Efficient Paint Baking Booth with Electric Infrared Lamps for Vehicles

Hangzhou Mig Packaging Co., Ltd. / 2022-06-23

- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Downdraft

- Heating Mode:Infrared Ray

=== Base Info ===

- Model NO.:E501

- Paint Mist Treatment:Dry-type

- Condition:New

- Plenum (Height):400mm

- Basement:300mm (High)

- Floor Filtration Areas:10.4m2

- Grids Carrying Capacity:650kg,Wheel

- Walls:50mm Thick Rock Wool Panels

- Illumination:>800lux

- Empty Loaded Air Speed:0.20m,S

- Heats:Electric Infrared Lamps

- Maximum Working Temperature:80 Celsius

- Voltage:380V, 50Hz, 3pH

- Rated Power:45kw

- Transport Package:Goods Packed by Polyfoam and Loaded on Metal Frame

- Specification:6900X4000X2650mm

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

=== Description ===

Basic Info.

Model NO. E501 Paint Mist Treatment Dry-type Condition New Plenum (Height) 400mm Basement 300mm (High) Floor Filtration Areas 10.4m2 Grids Carrying Capacity 650kg/Wheel Walls 50mm Thick Rock Wool Panels Illumination >800lux Empty Loaded Air Speed 0.20m/S Heats Electric Infrared Lamps Maximum Working Temperature 80 Celsius Voltage 380V, 50Hz, 3pH Rated Power 45kw Transport Package Goods Packed by Polyfoam and Loaded on Metal Frame Specification 6900X4000X2650mm Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

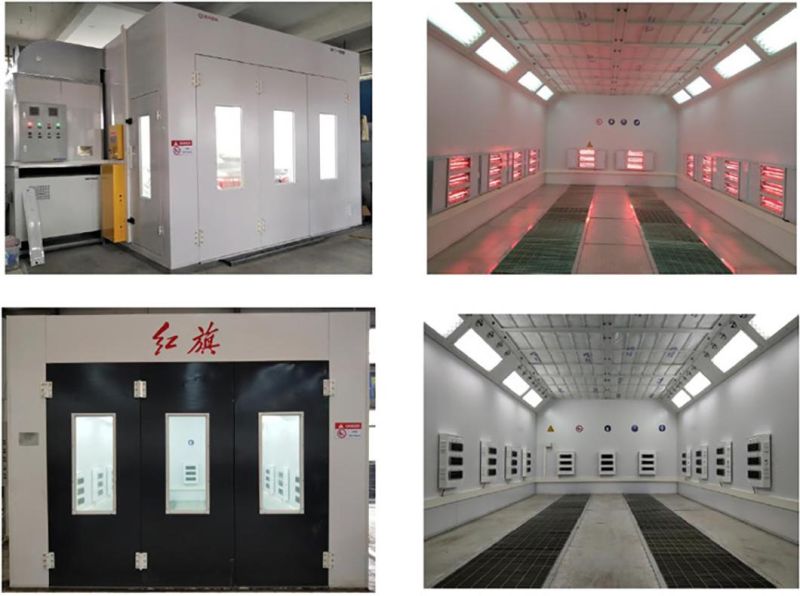

Efficient Paint Baking Booth with Electric Infrared Lamps for Vehicles

1.HIGHLIGHTS

INFITECH paint spray booth E501 is practical model targeted for customers who request practical solution, but also quality paint refinishes. It comes with smooth and consistent downdraught airflow, and direct-drive fan units, facilitating easier maintenance and safer operation.

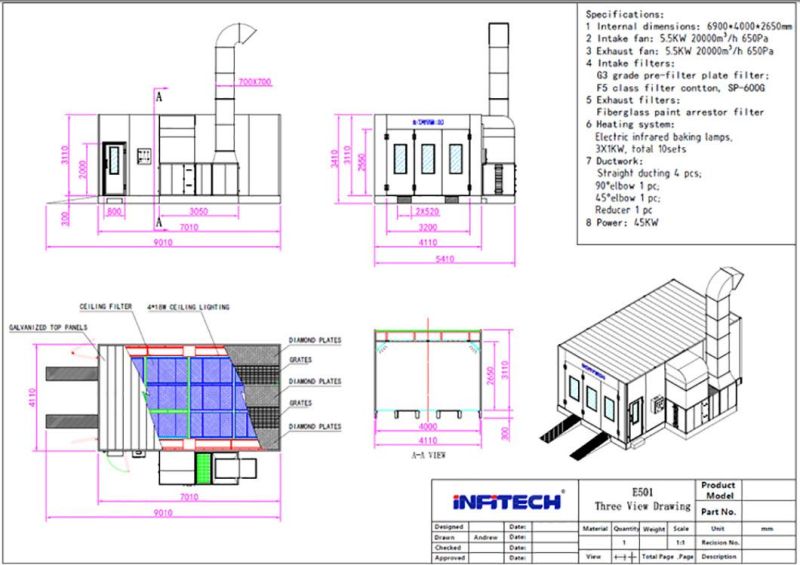

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | E501 Auto Paint Spray Booth |

| Internal dimensions | 6900 X 4000 X 2650mm (L X W X H) |

| External dimensions | 7010 X 5410 X 3410mm (L X W X H) |

| Airflow | Downdraught |

| Plenum (height) | 400mm |

| Basement | 300mm (high) |

| Floor filtration areas | 10.4m2 |

| Grids carrying capacity | 650kg/wheel |

| Basement | 2 rows of grids and 3 rows of diamond plates |

| Entrance door | 3200x2550mm (WxH), 1 set |

| Service door | 800x2000mm(WxH), 1 set |

| Walls | 50mm thick rock wool panels |

| Upper lights (LED) | 8 sets, each 4 X 18W, 576W total |

| Illumination | >800LUX |

| Filters | Plate filter, high efficiency ceiling filter, floor filter |

| Intake/Exhaust unit | Direct-drive big impeller fans 2x5.5KW intake fan, 20,000m3/h |

| Empty loaded air speed | 0.20m/s |

| Heats | Electric infrared lamps 10 sets, 3 x1kw/ set |

| Heats - OPTION | Diesel or gas heating with heat exchanger |

| Maximum working temperature | 80ºC |

| Controls | Control box with standard functions |

| Voltage | 380V, 50Hz, 3ph |

| Rated power | 45KW |

3.DETAILS

DESIGN DRAWING

Practical paint spray booth - E501 RANGE

Practical paint spray booth - E701 RANGE

FAQ

Q: I might need a lift to be installed inside the paint spray booth. Can you help me with this?

A: Yes. We can also supply the lift.

It is also okay that you buy the lift locally. But you need to send us the detailed information of the lift. So we can consider it when we design the basement.

Q: Can you supply paint spray booth for industrial manufacturing, like furniture, heavy equipment etc.?

A: Certainly. Infitech takes pride in delivering customized paint spray booth projects. Please tell us your individual needs, we will discuss and provide you with corresponding solution for approval.

Q: I need pneumatic ramp inside the booth.

A: Yes. That's okay.

Q: How to install the paint spray booth?

A: No worries. Customers will be provided with installation steps, instructions, drawings and electric schematic so they learn and know how to install the booth. Moreover, we will be by your side, offer timely technical instructions (i.e. by using instant messaging) and check if the installation is correct or not upon receipt of your feedbacks.

Q: How often should we change the filters?

A: Usually, it depends on the actual operation situation of the paint spray booth. However, there is universal guide concerning the replacement intervals. The guidance will be supplied to customers for reference.

Q: How do I know the filters become clogged?

A: It is recommended to have the maintenance schedule of the paint spray booth recorded in details. So you can have an idea when the filters are replaced last time, and follow the supplied maintenance intervals to replace the filters.

However, there is signal that indicates the filters get blocked. Observe if the pressure inside the booth is normal or not. Usually, the blocked filters will result in abnormal pressure.

Q: Do you supply preparation stations and paint mixing room?

A: Yes.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23