The Hottest Changers Car Machine Automatic Tire Changer

Tenda Enterprise Holdings Co., Limited / 2022-06-23

- After-sales Service:Videocall, Online&Face to Face Training Acceptable

- Warranty:14 Months

- Structure:Vertical

- Power Source:Pneumatic

- Type:Simple Disassembly

- Automatic:Semi-Automatic

=== Base Info ===

- Model NO.:C9552R

- Standard:Standard

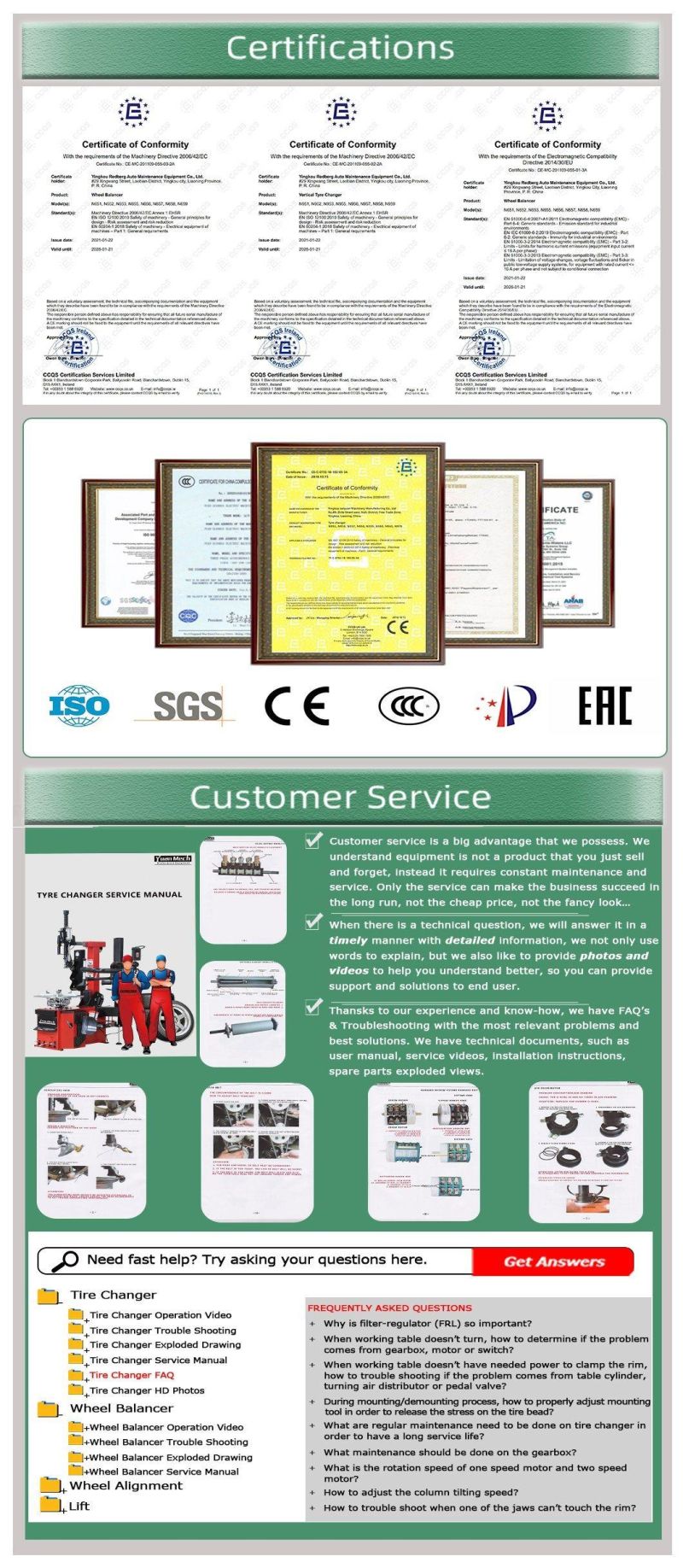

- Certification:CE

- Condition:New

- Product Name:Tyre Changing Equipment Tire Replacement Machine

- Working Pressure:8-10bar,117-145psi

- Outside Clamping:10-22"

- Inside Clamping:13-24"

- Max. Wheel Width:3-15"

- Max. Wheel Diameter:1040mm (41")

- Bead Breaker Force:2500kg

- Color:Customized Color Acceptable

- Machine Weight:N.W:245kg G.W:270kg

- Optional Specifications 1:Optional Different Kinds of Front Cover

- Optional Specifications 2:Optional Different Kinds of Pneumatic Locking

- Optional Specifications 3:Optional Different Kinds of Inflation Gun

- Optional Extra Accessory1:Motorcycle Adaptor

- Optional Extra Accessory2:Bead Blaster Function

- Optional Extra Accessory3:Leverless System

- Transport Package:Plywood

- Specification:1160*900*1050mm

- Trademark:YuanMech

- Origin:Yingkou, Liaoning, China

- HS Code:8479899990

- Production Capacity:3000PCS,Month

=== Description ===

1. What are regular maintenance need to be done on tire changer in order to have a long service life?

Periodically drain the water in FRL, add oil in FRL so it can protect pneumatic components. Regularly tighten the bolts and screws on working table. Also check mechanical play or clearance on demounting head, hex bar... Check the belt tension.

(Please contact us if you have more questions on this topic)

2. What are regular maintenance need to be done on tire changer in order to have a long service life?

Periodically drain the water in FRL, add oil in FRL so it can protect pneumatic components. Regularly tighten the bolts and screws on working table. Also check mechanical play or clearance on demounting head, hex bar... Check the belt tension.

(Please contact us if you have more questions on this topic)

3. When working table doesn't have needed power to clamp the rim, how to trouble shooting if the problem comes from table cylinder, turning air distributor or pedal valve?

When the cylinder not strong enough, there could be air leaking. The leaking could be on the covers or internal piston. There is a systematic method to trouble shoot, please contact us if you are interested in how to trouble shoot.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23