High Efficiency Full Downdraft Spray Paint Room for Auto Refinishing

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Fully Undershot-type

- Heating Mode:Diesel

=== Base Info ===

- Model NO.:IT-1101

- Paint Mist Treatment:Dry-type

- Condition:New

- Plenum (Height):600mm

- Extraction:350mm

- Extraction Area:28m2

- Walls:50mm Rock Wool Walls

- Brightness:>1,500lux

- Empty Loaded Air Speed:0.35m,S

- Noise:<78 dB

- Warranty:2 Years

- Air Volume:35,000m3,H

- Grids Carrying Capacity:900kg,Wheel

- Maximum Working Temperature:80 Celsius

- Inverter:Schneider

- Rated Power:28kw

- Heats:315kw Heat Exchanger

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:7000 X 4000 X 2800mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Model NO. IT-1101 Paint Mist Treatment Dry-type Condition New Plenum (Height) 600mm Extraction 350mm Extraction Area 28m2 Walls 50mm Rock Wool Walls Brightness >1,500lux Empty Loaded Air Speed 0.35m/S Noise <78 dB Warranty 2 Years Air Volume 35,000m3/H Grids Carrying Capacity 900kg/Wheel Maximum Working Temperature 80 Celsius Inverter Schneider Rated Power 28kw Heats 315kw Heat Exchanger Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 7000 X 4000 X 2800mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

High Quality Full Downdraft Industrial Spraying Booth for Auto Body Shops1.ADVANTAGES

- CE compliance

- Full downdraft airflow

- High performance fan units

- High efficiency heat unit

- High ease of use

- Long lifespan

- Lower operating costs

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | IT-SUPER-1101 painting booth |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

| Internal dimensions | 7000 X 4000 X 2800mm (L X W X H) |

| External dimensions | 7110 X 5760 X 3810mm (L X W X H) |

| Airflow | Full Downdraft |

| Plenum (height) | 600mm |

| Extraction | Through 350mm high raised basement |

| Extraction area | 28m2 |

| Grids carrying capacity | 900kg/wheel |

| Entrance door | 3400x2700mm (WxH), 1 set |

| Service door | 800x2000mm(WxH), 1 set |

| Walls | 50mm rock wool walls |

| Ceiling lights (LED) | 8 sets, each 6 X 18W, 864W total |

| Sidewall lights (LED) | 8 sets, each 4 X 18W, 576W total |

| Brightness | >1,500LUX |

| Filters | Bag filter, high efficiency ceiling filter, floor filter, exhaust filter |

| Intake/Exhaust unit | Direct-type turbine fan, 2x11KW, SIEMENS motor |

| Air volume | 35,000m3/h |

| Empty loaded air speed | 0.35m/s |

| Heats | 315kw heat exchanger, RIELLO gas burner RS5D |

| Maximum working temperature | 80ºC |

| Controls | CE standard control box |

| Inverter | SCHNEIDER inverter |

| Rated power | 28KW |

- Generally considered as the best booth for auto refinishers, IT-SUPER-1101 downdraft painting booth has plenum across the roof to offer evenly disperse air movement with minimal turbulence in a vertical direction.

- It possesses air volume as big as 35,000m3/h, and velocity at 0.35m/s, fully in conformity with requirements of using water-based paints.

- The IT-1101 painting booth model is also equipped with SCHNEIDER inverter, regulating the frequency of motors when preparation is performed inside, which saves more than 30% energy consumption over the course of one year.

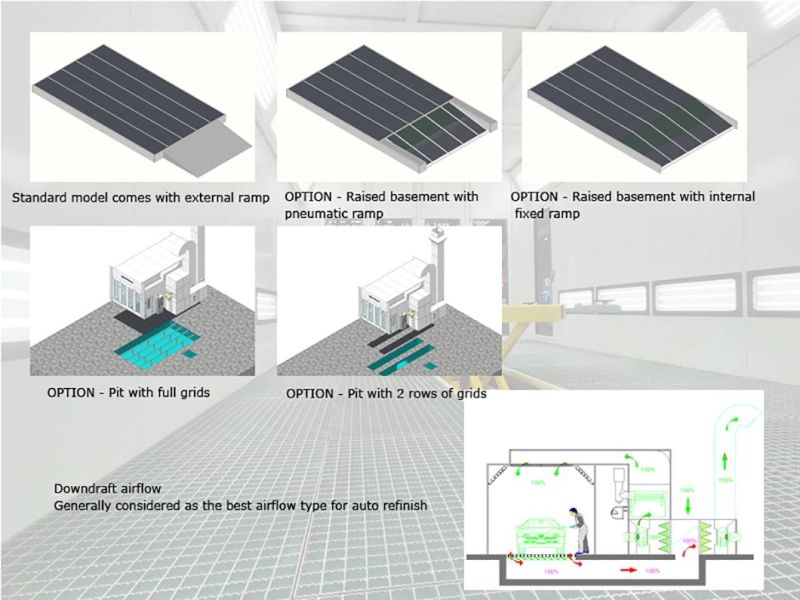

AIRFLOW & BOOTH STRUCTURE

The booth comes with downdraft airflow, 600mm top plenum and 350mm raised metal basement for extraction.

OPTION

The basement can be adapted to suit specific installation site.

- Metal basement sunken in the ground (concrete work required)

- Pit with full grids for extraction (concrete work required)

- Pit with two rows of grids for extraction (concrete work required)

- Raised metal basement with internal pneumatic ramp (no concrete work)

ENTRANCE DOOR & LIGHTS

- Wide opening entrance door

- Premium angled ceiling and vertical sidewall lights, >1,500lux

AIR HANDLING UNIT

- Efficient low noise fan unit

- Cylinder-drive conversion damper between spraying and baking phase

- 315KW heat exchanger, RIELLO gas burner RS5D (two stage)

OPTION

- RIELLO diesel burner RL34-2 (two stage)

- Direct gas fired heating system

CONTROL

- Control system full complies with European regulations

- SCHNEIDER inverter brings over 30% energy savings

UPGRADE

- Innovative touch screen control

FILTERS

| Item | Specification |

| Pre-filter | Bag filter |

| Ceiling filter | High efficiency F5 grade filter |

| Floor filter | Fiberglass paint arrestor filter |

| Extract filter | Activated carbon filter |

FAQQ: What is the required internal height of the building where the booth is to be installed?A: If you take 1101 model with raised metal basement, the internal height of the building should be at least 3900mm.

You can send your workshop dimensions or layout through, Infitech professional technician will integrate the booth design with your workshop. When required, we customize the booth to suit the workshop, and advise you on how to make full use of your workshop space.

Q: What is the payment terms?A: Usually, Infitech accepts 50% deposit upon order confirmation by T/T, and balance before shipment. For other payment terms, please contact Infitech sales engineer for more details.

Q: What is the production lead time?A: 20 days after receiving the advance payment.

Q: How many painting booths can fit into one container?A: For standard painting booth model 1101 (with raised basement), 1x40HQ container can load 1 set only. And 2 sets can be loaded in 1x40HQ+1X20GP containers based on separate packaging for each set of painting booth.

After loading 1 set in a big container, there is still space left inside. We will advise the space, so if you would like to add other items, such as spare filters, we can ship them together to avoid waste of shipping space.

Q: How can I install the spray booth?A: Usually, you will be provided with installation drawings and electric schematic together with detailed installation steps to help guide the installation. Infitech sales engineer keeps close contact with you during the assembly process, and he is ready to answer your questions in a timely manner.

Infitech can also send engineer over to offer installation guidance service at your special requests. Please talk to Infitech sales engineer to find more details.

Q: What is the warranty?A: Infitech offers 2-year warranty for painting booths except consumables.

Q: How to maintain the painting booths?A: You will be provided with maintenance instructions, according to which you can prepare the maintenance schedule and carry out regular maintenance.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23