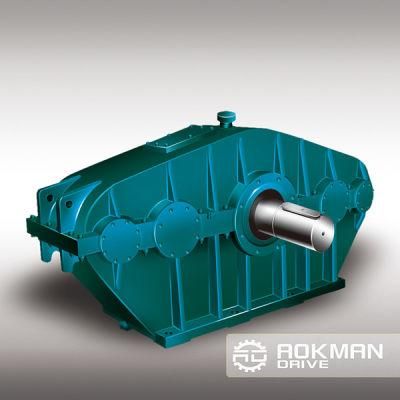

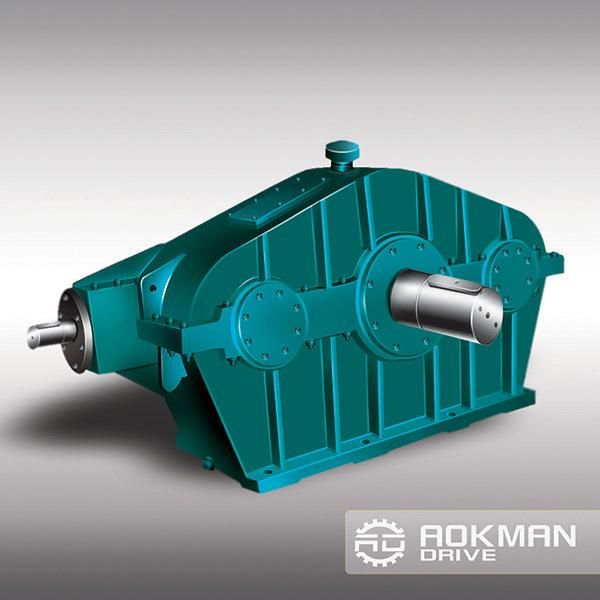

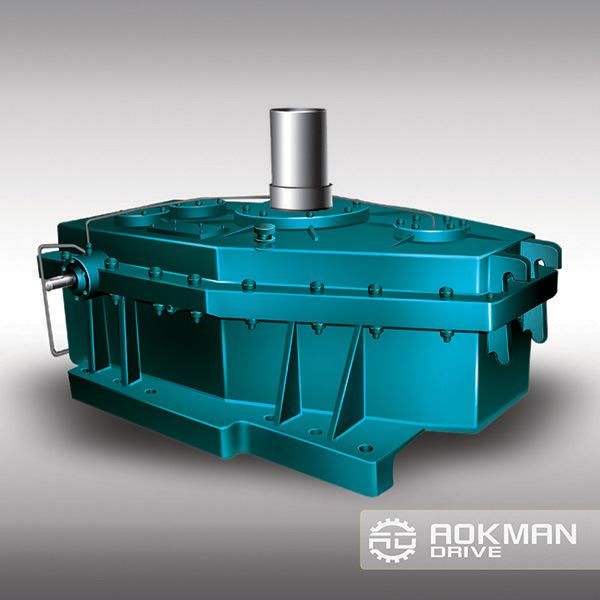

Cast Iron Three Rings Hardened Reducer Made in China

Shinylink (Shanghai) Industrial Inc. / 2022-06-27

- Application:Machinery, Industry

- Hardness:Hardened

- Installation:Horizontal Type

- Gear Shape:Cylindrical Gear

- Type:Gear Reducer

- Single Stage Ratio:11-99

=== Base Info ===

- Model NO.:Three Ring Reducer

- Two Stage Ratio:up to 9801

- Parameters:Customizable

- Voltage:220V, 380V, 440V

- Color:as Your Requested

- Material:Cast Iron

- Manufacturing Method:Forging Gear

- Toothed Portion Shape:Curved Gear

- Changes Way:Stepped

- Transport Package:Wooden Case

- Specification:ISO

- Trademark:AOKMAN DRIVE

- Origin:China

- HS Code:8483409000

- Production Capacity:5000PCS,Year

=== Description ===

Basic Info.

Model NO. Three Ring Reducer Two Stage Ratio up to 9801 Parameters Customizable Voltage 220V, 380V, 440V Color as Your Requested Material Cast Iron Manufacturing Method Forging Gear Toothed Portion Shape Curved Gear Changes Way Stepped Transport Package Wooden Case Specification ISO Trademark AOKMAN DRIVE Origin China HS Code 8483409000 Production Capacity 5000PCS/YearProduct Description

Cast Iron Three Rings Hardened Reducer Made in China1. BriefThree Rings Reducer(Tricyclic Reducer) is an advanced transmission machinery, it can be widely used in many fields: mining, metallurgy, petroleum, chemical, rubber and plastics, engineering, lifting, transport, and light industry, and it also can be as an alternative to the planetary gearbox, cycloidal reducer, multi-stage cylindrical gearbox and worm gearbox.

2. Product Characteristics

(1) Carrying capacity, long life, 9-18 pairs of teeth simultaneously into engagement zone, can withstand 2.47 times the output torque 938KNm.

(2) Transmission ratio, grading intensive, unipolar 11-99, two-stage up to 9801 in steps of about 1.1 times.

(3) Smooth operation, noise less than 78db, the vibration amplitude is less than 0.025MM.

(4) Compact structure, small size, light weight, smaller than conventional cylindrical gear reducer.

(5) Easy assembly and disassembly and repair, parallel shaft, less wearing parts and easy to change.

(6) Broad applicability, can be made horizontal, vertical, flange connection and combined transmission and other structures, the device can also be configured as a dedicated non-standard transmission, with multi-shaft, for multi-motor synchronous drive or drive control device assembly type and derived series range.

| center distance (mm) | 112-800 |

| ratio(i) | 1.25~500 |

| out-put torque(n.m) | 4130-600000 |

| voltage | 220v, 380v, 440v |

| color | as your request |

3. Applications

Multiple industries, such as: mining, metallurgy, petroleum, chemical, rubber and plastics, engineering, lifting, transport, and light industry, etc.

4. Dimensions

Customization according to the application.

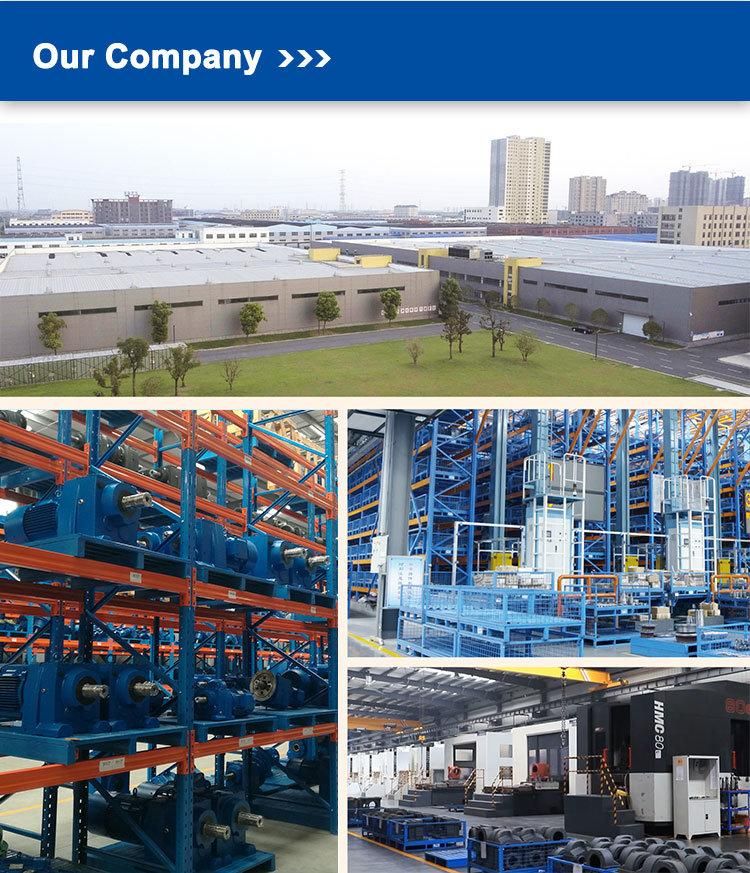

Our company :

AOKMAN® was founded in 1982, which has more than 36 years in R & D and manufacturing of gearboxes, gears, shaft, motor and spare parts.

We can offer the proper solution for uncountable applications. Our products are widely used in the ranges of metallurgical, steel, mining, pulp and paper, sugar and alcohol market and various other types of machines with a strong presence in the international market.

AOKMAN® has become a reliable supplier, able to supply high quality gearboxes.With 36 years experience, we assure you the utmost reliability and security for both product and services.

Customer visiting:

FAQ:

1.Q:What kinds of gearbox can you produce for us?

A:Main products of our company: UDL series speed variator,RV series worm gear reducer, ATA series shaft mounted gearbox, X,B series gear reducer,

P series planetary gearbox and R, S, K, and F series helical-tooth reducer, more

than one hundred models and thousands of specifications

2.Q:Can you make as per custom drawing?

A: Yes, we offer customized service for customers.

3.Q:What is your terms of payment ?

A: 30% Advance payment by T/T after signing the contract.70% before delivery

4.Q:What is your MOQ?

A: 1 Set

If you have any demand for our products please feel free to contact me

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23