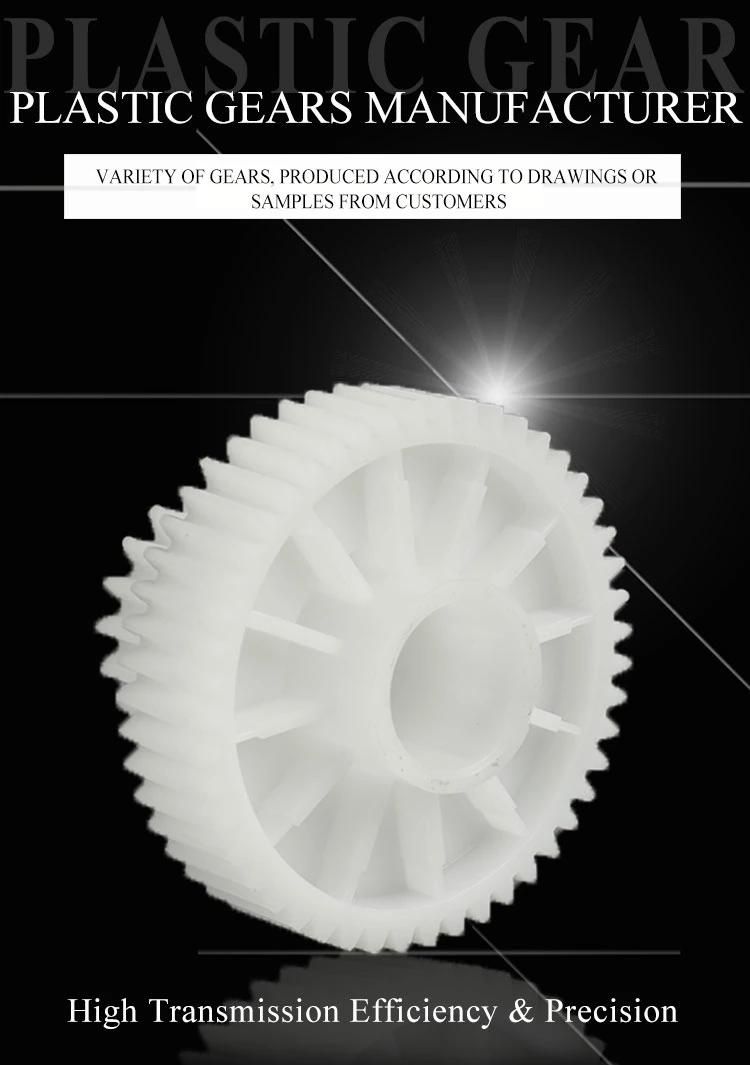

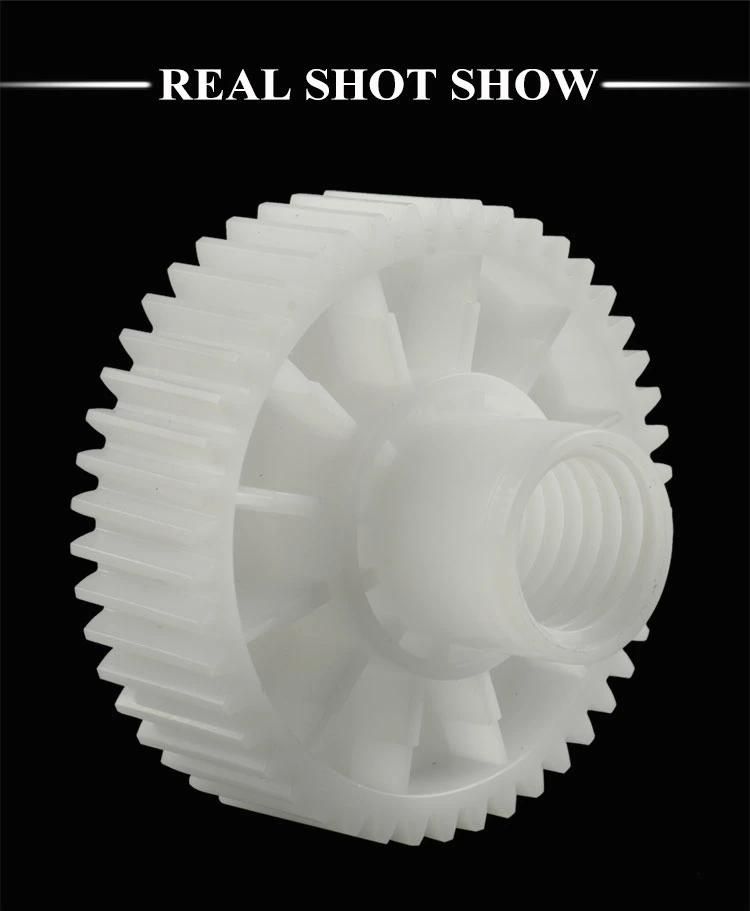

Reduction Machine Drive Involute Precision Transmission Plastic Injection Helical Gear

Ningbo Ezfocus Co., Ltd. / 2022-06-27

- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Printing Machinery

- Hardness:Soft Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Injection Plastic Gear

- Toothed Portion Shape:Double Helical Gear

- Material:POM PA66 Nylon Peek PP PA66 and Glass Fibre

=== Base Info ===

- Model NO.:QC-049-02

- Type:Circular Gear

- Module:0.1 .02, 0.4, 0.5 1, 1.5, 0.75,0.8,2 3 etc

- Pressure Angle:20 Degree

- Teeth Shape:Transmission Gear

- Pinion:Pinion Gear

- Cog Wheel:Gear Wheel

- Dimension Tolerances:-,+0.01mm

- Reduction:Reduction Gear

- Noise:Low Noises

- Pitch Diameter:OEM Gears

- Silence:40 Nto 60 Decibels

- Precision:-,+0.02mm

- Lubricating:Self-Lubricating

- Standard:Agma-08 JIS DIN

- Drawings:2D or 3D Drawings Step Igs

- Teeth Type:Helical Teeth Gear

- Transport Package:PP Bags and Cartons

- Specification:20 teeth 30 teeth 40 teeth 60 teeth

- Trademark:Q&c and OEM ODM

- Origin:Dongguan China

- HS Code:84834090

- Production Capacity:1000000,Month

=== Description ===

Basic Info.

Model NO. QC-049-02 Type Circular Gear Module 0.1 .02, 0.4, 0.5 1, 1.5, 0.75,0.8,2 3 etc Pressure Angle 20 Degree Teeth Shape Transmission Gear Pinion Pinion Gear Cog Wheel Gear Wheel Dimension Tolerances -/+0.01mm Reduction Reduction Gear Noise Low Noises Pitch Diameter OEM Gears Silence 40 Nto 60 Decibels Precision -/+0.02mm Lubricating Self-Lubricating Standard Agma-08 JIS DIN Drawings 2D or 3D Drawings Step Igs Teeth Type Helical Teeth Gear Transport Package PP Bags and Cartons Specification 20 teeth 30 teeth 40 teeth 60 teeth Trademark Q&c and OEM ODM Origin Dongguan China HS Code 84834090 Production Capacity 1000000/MonthProduct Description

Reduction Machine Drive Involute Precision Transmission Plastic injection Helical Gear| Item | Customized machined injection plastic gears |

| Craft Process | Plastic Injection or CNC machining |

| Plastic Granules | UL, FDA, RoHS etc. |

| Quality Control | ISO9001 and ISO14001 |

| Molds Material | S316,H13,718,738,P20,H13,420SS |

| Mold Life | 300,000 shots or 1,000,000 shots or more |

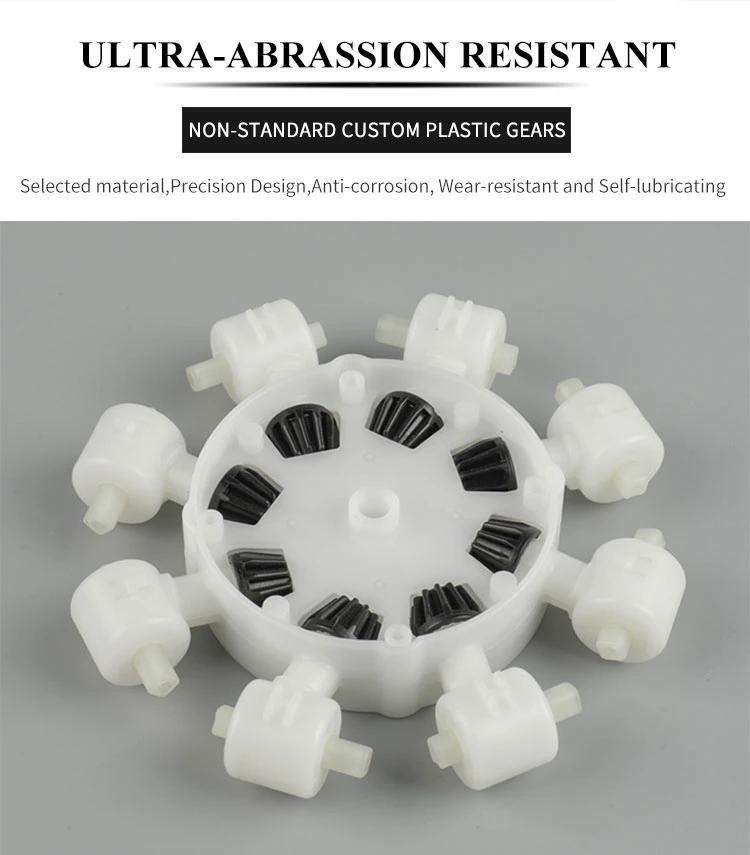

| Mold Cavity | Single-cavity or two cavities or Multi-cavity |

| Material | Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc. |

| Molds cavity Hardness | 60 to 90 H.R.C |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. |

| Size Tolerance | ±0.05mm or more precise |

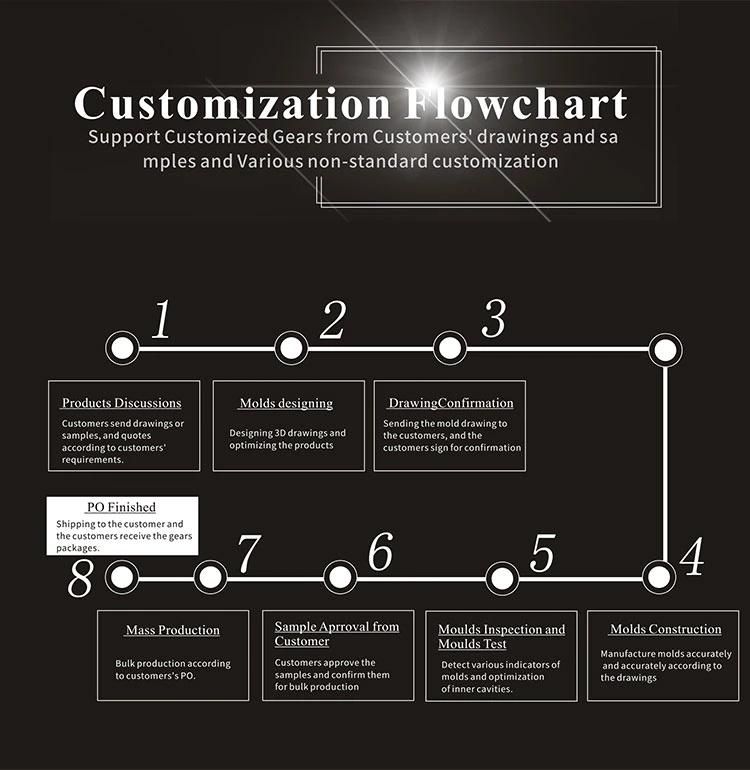

| Work Flow chart | Step1: Make tooling firstly and usual need 2~~3 weeks. Step2: Produce and confirm samples. Step3: One week for mass production usual. |

| Samples confirmation and approval | Free samples shipped for confirmation and shipping cost paid by customers |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer's requirements. |

| Delivery Time | Total takes 2~~4weeks usual |

| Payment Terms | PAYPAL, T/T, Western Union |

| Shipping | Usual FEDEX, UPS, DHL, TNT, EMS or base on customer's requirement. |

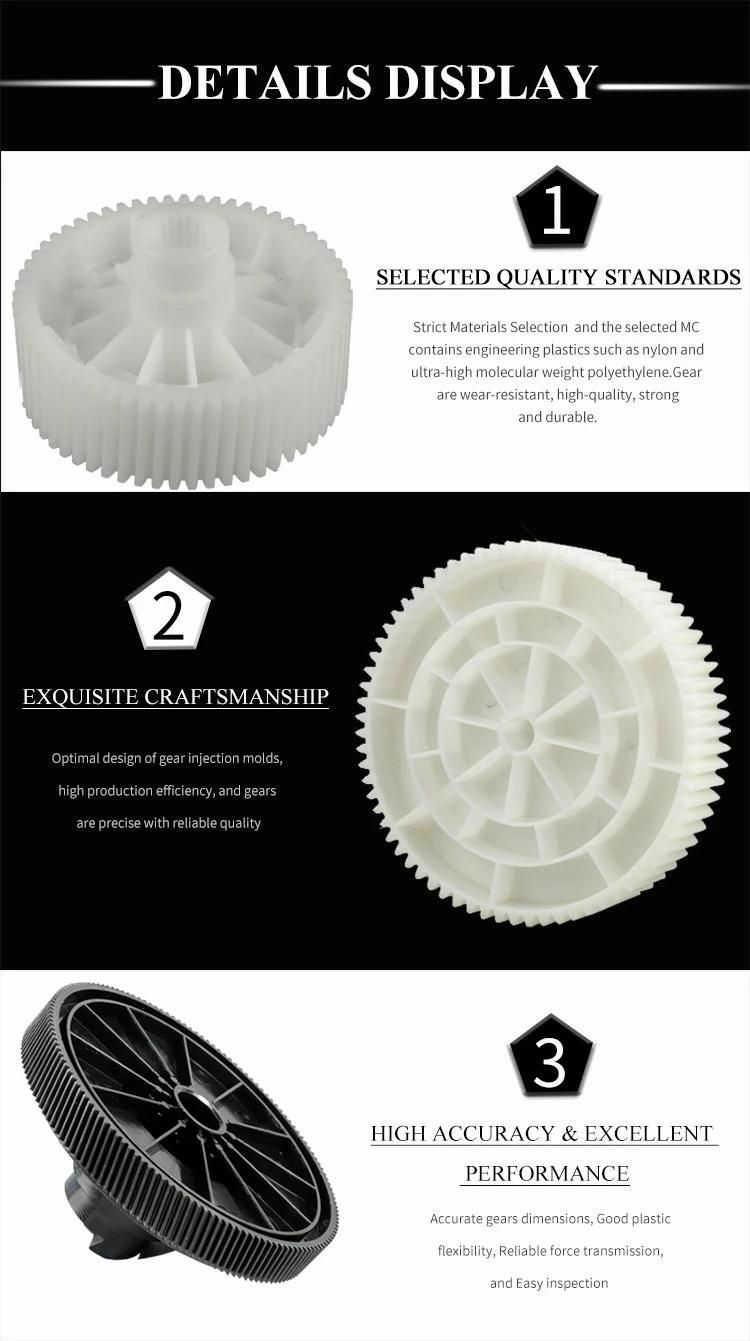

Our Company Features

1) Gears OEM service as per clients' drawings or samples, with in-house tooling design & fabricating or manufacturing.

2) Professional gears engineering capability: gears design, optimization and performance analysis

3) Gears manufacturing capability range: DIN 3960 class 8 to 4, ISO, AGMA 2000 class 10-15, JIS 1702-1703 class.

4) Gears packing: packaging method according to customer's requirement

5) In-time delivery capability

Primary Competitive Advantages

1. Professional gears manufacturer

2.Experienced in Cooperate with big Companies

3. Professional gears Engineering Capability

4.Stable gears Quality

5.Reasonable gears Prices

6.Small gears Orders Accepted

7.Continuous gears quality improvements

8. High gears quality Performance

9.Short gears lead time and shipment

10.Professional gears service

FAQ

Q1: What kind of gears can you supply?

1. High precision plastic and metal gears with low noise, stable transmission

2. Plastic gear Injection mould

3. Gearbox and gearbox assembly

Q2: What is your advantage?

Professional gear and gearbox manufacturer in China Mainland, Established in the year of 2008. One-stop service from gear R&D, gear design, gear mould build, gear manufacturing, and gearbox assembly

We equipped Japan original HAMAI N60 CNC gear hobbing machines, Switzerland original Agie Charmilles C Axis EDM , MAKINO EDM, WEDM-LS, and Osaka JIS test center, Osaka gear mesh tester, concentricity tester, CMM, noise test room etc. Advanced facilities provide dedicated service to customers.

Q3: Why Choose Q&C in China?

1. Professional R&D Team: provide most suitable customize transmission solutions as per application and customer's requirement.

2. Excellent Quality Control: Stick Quality control system, 100% inspection or test before shipment.

3. Excellent After Sales Tracking System: Offer Each Photos, Delivery and Marketing Information sharing.

4. Quick response: sales provide quick response within 24 hours.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23