Customized Industrial Spray and Bake Cabin for Big Size Products

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Downdraft

- Heating Mode:Gas Heating

=== Base Info ===

- Paint Mist Treatment:Dry-type

- Condition:New

- Extraction:Through 800mm Deep Pit with Grids

- Carrying Capacity:900kg,Wheel

- Walls:60mm Thick Rock Wool Panels

- Lights:LED Lamps

- Illumination:>1,000lux

- Fan Units:Direct Drive Fan Units

- Heats:Direct Gas Fired Heating System

- Empty Loaded Air Speed:Over 0.25m,S

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:18, 000x6000x5500mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Paint Mist Treatment Dry-type Condition New Extraction Through 800mm Deep Pit with Grids Carrying Capacity 900kg/Wheel Walls 60mm Thick Rock Wool Panels Lights LED Lamps Illumination >1,000lux Fan Units Direct Drive Fan Units Heats Direct Gas Fired Heating System Empty Loaded Air Speed Over 0.25m/S Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 18, 000x6000x5500mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

Customized Industrial Spray and Bake Cabin for Big Size Products1.FEATURES

The paint and bake cabin comes with large capacity allowing for painting and baking big size products. It is specially designed with overhead conveyor chain system and floor conveyor system, facilitating the transfer of heavy parts.

Infitech specializes in custom spray booth projects, providing customers with optimal solutions at competitive pricing.

2.DETAILS

- Airflow: downdraft

- Extraction: through 800mm deep pit with grids (carrying capacity: 900kg/wheel)

- Gantry structure (made of square tubes) for reinforcing the strength of the cabin

- Walls: 60mm thick rock wool panels, 0.426mm thick substrate

- Lights: IP55 protection grade lighting fixtures, LED lamps, illumination>1,000lux

- Doors: Drive through manual entrance doors, with device to support the weight of the door panels

- Fan units: direct drive fan units

- Heats: direct gas fired heating system

- Empty loaded air speed is over 0.25m/s.

- With inverter control, energy-saving.

- Overhead conveyor system is integrated to the booth structure, ensuring spacious workspace and aesthetics.

- Floor conveyor chain for transfer of parts that cannot be suspended.

- Manual door in the middle for dividing the big size booth to 2 parts, allowing for two areas to work individually, increasing work flexibility and work efficiency.

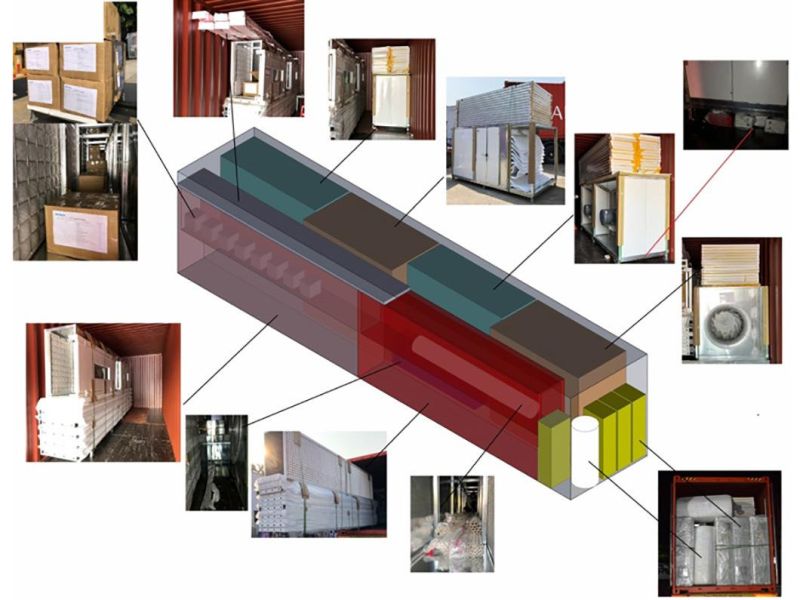

PACKAGING AND LOADING PHOTOS

FAQ

Q: What is the maximum working temperature of the paint and bake cabin?

A: 80ºC.

Q: The big size manual entrance door is very heavy. I would like to use electric entrance door for the paint and bake cabin.

A: That's okay. And we also recommend electric entrance doors.

Q: How long does it take to install this type of massive paint and bake cabin?

A: Approx. 30 working days by 3-4 people. However, the time might vary depending on different booth configurations.

Q: How to install the paint and bake cabin?

A: The paint and bake cabin is installed according to the steps below.

- Install the reinforced gantry structure

- Install the wall panels

- Install the entrance doors

- Install the ceiling panels

- Install the air handling unit

- Install the ducts

- Wiring

- Start-up

Q: How often should I replace the filters?

A: For pre-filter bag filters, they need to be replaced once every month; ceiling filters (F5 grade filters) are replaced every 3 months; floor filters (fiberglass filters) are replaced every 15 days. The maintenance intervals are for reference only. They change subject to the actual working condition of the paint and bake cabin.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23