Retail Shop Design Convenience Store Supermarket Cash Checkout Counter Stand with Belt

Anhui Innovo Bochen Machinery Manufacturing Co., Ltd. / 2022-06-28

- Material:Wood

- Usage:Supermarket, Convenient Store, Store, Drug Store, Hotel, Restaurant, Bank

- Condition:New

- Customized:Customized

- Feature:Good Quality, Eco-Friendly, Durable.

- Logo:Customized; Silk-Screening, UV, Engraving....

=== Base Info ===

- Model NO.:GND-WD-SMR125

- Production Lead Time:3-15 Days for Samples; 25-40 Days for Production.

- Shipment:Ocean Shipping, Airlift and Express.

- MOQ:Small Quantity Accepted.

- OEM/ODM:Accepted.

- Transport Package:as Your Request.

- Specification:Customized

- Trademark:N,A

- Origin:China

- HS Code:9403609990

- Production Capacity:200000PCS,Year

=== Description ===

Overview

Product DescriptionCompany & Bespoke Service

GOnDO Displays (Xiamen) Industry & Trade Co., Ltd. is a manufacturer & supplier of custom retail store displays and fixtures in the Point-of-Purchase industry, with professional retail display solution services for more than 10 years, in Xiamen China. GOnDo Displays techniques and products include displays in wooden (hardwood, MDF, PB, plywood), metal (iron, stainless steel, aluminium ...), plastic (acrylic/PMMA/Plexiglass/Perspex/Crystal, PVC, PETG, PET, PC, ABS ...), tempered glass, cardboard, stone, and many other materials, with various printing options. For more infos about our company, please kindly visit our website or contact us for details. We warmly and sincerely welcome you to visit our factory and expect to establish a long-term relationship with you. Any inquiry of our products, please do not hesitate to send us for quotation.

Customize IT

Whether in retail environments, trade shows, galleries or another setting, when you're looking for a way to display your products or materials that will get customers' attention, you want your displays to stand out. Lightweight and affordable, our displays are the ideal solution for attractively showcasing products at your shop, in your office, in a store window, at a marketing event and more.

Backed by a commitment to premium quality and customer satisfaction, GOnDo Displays is proud to be your resource for display items anywhere you go. Our company specializes in creating retail displays that boost your business sales and profits - from point-of-purchase (POP) displays to sign holders to ballot boxes to display stands. Through clear, simple displays fitted to your items, we help make your products, literature and marketing materials to attract your desired audience. What's more, all of our displays are made at our state-of-the-art facility, utilizing direct material sourcing and the latest in manufacturing technology. Shop our expansive product selection to learn more! Count on us to provide fast turnaround that gets your goods displayed as quickly as possible. Enjoy custom designs, great prices and capabilities to scale up to even the largest orders.

Call us and connect to our design team, just drop us an email, so we can help you create one-of-a-kind retail displays, trade show exhibits, pamphlet displays and more.

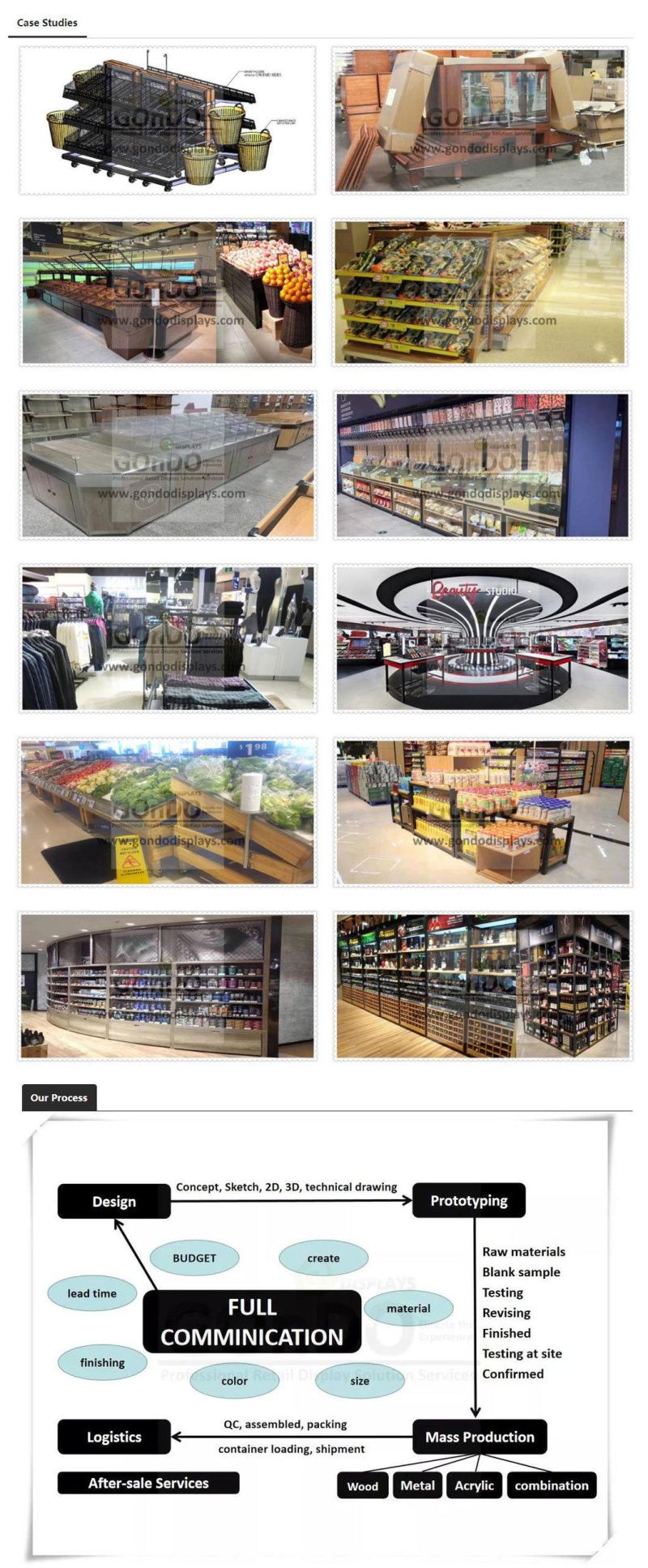

Design IT

Development, Prototyping, Production, Logistics, Installation and After-sales service! No matter how complicated the project is, we could always provide you with a perfect solution with our incomparable professional knowledge. Whether you come to us with your basic thoughts or with elaborate concepts and drawings, you could always trust our team to turn them into efficient and reliable retailing projects with competitive prices and higher quality. We provide professional display solution from sketch, 3D, 2D and sample for our customers and start quickly costing, prototype and bulk production. While some clients want unique solutions to meet their needs, we find many of our clients are looking for a more standard, modular solution. This can be something "off the shelf", perhaps with some minor alterations to meet their needs. Our in-house design team utilizes the latest computer-aided design and modeling technology to provide substance and form to our customers' ideas. Developed from a unique design or concept, a fully functional, three-dimensional model is then rendered for customer approval. The outcome is achieved by our capable engineers, who specialize in a particular area of production to provide expert knowledge for accurate drawings. Our engineers use the advanced "Solid Works", "Auto CAD" and "Pro Engineer" computer programs to provide customers with a 2D or 3D perspective of developing products. This technology makes the design process faster, easier and less costly by perfecting the structural concept prior to the production of the prototype. After sample done and before sent out, we assemble the samples to confirm the final dimension and material.

Printing

Printing on Wood & Metal & Acrylic & Glass & Stone by GOnDo Displays

A wealth of experience

GOnDo Displays has been offering a printing service for retail displays according to the customer requirement. We provides all kinds of logo printing methods, such as laser cutting, laser marking, silk-screen printing, Inkjet printing, Rotary printing, UV printing, sticker label, etc.. This opens up a huge range of options. The only limit is your imagination!

Our acrylic displays, due to the transparency and lightweight, almost our customers used for advertising to attract the customers' attention. Silk-screening and UV printing are 2 major printing for acrylic products. We print and bend acrylic steps, risers, sign holders, brochure holders, photo frames, jewelry displays ...

If you would like GOnDo Displays to print your logo, pattern or picture (or any other image), just drop us an email. The higher resolution your artwork the better quality the end result. Printing prices depend on the quantity of items you require and the color and size of the image.

Small MOQ

GOnDo Displays' goal is to help you, as a business owner, fully furnish a store, trade show booth, or municipality at an affordable cost. We understand that managing a budget leaves no room for wasted merchandising expenses. Because of this, we offer small trial orders to get you what you need, when you need it. Small QTY is welcome and accepted. Ocean Shipping, Airlift and Express (EMS, UPS, DHL, TNT and FEDEX) shipments are all welcomed. We quote for you based on EXW, FOB, CFR, CIF, DDU, DDP trade terms accordingly. L/C, T/T, Paypal, Western Union payment term are accepted.

GOnDo Displays develops complete retail solutions while meeting your functionality and budget requirements. We work with a wide range of clients across the country, and create custom designs to help better the brand engagement and presence. Our exquisite manufacturing technique brings OEM/ODM designs into full play. We are specialized in bespoke store displays and fixtures. We offer and manufacture a full range of custom retail store displays and fixtures, including custom acrylic counter top displays, Eyewear and jewelry displays, brand signage, cosmetic makeup displays, clothing displays, glasses displays, point-of-purchase displays, Gondola, fruit and vegetable displays, bakery displays, displays for umbrella, watch, floral, clothes, shoes, bags, caps, arts and crafts, gifts, candy, electronic products, helmet, basketball, football, baseball, tobacco and liquor, mosaic, literature, coin, candle, DVD, ... and much more.

Our in-house design team utilizes the latest computer-aided design and modeling technology to provide substance and form to our customers' ideas. Developed from a unique design or concept, a fully functional, three-dimensional model is then rendered for customer approval. The outcome is achieved by our capable engineers, who specialize in a particular area of production to provide expert knowledge for accurate drawings. Our engineers use the advanced "Solid Works", "Auto CAD" and "Pro Engineer" computer programs to provide customers with a 2D or 3D perspective of developing products. This technology makes the design process faster, easier and less costly by perfecting the structural concept prior to the production of the prototype.

Laminate (MDF & PB & Plywood) & Hardwood (Solid Wood) Process

Gondo Displays' wood production facility utilizes some of the most advanced, labor-saving machinery available, allowing us to produce beautifully crafted fixtures at competitive prices for our customers. In order to create specialized items, we source materials that best match our customers' visual expectations and durability requirements.

Laminate (MDF & PB & Plywood) Production

(1) The materials include laminates, MDF board, HDF, particle board, plywood, honeycomb and slat wall. General thickness : 3mm, 6mm, 9mm, 12mm, 15mm, 16mm, 18mm and 25mm; if need thicker, remake by cold pressing machine.

(2) Laminating is done with cold pressing machine. Hot Pressing Machine is used to press veneer, to make the Melamine paper or other PU/PVC papers and base material joint together. The temperature needs to be about 200 degree. And it needs to use firewood to make the high temperature, but not just electricity. And also some conditions we need to use the Cold Pressing Machine. Its function is different from Hot Pressing Machine. It is used to make 2 or more base material joint together.

(3) From the cold press, the material flows to the vertical panel saw or sliding table saw for cutting. Cutting Plate Machine is used to cut boards with paper (such as Melamine). It is called 45 degree Push Table Saw.

(4) Once cut, the CNC automatic edge-banding machine applies hardwoods, HPLs and PVC edge-banding materials to all exposed raw edges. It will brush strong adhesives on board outline. There are 2 different Edge Banding Machines. One is automatic, the other is manual. This step includes edge banding, trimming. Also some parts need manual trimming once more for avoiding cutting hands.

(5) Next, our 4-axis CNC point-to-point machining center automatically completes drilling, routing, horizontal boring and precision sawing before assembled. Sometimes, we use the manual Precision Drill to drill the holes, and use Router Cutting Machine to curve some parts.

(6) Before package, we do painting with our water screen machine in painting room. There are 3 kinds of painting. Firstly, praying primer/base coat; secondly, colored painting at the base coating step; finally top coat painting after gas grinding again. The Water Screen Machine can absorb the paint in the air to make sure it is possible that the air in the painting room can be fresh and clean.

The ability to transform raw wood into complete, finished displays allows GONDO to provide merchandising solutions that exceed customers' expectations. Wood materials are usually used in display cabinets, showcases, wooden containers, wood frames, floor displays, shelves, logos, top boards, display stands, display racks, counter top displays and the other combined displays with various materials.

Hardwood (Solid Wood) Production

(1) High-quality hard wood of various grains and sizes begins processing in the milling facility to be cut.

(2) The wood is then off-loaded into molders and a CNC crosscut saw, where boards are optically examined for flaws or defects and graded accordingly.

(3) Broads are then sorted and sent to secondary milling operations, such as drilling, routing and sanding.

(4) Next, being stained. The Rhodes spray system applies stains, paints and sealers according to customer preference. Three coats are then applied to each component before final assembly to ensure maximum protection of the wood and finish for long-lasting and quality fixtures.

Metal & Stainless Steel & Aluminium Process

The metal plant is GONDO's largest growth facility. A complete wire division, a third CNC laser machine, a stainless steel department and CNC punching center, combined with our powder-coating system, automatic cut-off and bending machinery, robotic welding equipment, and CNC milling center make our metal workshop a superior facility capable of manufacturing a wide variety of metal and wire products.

(1) The metal material includes steel, iron, stainless steel, aluminum alloy or Zinc alloy, etc., coming in forms of sheet, tubes, rods, wire, mesh, etc.. The material has highly requirement of hardness and strength. GONDO prefers to high density board, even it causes 10% extra cost. Truly high quality is what we desired. "Strictly Crafts" is a cold steel to success, and also the purpose to services. With the luxuriant experiences and professional technology, GONDO would fully consider the factors to product risk assessment, import automatic facilities, and connect with international industry 4.0.

(2) The metal product process includes sawing, cutting, bending, folding, stamping, welding, milling, grinding, polishing, and testing. With automatic facilities, to make it more standardize and productivity. A complete list of machines in-house, includes rolling machines, metal sheet bending machines, bending machines, robot welding machines, laser cutting machines, digital groove-cutting machines, punching machines, drilling machines, grinding machines, CNC machines and other small auxiliary machines. Accessories need to be welded after cutting, while most manufacturers were still using spot welding, GONDO has used full length welding technology to be seamless connection, more beauty and quality. GONDO creates new standard for polishing. All welded need to be polished, and salient point should lower steel plate 0.1MM. Those processes make the finished product well scrubbed.

(3) Surface Handling Process. Powder coating, Chromed, Nickel Plated, Zinc Plated, SS Polished&Brushed&Anodized before assembled and packaged.

The regular usage of metal in displays, as follows,

1. SLATWALL ACCESSORIES, such as slatwall hooks, slatwall brackets, shelves, supports, baskets, etc..

2. DISPLAY RACKS, such as magazine racks, commodity holders, containers, dump bins, trash cans, shopping trolleys, store counter displays, floor standing display racks, etc..

3. Perimeter fixtures frames and upright, shelf, brackets.

4. COUNTERTOP DISPLAYS, shoe display, hat display, bag display, sock display, cosmetic display, jewelry display, etc..

5. ENDCAP AND GONDOLA DISPLAYS, frame, uprights, shelves, brackets, hooks, pop holder, etc..

6. TRADE SHOW DISPLAYS, such as store fixtures, metal parts for other POP displays, etc..

Acrylic, PETG, PET, PVC & other Plastics Process

Acrylic workshop becomes an important supplement to us as a professional manufacturer specializing in displays. Our acrylic products include POP, holder, box, tray, shelves, stand, tube, lift, step, block, award, rod and Cutting Service, ect. for different industries, such as glasses, cosmetics, jewellery, apparel, shoes and other displays that involve acrylic parts.

(1) Acrylic materials, come in sheet, rod, tubes with different finishes, such as glossy, semi-glossy, matte and frosted in regular thickness of 1.0, 1.5, 2.0, 3.0, 4.0, 5.0, 8.0, 10.0, 12, 15, 20, 25, 30mm, etc..

(2) Acrylic workshop equipped: precision panel sawing machines, CNC engraving machines, laser engraving machines, hot bending machines, flame polishing machines, diamond polishing machines, buff Polishers, drilling machines, routing machines, milling machines, sanding machines, Central dust collection system, silkscreen printing machines, etc..

(3) Acrylic working process: cutting, drilling, routering, trimming, polishing, paper tearing, logo printing, bending, moulding, gluing, assembling, packaging.

CNC Machining Center

CNC Machining Center, 300 sqm, 15 workers, 10 machines (CNC turning and milling equipments). With excellent designers and rich manufacturing experience, our factory provides customers with quality products, reasonable price and excellent service. We constantly import foreign advanced precision equipment equipments. Products are widely used in communication, medical, electronics, digital, watches, automobiles and other high-end fields.

We warmly and sincerely welcome customers from all over the world to visit our factory and expect to establish a long-term relationship with you. Want to update your retail space with high quality displays which are designed and manufactured from a trusted China company? Browse through our full range of solutions online or contact us for a bespoke quote. Any quote and question, please call or email us today.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23