Sand Casting Ductile Iron Farm Machinery Tractor Front Parts Wheel Hub

WuHan LanYuan Protective Co., Ltd. / 2022-06-24

- Warranty:5 Years

- Material:Iron

- Type:Wheel Hub

- Drive Wheel:FWD

- Wheel Hub Diameter:<16"

- Finishing:Paint

=== Base Info ===

- Wheel Accessories:Hub Ring

- Spoke Type:Equal Diameter Spoke

- Certification:ISO

- Wheel Hub Brand:Himile

- Transport Package:Non-Solid Wood Packing Case

- Specification:ductile iron

- Trademark:Himile

- Origin:Weifang China

- HS Code:8707701000

- Production Capacity:10000 Pieces,

=== Description ===

Physical and Mechanical Properties

3

About Quality

We insist that the survival of the company should depend on the products quality i continuous improvement, without which we cannot survive for long.

Our product quality control system

Quality control involves the inspection and control of incoming materials, production process and finished products.

1 Firstly, metallurgical microscope analysis is performed on randomly sampled incoming materials to ensure that the chemical composition meets the production requirements.

2 Then, during the production process, there are QC personnel to conduct timely spot checks to ensure that the product is free of defects during the manufacturing process and to coordinate and handling of any abnormal quality issues that may arise.

3 The final step in the production process is a magnetic particle detector for metal parts to detect hidden cracks or other defects.

4 All the finished metal parts is sampled in proportion and sent to the laboratory for various mechanical property tests and dimensional measurements, and the surface quality is manually 100% inspected.

The relevant testing equipment pictures are as follows:

4

Quality management system of the organization.

We strictly carry out system management in accordance with iso9001 and ts16949 quality standards. And 5S lean production management is implemented on the production site.

The certification we have passed and the pictures of production management site are as follows:

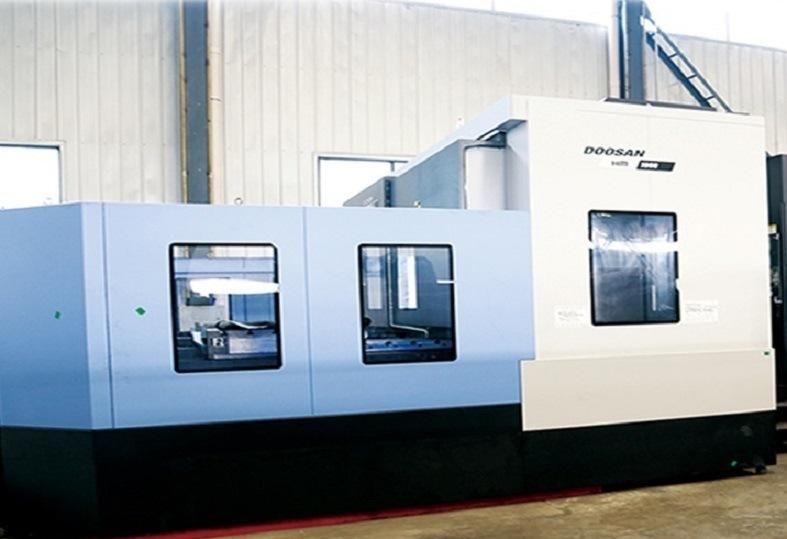

Production Equipments Pictures:

5

Our Advantages:

1 We have a complete production process and equipment research and development capabilities for non-ferrous metal forming. Over 25 years of production experience of forging equipment and casting equipment make us own deep level understanding and operating of all equipments' performance and running.

2 Our parent company, Himile Group, is a world-renowned high-end machinery manufacturing enterprise with more than 30 domestic subsidiaries and branches. The sales volume of four products ranks No1 nationwide and even worldwide, providing us with a strong technical and financial support.

3 One-third of over 300 staff are technical technical R&D members, ensuring the continuous technical innovation and the sustainable development of our company.

4 Our company implements the employee stock ownership system of company shares Increasing members' sense of responsibility, creativity and work motivation.

5 The company is a model enterprise in the region of low-carbon environmental protection, and energy saving and emission reduction in reduction.

6 Unique company culture, and the regular rotation of individual work position give full play to the potential of talents and provide strong vitality for the development of the company.

Workshop Outward View Pictures:

6

Our order execution process

1 The Sales department accepts drawings or samples from customers and sends them to the technical department.

2 The technical department confirms the material consumption and manufacturing process.

3 Production department, Purchasing department, Finance department, coordinate to account for the cost.

4 The Sales department provides the customer with a quotation for the product.

5 After the price and delivery date are determined, both parties will sign the drawing through the Sales department as the final confirmation.

6 The customer prepays the mold fee, Sales department inform Financial department about the deposit condition and Production department pre-arranged production schedule.

7 Preproduction sample is sent to customer for confirmation,

8 After the sample confirmed, the customer pays the deposit. small batch orders are handled by Sales department.

9 After the small batch is confirmed, the large batch order is put into production and is organized by Production department.

10 The Sales department is responsible for the delivery of products and the customer's receipt when the production is finished.

11 All the documents provided by the Sale department should be handed to the Finance department after the products' departure, and confirms the payment . when the contract execution is completed, it should be put on record by the Finance department and file it

8

FAQ

1.

Q: Are you a trading company or a manufacturer?

A: Obviously we are a manufacturer of forging products, casting products and also have a high level of machining capabilities.

2.

Q: What series products do your have?

A: We are mainly engaged in forming processing of non-ferrous metals, including processing by casting , forging and machining. As you know, such machinery parts can be observed in various industries of equipment manufacturing.

3

Q: Do you provide samples? is it free?

A: Yes, we commonly provide samples according to the traditional practice, but we also need customers to provide a freight pay-by-account number to show mutual sincerity of cooperation.

4

Q: What is your minimum order quantity?

A: Yes, we require all international orders to have an minimum order quantity. The quantity is up to the exact products feature or property such as the material, weight, construction etc.

5

Q: What is the lead time?

A: Generally our forging products and casting products need to make new dies or molds, the time of making new dies or molds and samples within 30-45 days, and the large batch production time within 30-45 days. it's also according to the parts structural complexity and quantity.

6

Q: What kinds of payment methods do you accept?

A: You can make the payment by T/T or L/C. 30% deposit in advance, 70% balance against the copy of B/L.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23