High Speed CNC Automatic Round Knife Cutting Fabric Cloth Cutting Equipment for Sofa Garments

Guangzhou Argion Electric Appliance Co., Ltd. / 2022-06-27

- Voltage:110V , 220V , 380V

- Power Source:Electric

- Automatic Grade:Automatic

- Warranty:1 year

- Certification:CE, ISO

- Effective Cutting Area:2500mm*1600mm

=== Base Info ===

- Cutting Thickness:0.1-50mm

- Cutting Accuracy:0.1mm

- Cutting Speed:Max. 1500mm,S

- Material Fixed Mode:VAC-Sorb

- Location Mode:Infrared Laser

- Fan Power:9kw

- Drive Servo Motor:Panasonic , FUJI , Yaskawa Optional

- Support File:Dxf & Plt

- Transport Package:Wooden Box

- Specification:3600m*2500*1315

- Trademark:kangjia

- Origin:Jinan China

- HS Code:8461500090

- Production Capacity:100 Sets , Month

=== Description ===

Multifunctional heads optonal

Machine Introduction:

Automatic CNC Oscillating Knife Cutting Fabric Leather PVC Cutter Machines for sale

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance;

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life;

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

4. Kangjia digital cutting machine was designed easy to install, set-up and operate;

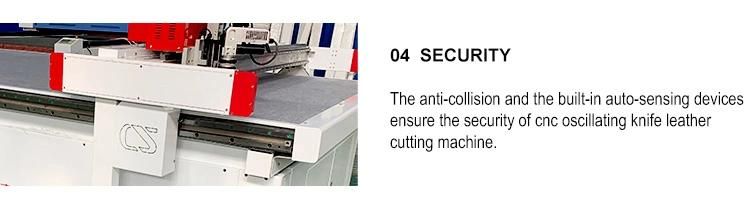

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety;

6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

Machine details:

Cutting materials display:

About us

Kangjia CNC Equipment Co.,Ltd. has focused on oscillating knife cutting machine for over 5 years, It is a comprehensive service company specializing in the production, sales and technical service of knife cutting machine. Our factory covers 10000 square meters, with 150 staffs in total. The production capacity is about 100 unit / month. Warmly welcome to visit our factory.

With the repaid development of global economic, man's environmental awareness become more and more strength. In this case, the oscillation knife is came into the market and approved by many flexible materials' industries.

Training to install (2options):

A. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone/MSN/ICQ and so on, when you meet some problems of installation, using or adjusting.B. You can come to our factory for training. We will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments all sorts of tools and testing facility,we will also provide accomadation during training period. Training Time: 1-10 working days.

Certifiction

Our company has been certified by ISO9001, SGS, CE certification.

Main Parts:

1

Servo Motor

Panasonic (Japan)

2

Linear Guide Rail

PMI (Taiwan, China)

3

Ball Screw

TBI (Japan)

4

LCD Control Panel

Kangjia (China)

KWH: 1A@12VDC, 450mA@24VDC

5

Vacuum Adsorption Platform

Kangjia (China)

6

Underlay

Ammeral Beltech (Netherlands)

2.5mm or 4mm can be chosen

Exhibition

Packing and delivery

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Our service

Before sales:

- Reply you within 24 hrs for your inquiry or question.

- Learn your detail requirements and what material you will cut. Then recommend the good solution that suit for you.

- Sign sales contract and receive the deposit.

- Arrange production.

- Track the production schedule.

- Debug machine.

- Pack with wooden box and shipping.

1. 12 months warranty for the whole machine.

2. Technical support by phone, email or WhatsApp / Skype around the clock.

3. Friendly English version manual and operation video CD disk.

4. If necessary, the fields service can be provided.

FAQ

Q: 1. How can I choose a suitable Knife cutting machine?

A: Please provide us some info, then we can recommend you the suitable machine:

1)What materials are going to cut? Are they rolled or not? Breathable or not?

2)What's the largest size of original materials?

3)What's the thickness of materials?

4)Excepting for cutting, do you need more functions, like drawing, punching holes, scanning, feeding, CCD camera, etc.?

Q: 2. Can you design a machine for me depending on my requirements?

A: Of course, we will give our professional suggest and discuss details with you for the machine which matches all the requests with best cost performance.

Q: 3. What should I do if the machine has any problem in future?

A: We supply online/phone technical support and door to door service. Anything confuse or not goes well, pls contact us in the first time.

Q: 4. What's the warranty policy?

A:Standard warranty is 12 months upon delivery.

Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period.

Problems caused by wrong operate will also well-solved, but not for free.

We also supply life long after-sales service. No matter when, you can count on our best service for your machine.

Q: 5. If I don't know this machine before, how can I operate it?

A: We supply face to face training and provide operating video, user manual, and telephone calls to help.

It's easy to learn, one inexperience people can learn it within one day.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23