OEM/ODM Gear /Gear Ring/ Gear Shaft

XIAMEN HONGJU UNITED TECHNOLOGY CO., LTD. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car

- Hardness:Hardened

- Manufacturing Method:Cast,Cut,Rolling,Sintered Gear

- Toothed Portion Shape:Spur,Bevel,Curved,Doublehlical Gear

- Material:Stainless Steel

- Type:Circular,Wormand Worm Wheel,Bevel,Non-Circular,Rac

=== Base Info ===

- Size:According to Customer Requirements

- Quality:According to Customer Requirements

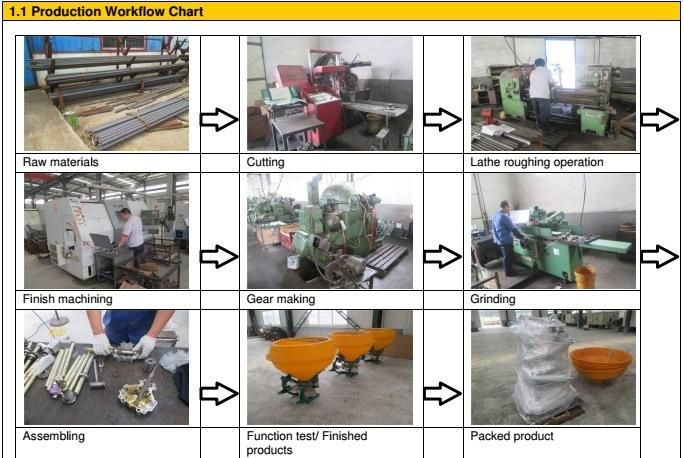

- Manipulate Way:Semi-Automatic Manipulation

- Changes Way:Stepless

- Transport Package:Wooden

- Specification:Many Size

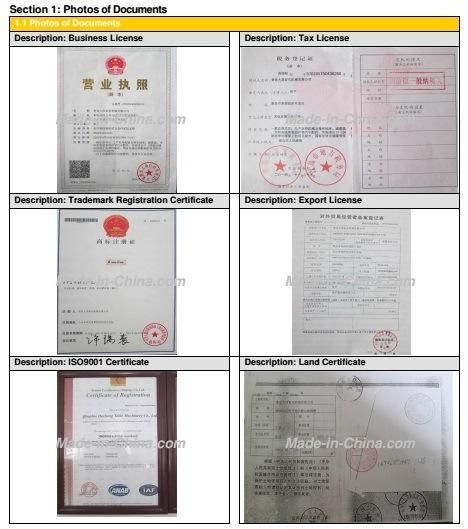

- Origin:Qingdao

- Production Capacity:100000PCS,Month

=== Description ===

Material

FAQ:How to order?

Advantages:

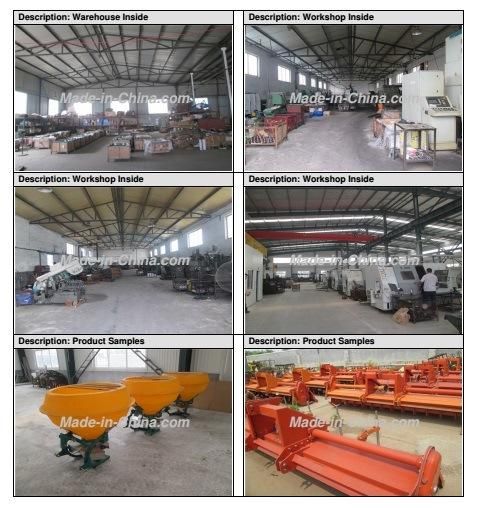

1. Professional gears manufacturer

2.Experienced in Cooperate with big Companies

3. Professional gears Engineering Capability

4.Stable gears Quality

5.Reasonable gears Prices

6.Small gears Orders Accepted

7.Continuous gears quality improvements

8. High gears quality Performance

9.Short gears lead time and shipment

10.Professional gears service

We can provide with sample for quality and function testing.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23