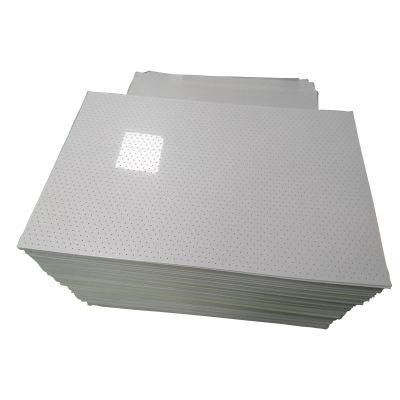

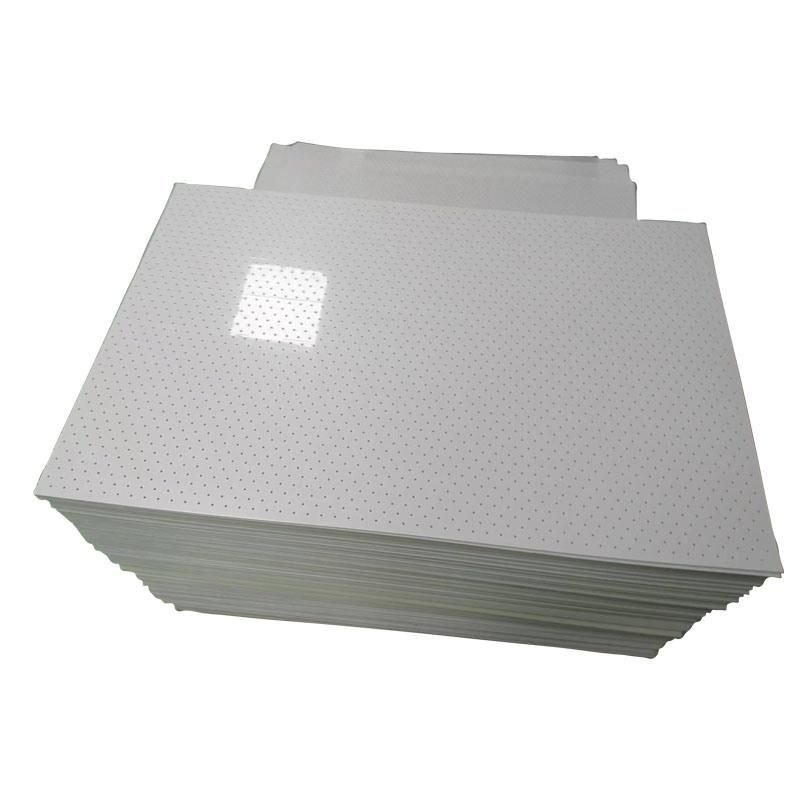

Moldable Splinting Thermoplastic Sheet Othopedic Polymer Splint

Yuyao Foison Plastic Products Factory / 2022-06-23

- Material:Plastic

- Quality Guarantee Period:Two Years

- Logo Printing:Without Logo Printing

- Transport Package:Carton Box

- Specification:600*900mm ,34′′*36′′

- Trademark:Aojianyi

=== Base Info ===

- Model NO.:AJY-KB

- Origin:China

- HS Code:3920109090

- Production Capacity:1000PCS,Week

=== Description ===

Basic Info.

Model NO. AJY-KB Origin China HS Code 3920109090 Production Capacity 1000PCS/WeekProduct Description

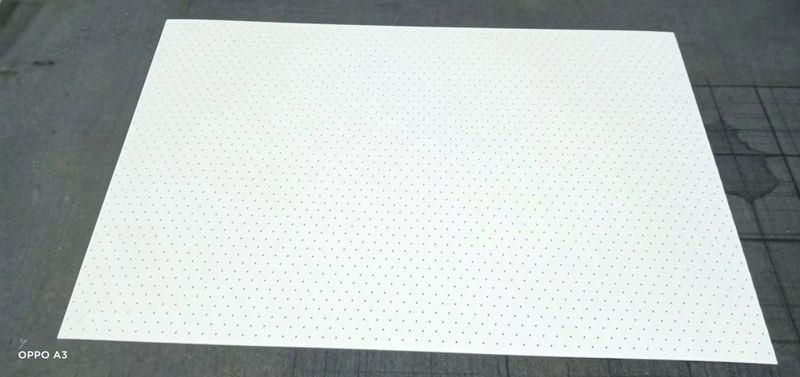

Moldable Splinting Thermoplastic Sheet Othopedic Polymer SplintSize: 600*900mm

Perforation: 0%, 5%, 10%, 19%, 22%, customized

Usage: Immobilization & sterilization

Application: Orthopedic / rehabilitation

Users: OT/ PT

Certification: CE, SGS

Application Scope

- Used for the fixation of fractures, dislocated joints, ligament soft tissue damage, and tendon damage.

- Used for the fixation of soft tissues such as joint ligaments, nerves, and tendon injuries in post surgery.

- Used for the fixation during conservative treatment or after lesions removal, such as: bone, joint tuberculosis, myelitis, purulent arthritis, primary bone tumor metastasis, etc.

5. Used for the external fixation after burns and other cosmetic surgery.

6. Used for the production of rehabilitation splint and orthosis.

How works?

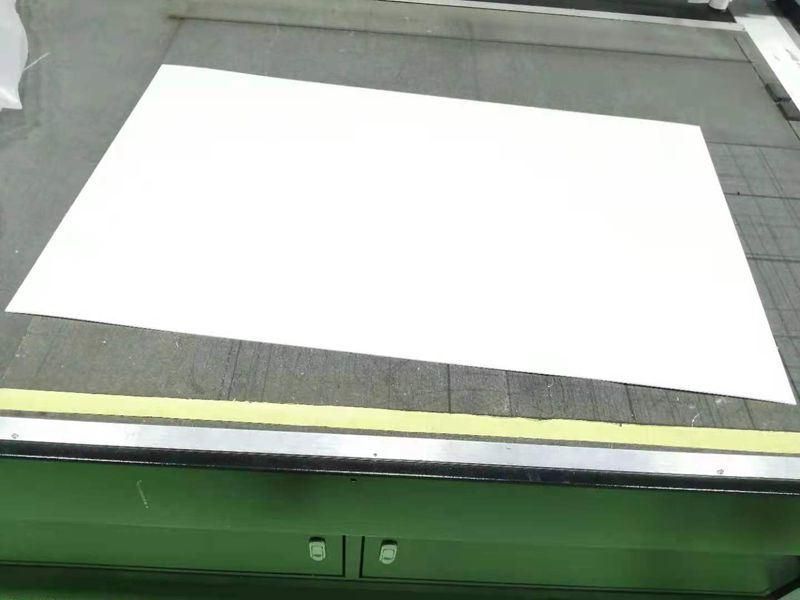

- Prepare the materials and tools, set the water bath to 65-70°.

3. Put the splint sheet into the 65-70° hot water for 2-3 minutes, it could become soft. Remove it to the worktable, make it dry.

4. Place the splint sheet to the user's body part, mould it to the right shape accordingly. Turn outwards the hard edges, thus to prevent hurts. Adjust the splint to the right angle.

5. Tubular splint could be shaped with two sheets combined together.

6. If a molding work is failed, it can be soften into the hot water and reshape again. Especially used for those who need multiple moldings due to the disappearance of edema.

7. After the splint becomes stiff, adjust the edges to the right status. (Paddings or trimms could be used on the bone protrusions and joints, thus to avoid any crushings)

8. Velcro and elastic bandages are used to fasten the splints on the right position.

9. It can expose the designated wound site and avoid inflammation and ulcer caused by covering.

Application Field:

- Orthopedics

- Rehabilitation hospital

- Burn department

- Aesthetic and Reconstructive Plastic Surgery

- ENT department

- First Aid & Emergency

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23