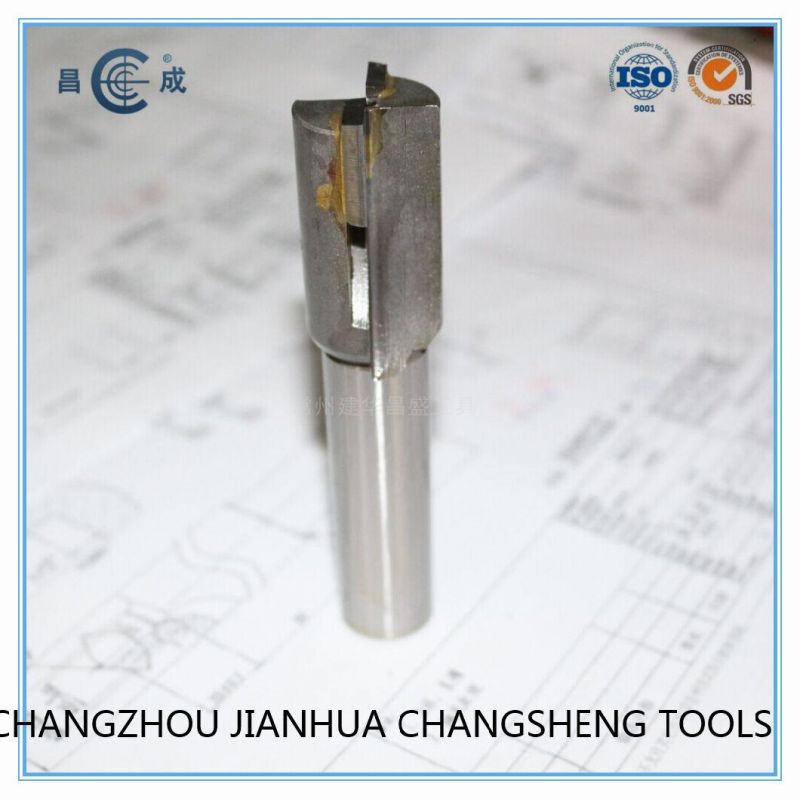

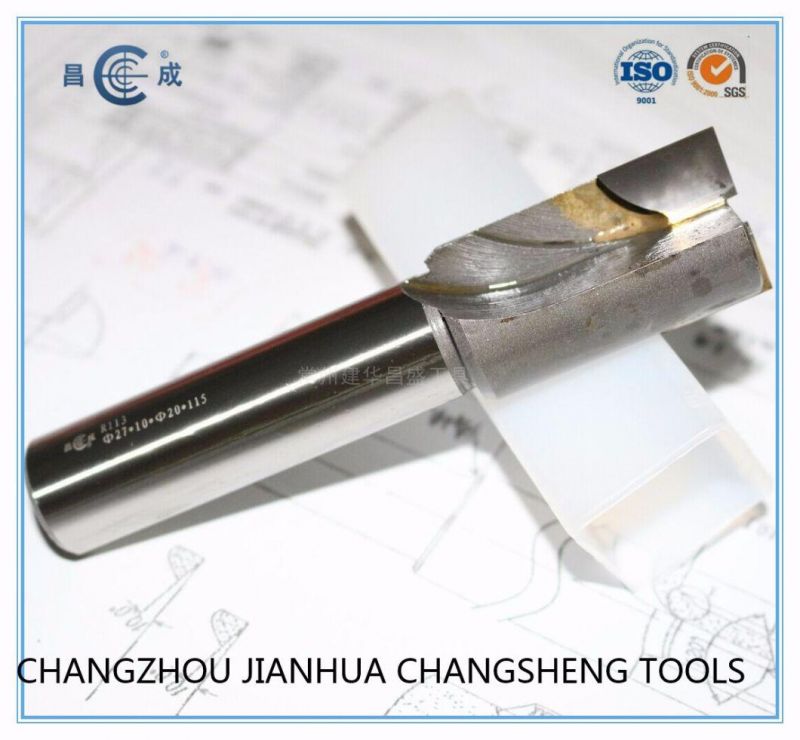

HSS Welded 27 Face End Mill with Carbide Insert for Processing Plane

Shanghai Shicheng Packaging Machinery Co., Ltd. / 2022-06-09

- Coating:Uncoated

- Tooth Form:Straight Tooth

- Tooth Space:Sparse Tooth

- Structure:Indexable Type

- Material:High Speed Steel

- Type:Face Milling Cutter

=== Base Info ===

- Precision:High Precision

- HRC:45,55,60,65 HRC

- End Mill Flute:1,2,3,4,5,6,8,12

- Flexural Strength:2500-4000n,mm2

- Length:30-200mm (on Your Requirement)

- Diameter:3mm-40mm (on Your Requirement)

- Usage:General Purpose,High Speed Cutting

- Controlling Mode:CNC System

- Certificate:ISO9001:2008

- OEM:Yes

- Transport Package:Protective Sleeve+Plastic Box+Paper Box+Carton

- Trademark:Changcheng

- Origin:Changzhou Jiangsu, China

- HS Code:8207709000

- Production Capacity:300000,Month

=== Description ===

Basic Info.

Precision High Precision HRC 45/55/60/65 HRC End Mill Flute 1/2/3/4/5/6/8/12 Flexural Strength 2500-4000n/mm2 Length 30-200mm (on Your Requirement) Diameter 3mm-40mm (on Your Requirement) Usage General Purpose/High Speed Cutting Controlling Mode CNC System Certificate ISO9001:2008 OEM Yes Transport Package Protective Sleeve+Plastic Box+Paper Box+Carton Trademark Changcheng Origin Changzhou Jiangsu, China HS Code 8207709000 Production Capacity 300000/MonthProduct Description

Raw materialGuhring of Germany

Konrad of Germany

Teagutec of Korean

Kennametal of American

Sumitomo of Janpan

CB-CERATIZIT, XiaMen Golden Egret, Zhuzhou, Nanchang, Zi gong,

100% original tungsten, no recycle, Co12%, bending strength >5000N/mm2. So that carbide end mill have stable and high quality.

All of the raw material is The original raw material, purified material.

Super Coating

| AlTiN | TiAIN | TiSiN | Nano | |

| Hardness(HV) | 3200 | 2800 | 3600 | 42(GPA) |

| Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 |

| Oxidation Temp(°) | 900 | 800 | 1000 | 1200 |

| Friction Coeffient | 0.3 | 0.3 | 0.45 | 0.4 |

| Color | Black | Violet | Copper | Blue |

Imported CNC machine1.Tru Tech from USA

2.Jack Mill from TaiWan province of CHINA

3.ANCA from Australia

Imported Test Machine1.Zoller genius 3s Zoller TFT-Display

2.SEVEN OCEAN part of Hexagon

Strict measurement sequence Five step test1.Test the rod after grinding

2.Test when produce the tools

3.Test all parameter the After the tools finished after CNC machine

4.Test flutes After coating

5.Test the packing before shipping

Packaging & Shipping1.Laser brand and dimensions on the body of cutters, print labels.

2.5PCS or 10PCS each group,sealed with air bubble wrap, pack into bigger carton.

3.Marking and Laser brand can be our and yours, or no. All depend on your require.

Delivery Time1.For samples, we dispatch your tools in 2-7 workdays.

2.For formal orders, We delivery tools to you in 7-30 workdays, it will depond on your order quantity.

Our Advantage1.Professional: Engaged in designing and producing solid carbide cutting tools since 1993, so rich experience and more professional.

2.High quality: Adopted advanced ANCA CNC machine with best raw material from Germany and Sweden, also 100% Zoller measuring and inspecting.

3.Best service: Produce according to your requirement and provide after-sale help if you need.

4.Price: With our own factory, you can get more competitive price from us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23