Features: Luxembourg alloy +, Germany 75Cr1 steel plate, ultra long life, ultra low noise.Suitable for machinery: hand saw, cutting saw

Cutting material: aluminum tube, profile aluminum

Aluminum saw blade is the most commonly used cutting tool in aluminum processing. The quality of cemented carbide saw blade is closely related to the quality of processed products. Proper and reasonable selection of cemented carbide saw blade is of great significance to improve product quality, shorten processing cycle and reduce processing cost. The carbide saw blade contains many parameters, such as the type of alloy cutter head, material of matrix, diameter, number of teeth, thickness, tooth shape, Angle and aperture, which determine the machining capacity and cutting performance of the saw blade. The saw blade should be selected according to the type and thickness of the material, the speed of the saw, the direction of the saw, the feeding speed and the width of the saw road

Aluminum alloy saw blade tooth shape is step flat tooth, saw blade matrix, alloy cutter head and sawtooth Angle for aluminum cutting design, with cooling process, the cutting surface is smooth without burr, machining needs to be fixed by machinery, avoid shaking.

Aluminum saw blade requirements

(I) Basic Requirements:

1. Select an appropriate saw blade according to the design requirements of the equipment. 2. The equipment should be equipped with safety protection device, such as: protective cover, power off brake, overload protection, etc. 3. Professional operators should be installed and used, and wear labor clothing, protective goggles, ear muffs, etc. 4. Operators should not wear gloves, long hair should be placed in the working cap, and pay attention to ties and cuffs to prevent danger. 5. Keep away from fire and damp environment.

(ii) Installation requirements:

1, the equipment is in good condition, the spindle has no deformation, no diameter jump, solid installation and fixation, no vibration and so on. 2. Check whether the saw blade is da

Why does cutting aluminum saw blade produce burr?

When cutting aluminum saw blade saw burr, there are three main reasons, first of all, to confirm whether the saw blade itself has quality problems. The second is that the saw blade has been used for a long time, with blunt, the blade is not fast, this time it needs to be polished.

Reasons for burr during sawing:

First, the reasons for the saw blade:

1. The number of teeth of saw blade is too small.

2, saw blade quality problems. The quality problem of the saw blade, often need to take the saw blade back to the factory for maintenance, to get the quality parameters of the saw blade, such as: The wrong tooth shape, waist strength is not up to standard, the height of the sawtooth is not right, the concentricity is not good, and so on. This is also related to the customer when purchasing the saw blade, looking for what kind of saw blade supplier, finding a dedicated saw blade manufacturer. These problems will be mostly avoided when selecting the saw blade.

Two, equipment reasons:

1, spindle accuracy is not up to standard.

2, the flatness of the flange is not good or there is a foreign body, which is also a lot of enterprises will happen, we must pay attention to.

3. The straightness of saw blade walking is not good, which also requires equipment suppliers to maintain equipment frequently to prevent such problems.

4, saw blade installed backwards, although this problem is less, but there are still cases.

5. The material is not pressed, which often happens when the shape of the material is not very regular.

6, belt slip caused the saw blade speed is too low.

7. In this case, it is best to find a reliable equipment manufacturer. These problems will be explained and prevented in advance when the equipment is delivered.

Three, material reasons:

1. The material is too soft, the surface is oxidized, the material is too thin, and the deformation of the material leads to the sweeping knife after sawing, and the material brand (high silicon aluminum).

FAQ:1. What terms of payment are acceptable?

A: Normally we accept L/C, T/T and Western Union.

2. How can we be your agent in our country?

A: Please inform us your detailed company, we will discuss and propose helpful suggestion for you, and to find the best solution for you.

3. Do you offer free samples?

A: Normally we do not offer free samples, but we could properly adjust according to detailed requirement.

4. How is your quality?

A: We have a very seriously control system. We guarantee the high performance of our products.

5. When you can reply to me when I send you an Inquiry?

A: We promise to reply within 24 hours( including holidays) on receipt of your inquiry.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23