High Carbon Steel Cutting Band Saw Blades for Meat Processing

Fujian Youyi Adhesive Tape Group Co., Ltd. / 2022-06-09

- Certification:ISO9001:2008, CE

- Tooth Form:Setting Left and Right

- Diameter:Blades

- Function:Cutting

- Shape:Band Saw Blade

- Coating:White Steel Saw Blade

=== Base Info ===

- Model NO.:HS9726

- Type:Carbide Saw Blade

- MOQ:3PCS

- Technical Process:Setting Left and Right, Teeth Punching, Hardening

- Materials:Sk75, SAE10575, 65mn

- Package:Sea Worthy Carton

- Sharp:Yes

- Teeth Hardening:Per Customerization

- Teeth Punching:Yes

- Transport Package:Carton

- Specification:0.56*16mm*1650mm

- Trademark:HongSheng

- Origin:Jiangxi

- HS Code:82022090

- Production Capacity:10000PCS

=== Description ===

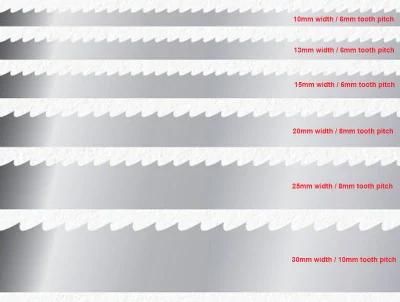

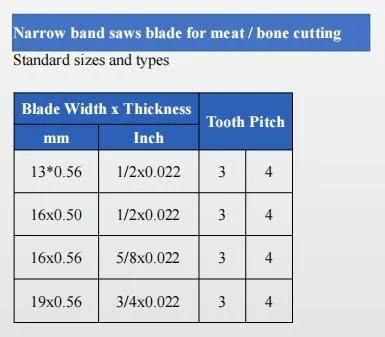

3. Regular size.

3. Regular size. 4. Applications.

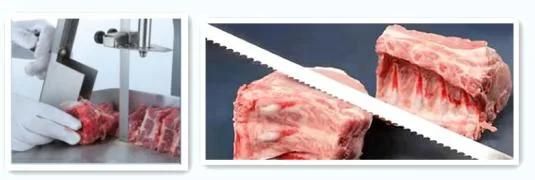

4. Applications.

5. Package.

6. Our company

6. Our company

CATHY TAN

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23