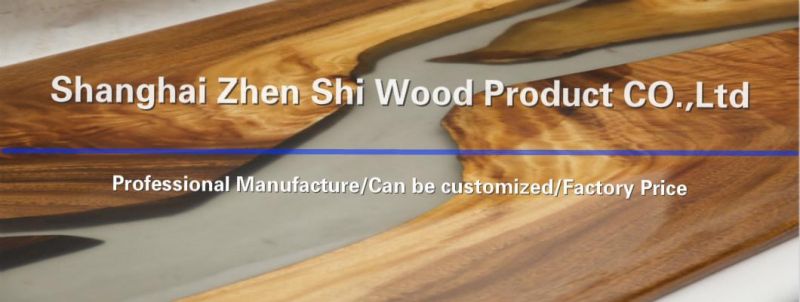

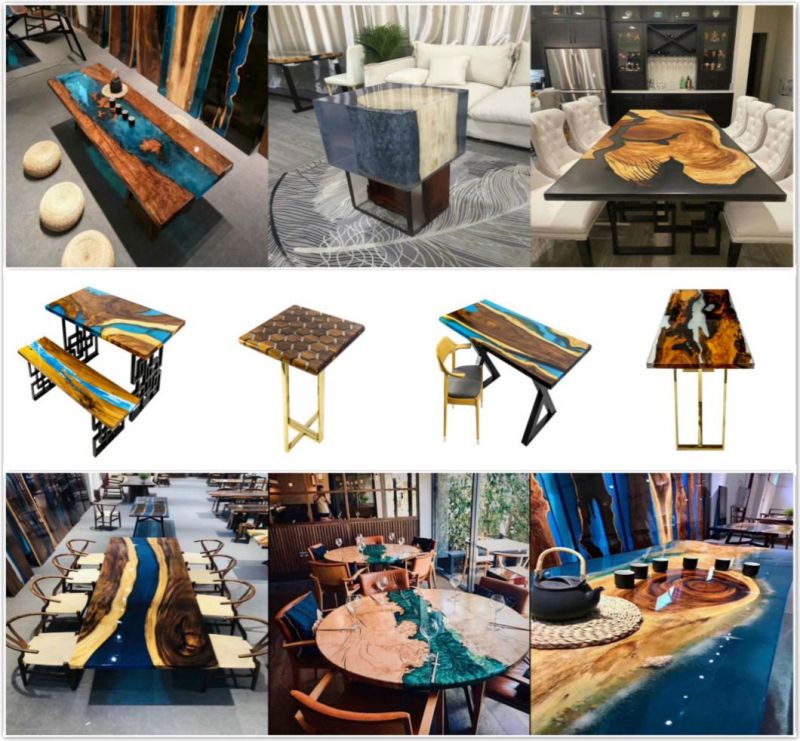

Resin Epoxy Table Top High Glossy Tea Table Dining Table Coffee Table

Ninghai Plastic Eighth Factury / 2022-06-24

- Style:Modern

- Material:Solid Wood or with Epoxy Inlay

- Wood Style:Solid Wood or with Epoxy Inlay

- Folded:Unfolded

- Customized:Customized

- Condition:New

=== Base Info ===

- Usage:Hotel, Home, Restaurant, Cafe, Garden

- Shape:Rectangle

- Rotary:Fixed

- Color:Blue, Transparent, Green, Yellow, Red, Black....

- Resin Hardness:3h

- Resin Color:Transparent, Blue, Green, Red, Gold, etc

- Customized or Not:We Can Customize

- Resin High Temperature Resistant:160 Degrees

- Resin Transparency:90% and Higher

- Wood Treatment:Wood Kiln Dried at 8%-12% Moisture

- Finishing:Finished with Wax Oil or UV Lacquer

- Assembled Way:We Make Pre-Drilled Holes with Metal Inserts Inlay

- Table Leg Materials:Iron Steel or Stainless Steel

- Wood Materials Species:Suar, Walnut, Ash, Maple, Ebony, Teak etc

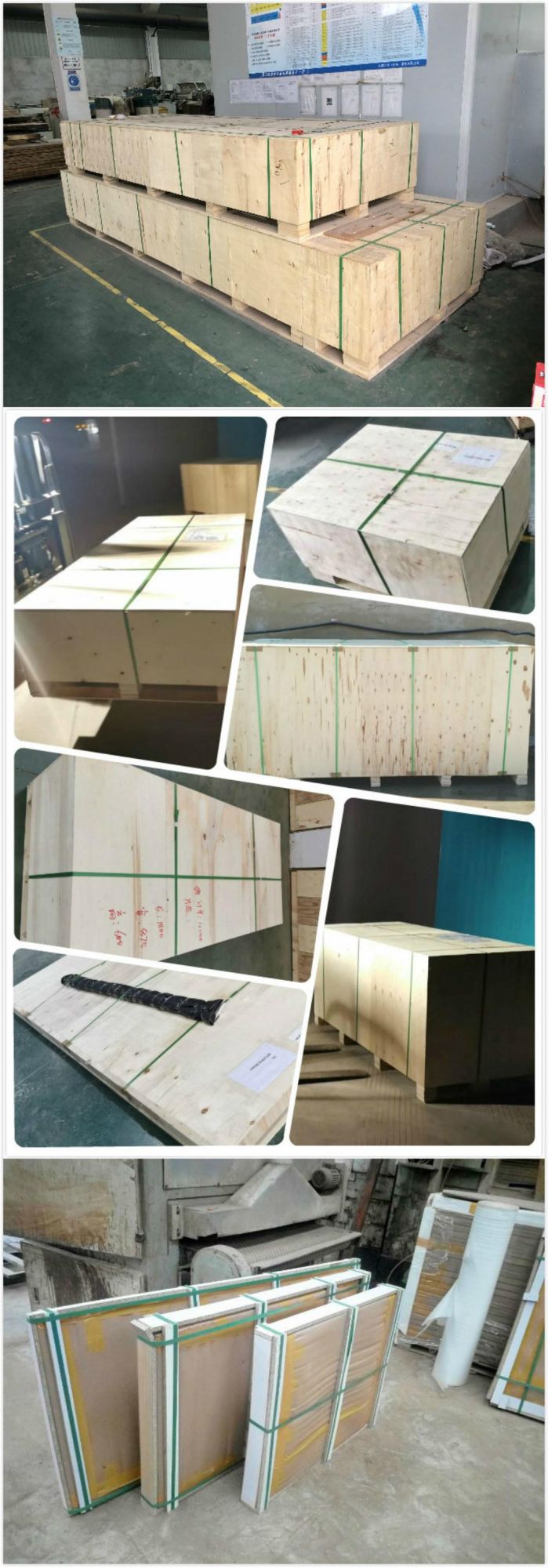

- Transport Package:Carton Box Package Individually

- Specification:350-5000*350-1500*350-1100mm

- Trademark:Zhen Shi Wood

- Origin:China

- HS Code:9403609990

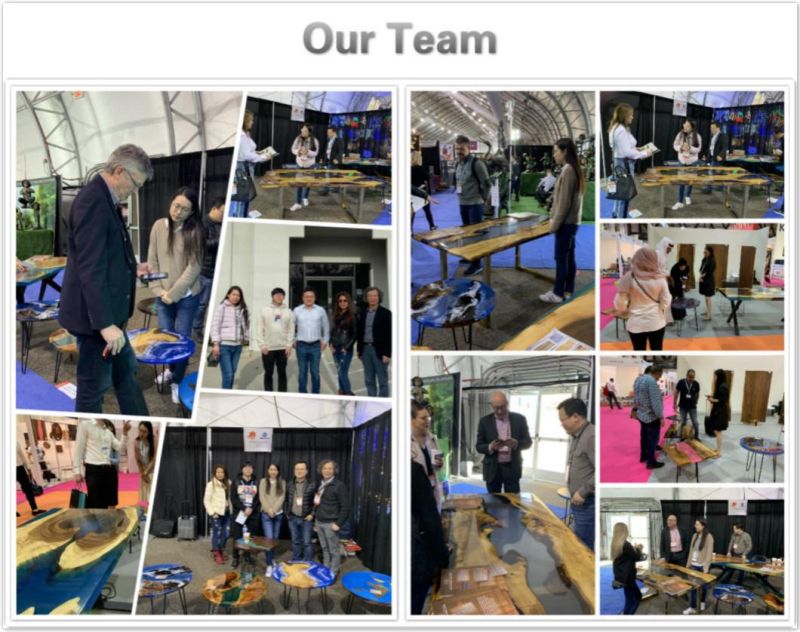

- Production Capacity:10000 Square Meters Per Month

=== Description ===

Basic Info.

Usage Hotel, Home, Restaurant, Cafe, Garden Shape Rectangle Rotary Fixed Color Blue, Transparent, Green, Yellow, Red, Black.... Resin Hardness 3h Resin Color Transparent, Blue, Green, Red, Gold, etc Customized or Not We Can Customize Resin High Temperature Resistant 160 Degrees Resin Transparency 90% and Higher Wood Treatment Wood Kiln Dried at 8%-12% Moisture Finishing Finished with Wax Oil or UV Lacquer Assembled Way We Make Pre-Drilled Holes with Metal Inserts Inlay Table Leg Materials Iron Steel or Stainless Steel Wood Materials Species Suar, Walnut, Ash, Maple, Ebony, Teak etc Transport Package Carton Box Package Individually Specification 350-5000*350-1500*350-1100mm Trademark Zhen Shi Wood Origin China HS Code 9403609990 Production Capacity 10000 Square Meters Per MonthProduct Description

Epoxy Wood Table Material:

Epoxy part-- we use 3H hardness Epoxy, transparency higher than 90%, high temperature-resistant at 160 degrees

Wood part--- we proceed from kiln dried wood ( moisture content below 12% ), which can avoid no crack and warp during use.

We can customize any different model according to your request, or you can select interested model from our current catalogue, welcome to send us your idea.

Our factory land 6000m², our production progress is completely mechanized:

Our factory land 6000m², our production progress is completely mechanized:

Logs → Cut into sawn timber → Kiln Dried below 12% → Mositure Content Balance → Materials Choosing → Plan double faces → Cutting into available size sawn panels → Gulleting → Plan 4 faces → Sanding faces to be smooth → Make the wood part design according to order → Fill inlay Resin Epoxy and procced into resin table → Package and Stock

We package each table top with Shrink Wrapping Film, then package each table set in carton box individually, then packaged in strong woo d pallet, we use MDF boards and corner protectors around the pallet to promise its stability, when loading into container, we put airbags between each pallet to avoid shake during delivery.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23