Carbide Tipped Band Saw Blade for High Temperature Alloy Steel

HUTTON INDUSTRY.LTD / 2022-06-09

- Certification:ISO9001:2008, CE

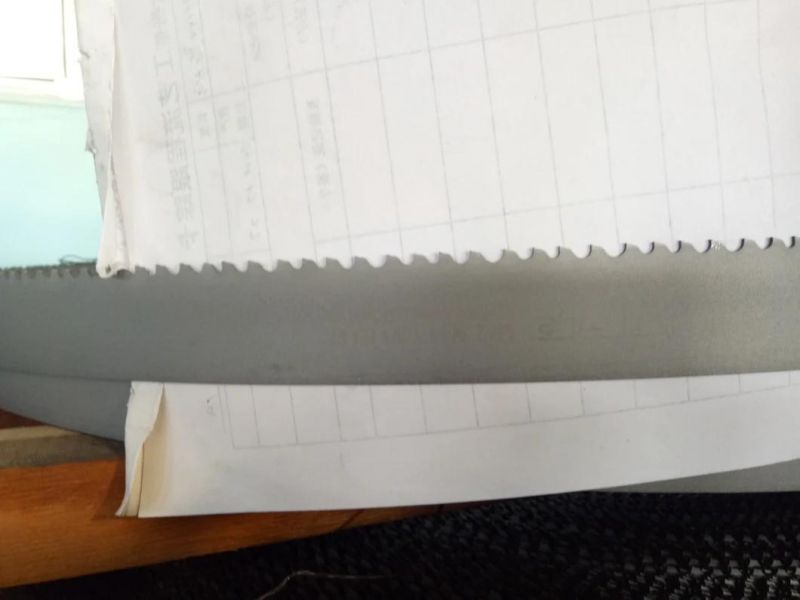

- Tooth Form:Alternate Tooth

- Function:Cutting

- Shape:Band Saw Blade

- Type:HSS Saw Blade

- Blade Thickness:0.9mm, 1.1mm, 1.3mm, 1.6mm

=== Base Info ===

- Model NO.:34*1.1

- Blade Material:HSS

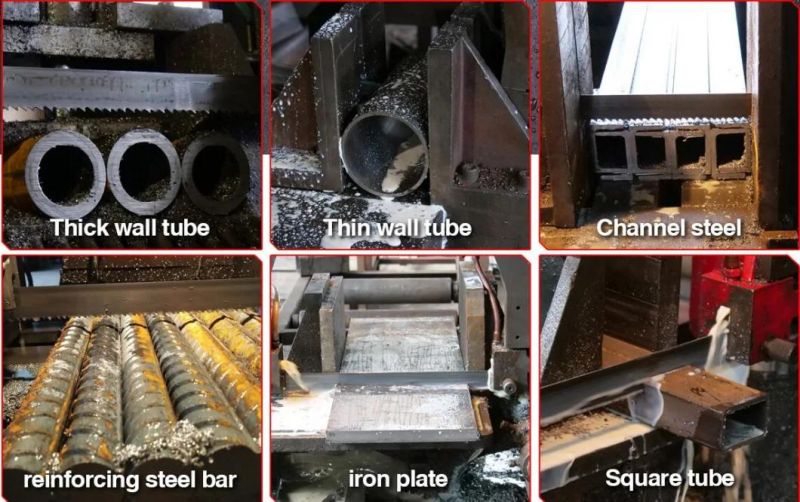

- Cutting Material:Metal, Stainless Steel, Carbon, Aluminum, Alloy

- Blade Width:27mm, 34mm, 41mm, 54mm, 67mm, 80mm

- Teeth Per Inch:5,8, 3,4, 4,6,2,3

- Process Type:Hot Press

- Cutting Mode:Cold Cutting

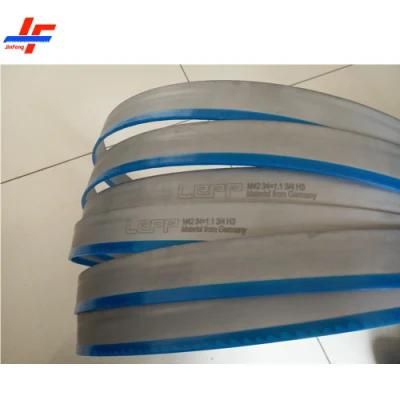

- Transport Package:Plywood Case Packing

- Specification:27*0.9mm

- Trademark:LEPP

- Origin:Shandong China

- HS Code:8202991000

- Production Capacity:30millions Meters,Year

=== Description ===

Basic Info.

Model NO. 34*1.1 Blade Material HSS Cutting Material Metal, Stainless Steel, Carbon, Aluminum, Alloy Blade Width 27mm, 34mm, 41mm, 54mm, 67mm, 80mm Teeth Per Inch 5/8, 3/4, 4/6,2/3 Process Type Hot Press Cutting Mode Cold Cutting Transport Package Plywood Case Packing Specification 27*0.9mm Trademark LEPP Origin Shandong China HS Code 8202991000 Production Capacity 30millions Meters/YearProduct Description

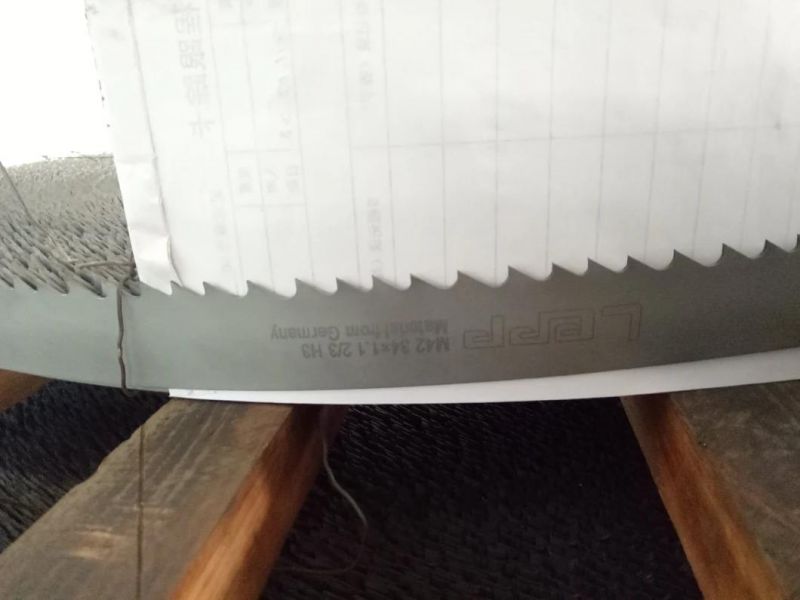

Carbide Tipped Band Saw Blade for High Temperature Alloy SteelBrief introduction:

Bi-Metal band saw blades offer more cutting versatility and longer life through their unique construction, where a ribbon of high speed steel is electron-beam welded to a spring tempered alloy backer. The high speed steel edge offers durable, tough cutting ability, while the tempered alloy backer provides the fatigue resistance for long blade life.

Features:

1)Resists heat, abrasion , and shock;

2)Can be used in horizontal and vertical machines;

3)Idea for contour and general purpose cutting;

4)alloy backer provides the fatigue resistance for long blade life;

5)The high speed steel edge offers durable, tough cutting ability.

Specifications

| Product Name | Professional Hss Bi-metal Band Saw Blade For Saw Blade Sharpening Machine |

| Material | M51/M42 |

| Specification | 27mm*0.9 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 34mm*1.1 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 41mm*1.3 1.4/2TPI 1/1.5TPI 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 54mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 67mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 80mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI |

| Material Cutting | carbon steel/mold steel/Alloy steel/Stainless steel |

| Advantages | Materials feature m42 bi-metal bandsaw blade is a double metal structure: B318 backing, fatigue strength; M42 tooth material, 8% cobalt content, tooth hardness HRC67-69. The main advantage of bi-metal band saw blade is: 1. High wear resistance and high red hardness; 2. Serrated not easy to break; 3. Long service life. |

| Packages | the blades with the plastic cover and then 10 pcs into one carton/box |

| Min order | With the customers' requirements |

| Delivery time | 7 days after the advanced payment |

Our Factory

Jinan North Jinfeng Sawing Machine Co., Ltd. is an outstanding manufacturer band sawing machine and band saw blades and a professional manufacturer of machinery sawing equipment. Over the years, our company has strictly controlled the quality of the products and paid much attention to after-sale services. Our products have passed the ISO9001:2008 quality system certification. With scientific management, advanced technology and high innovation, our company has won high praise of global customers.

Packing

FAQ

Q1: Do you provide samples? Is it free or extra?

A1: Yes, we could offer the sample, buyer pay for the freight charge .

Q2: What's your terms of payment?

A2: For small trial order we accept the payment of Paypal and western union; For the items order that we are not in stock; the payment 30% deposit after order confirmed, The 70% balance should be received before the goods ship out, If you have any other question Please feel free to contact us any time.

Q3:What about the lead time and shipment?

A3: Samples need 2-3 days, but formal order according to your quantity, we can discuss before sign contract. We usually ship by DHL, UPS, FEDEX or TNT, It usually take 3-5days to arrive, Airline and sea shipping also optional.

Q3: How to proceed an order for saw blade?

A3: After received your requirements or application, we quote you our lowest price, Thirdly customer confirms the samples and places deposit for order, then we arrange the production.

Q4: How to deal with the faulty?

A4: Our goods are produced with strict quality control system and the defective rate will be less than 0.2%.

During the guarantee period we will send new saw blade with new order for small quantity, For defective batch goods, we will repair them and re-send them to you or we can discuss the solution including re-call according to the situation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23